Variable track-ultrasonic elliptic vibration type auxiliary consolidation abrasive polishing machine

A technology of elliptical vibration and consolidation of abrasive particles, which is used in grinding/polishing equipment, surface-polished machine tools, and parts of grinding machine tools. The problem is that the processing efficiency of the polishing device is not large, and the processing efficiency and processing accuracy are high, and the effect is not easy to be damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

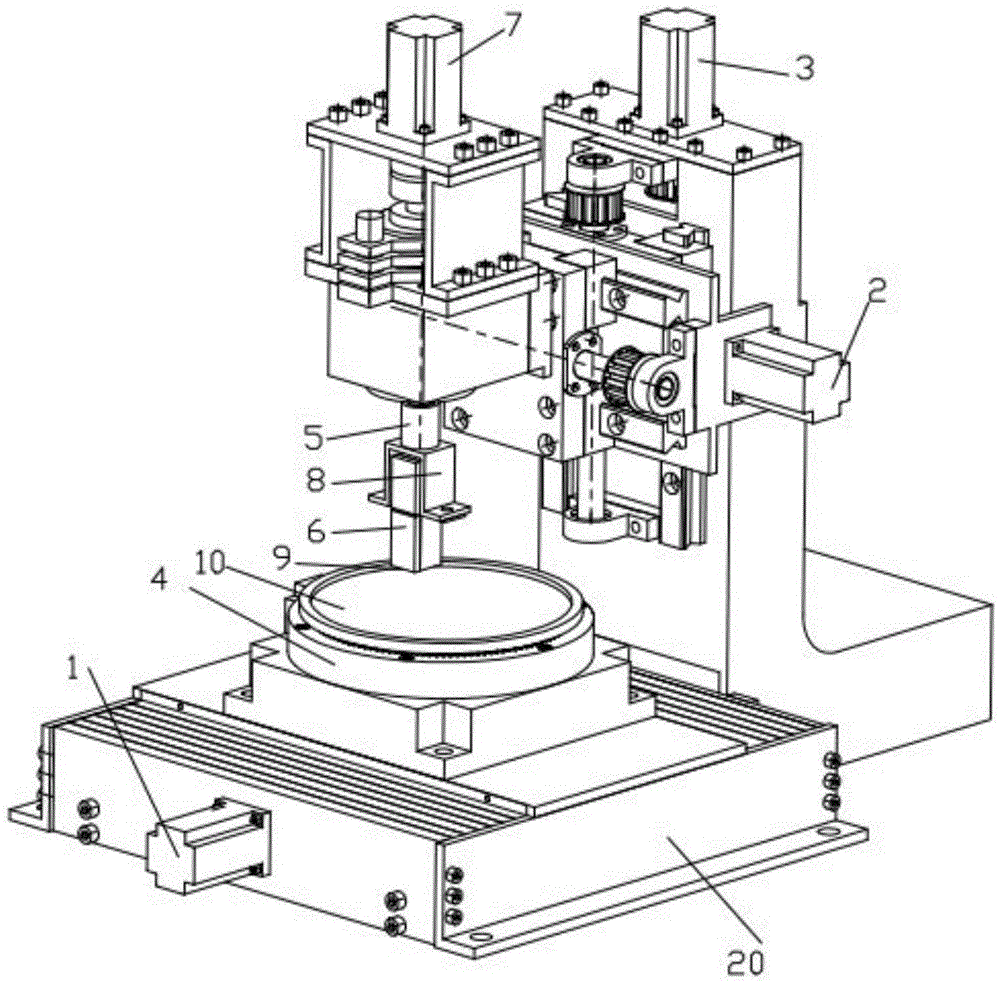

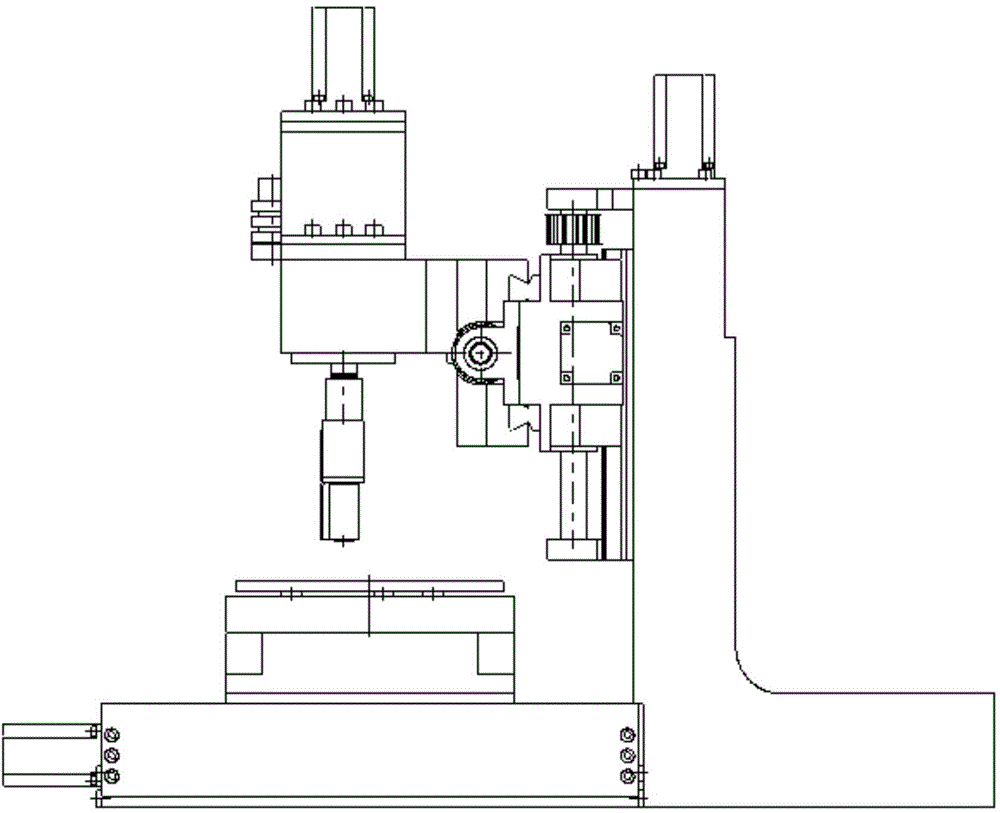

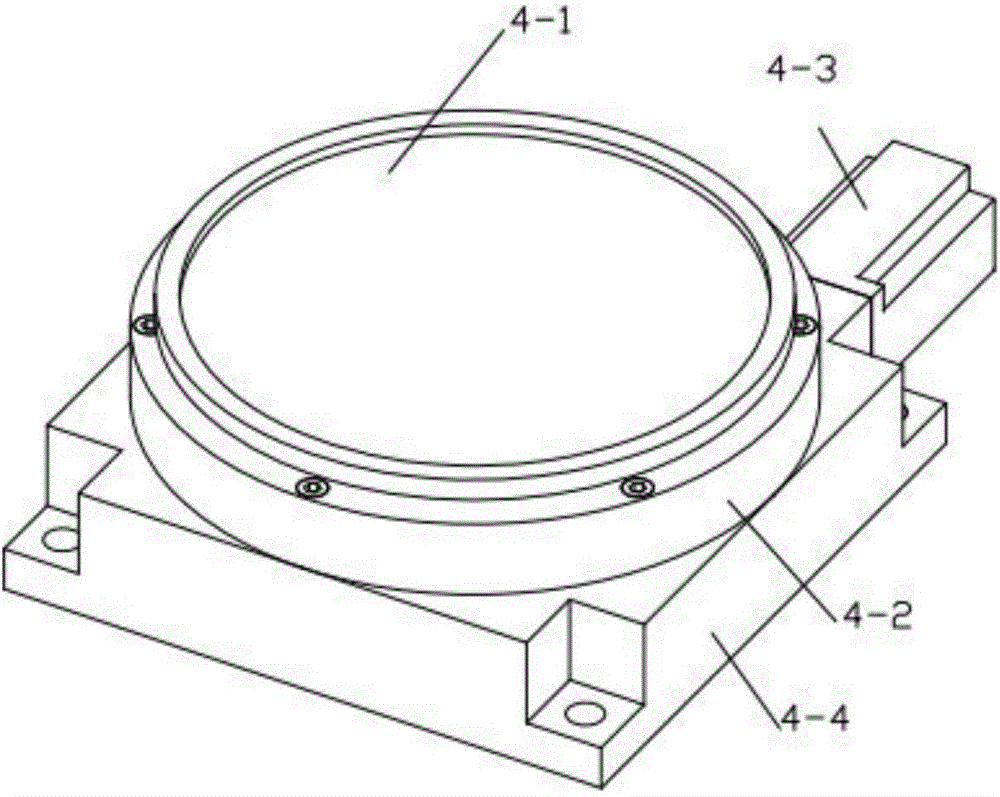

[0025] In the figure, the track-changing-ultrasonic elliptical vibration assisted consolidated abrasive polishing machine includes an ultrasonic generator, a power amplifier, a power part, a polishing part, and a transmission part. The power part drives the transmission part and the polishing part to move, and the power part includes The power source in the directions of X-axis, Y-axis and Z-axis. The power source is preferably a servo motor, which are X-axis servo motor 1, Y-axis servo motor 2, and Z-axis servo motor 3. The polishing part includes a polishing table 4 and a rotary polishing tool. . Main invention points among the present invention: the one, in the chemical mechanical polishing process of consolidated abrasive grain, have introduced ultrasonic elliptical vibration; The technology is the same, so it is not repeated here, and the invention points of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com