Crushed material feeding machine

A technology of crushing and feeding machine, applied in fertilizer distributors, fertilization devices, applications, etc., can solve the problems of low efficiency, high labor intensity for farmers, slow speed, etc., and achieve high efficiency, labor cost saving, and uniform feeding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to facilitate the understanding of those skilled in the art, the invention will be further described in detail below with reference to the drawings and embodiments.

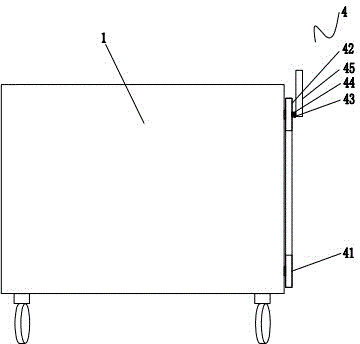

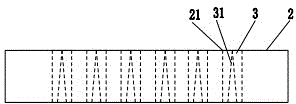

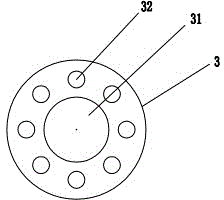

[0014] as attached Figure 1-3 As shown, a crushed material blanking machine includes a sliding box 1 for placing the crushed material, and a rotating shaft 2 is installed on the inner bottom of the sliding box 1 through a bearing, and a rotating shaft hole 21 is evenly arranged on the rotating shaft 2. A through hole is provided at the corresponding position of the rotating shaft hole 21 at the bottom of the sliding box 1, and a feeder 3 is provided in the rotating shaft hole 21; a driving mechanism 4 connected with the rotating shaft 2 is provided outside the sliding box 1, and the driving mechanism 4 drives the rotating shaft 2 Rotate to make the rotating shaft hole 21 align with the through hole, when the rotating shaft hole 21 was aligned with the through hole, the crushed powder was discharg...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap