Leather shoe surface flattening machine

A technology of flattening machine and leather shoes, which is applied in the direction of shoe-making machinery, footwear, clothing, etc., can solve the problems of labor and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

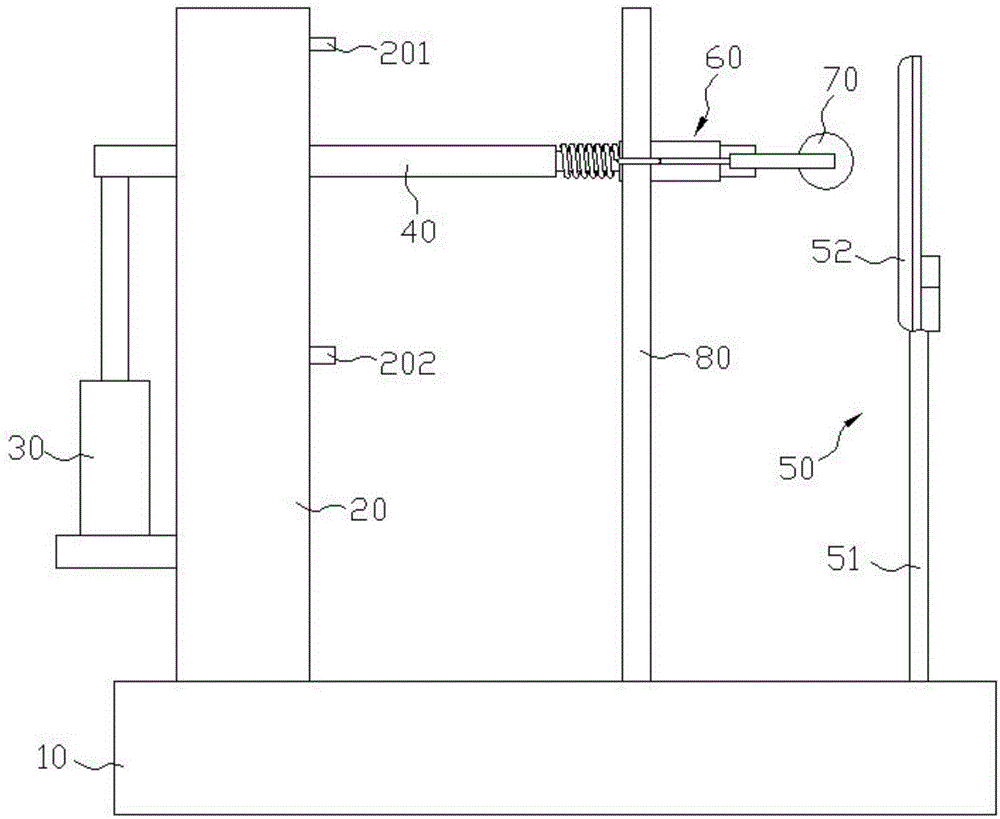

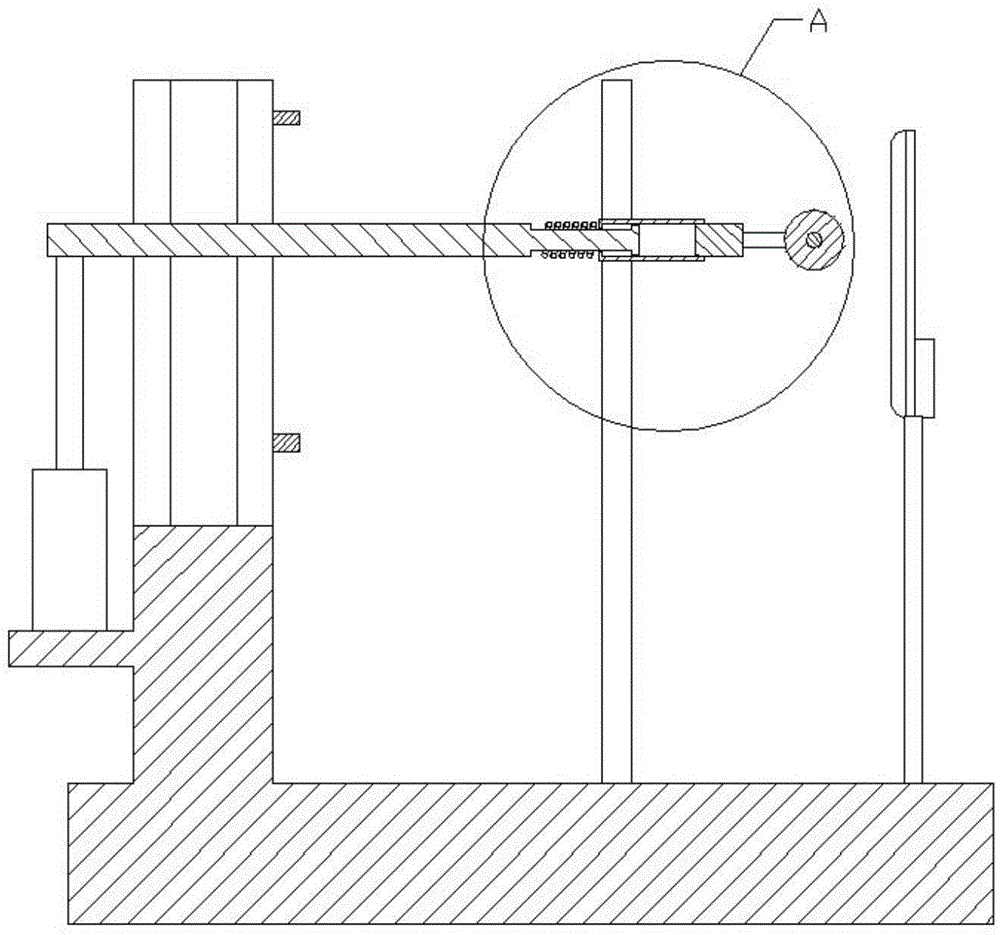

[0023] Such as figure 1 , a flattening machine for the surface of leather shoes, including a base 10, a pillar 20, a cylinder 30, a lifting rod 40, and a shoe support frame 50.

[0024] Such as figure 1 , the pillar 20 is arranged vertically, and the bottom of the pillar 20 is fixedly installed on the base 10 .

[0025] Such as figure 1 , the cylinder 30 is fixedly installed on the side wall of the pillar 20, and the piston rod of the cylinder 30 is vertically arranged;

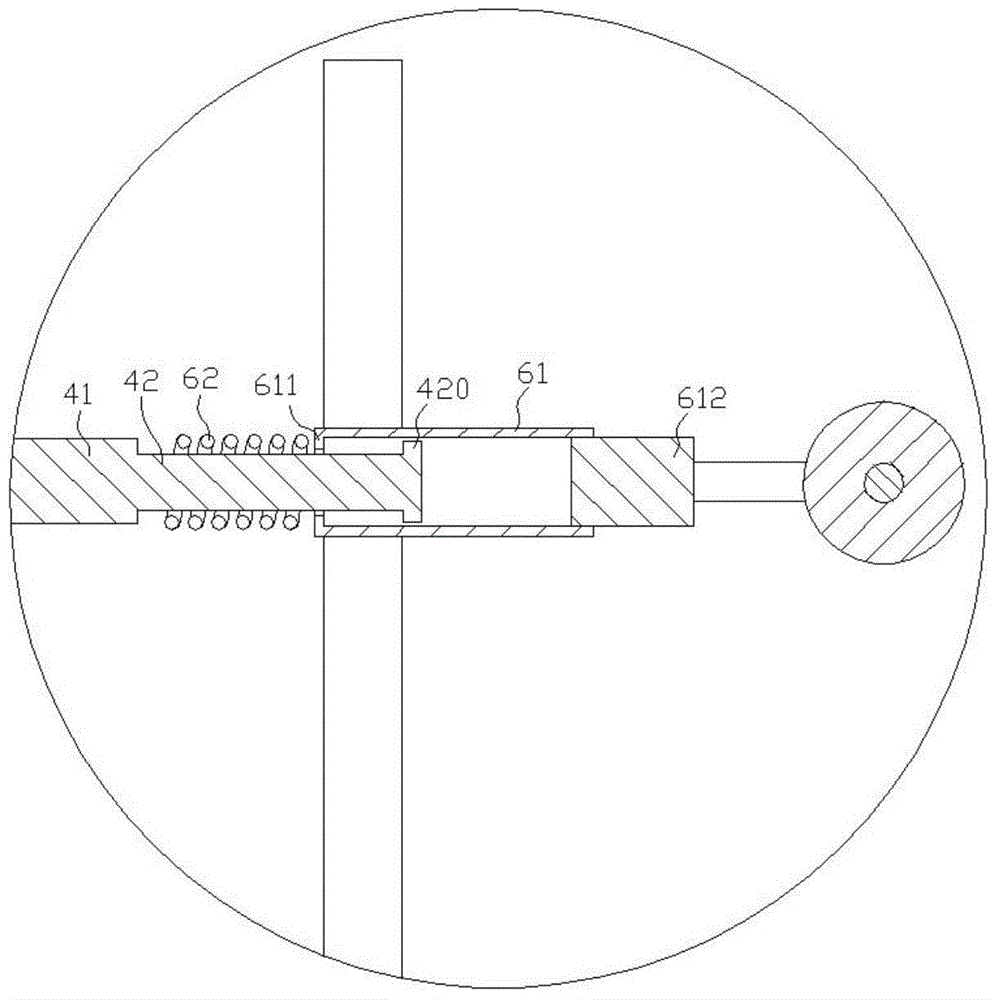

[0026] Such as figure 1 , the lifting rod 40 is arranged horizontally, one end of the lifting rod 40 is fixed on the end of the piston rod of the cylinder 30, and the other end of the lifting rod 40 is equipped with a telescopic head 60, which can be stretched along the center line of the lifting rod 40 Movement, the top of telescoping head 60 is equipped with flattening roller 70, and flattening roller 70 is horizontally arranged, and the center line of flattening roller 70 is perpendicular to the center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com