Automatic loading/unloading equipment

An automatic loading and unloading and equipment technology, applied in the field of mechanical equipment, can solve the problem of no clamping force adjustment method, and achieve the effect of avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

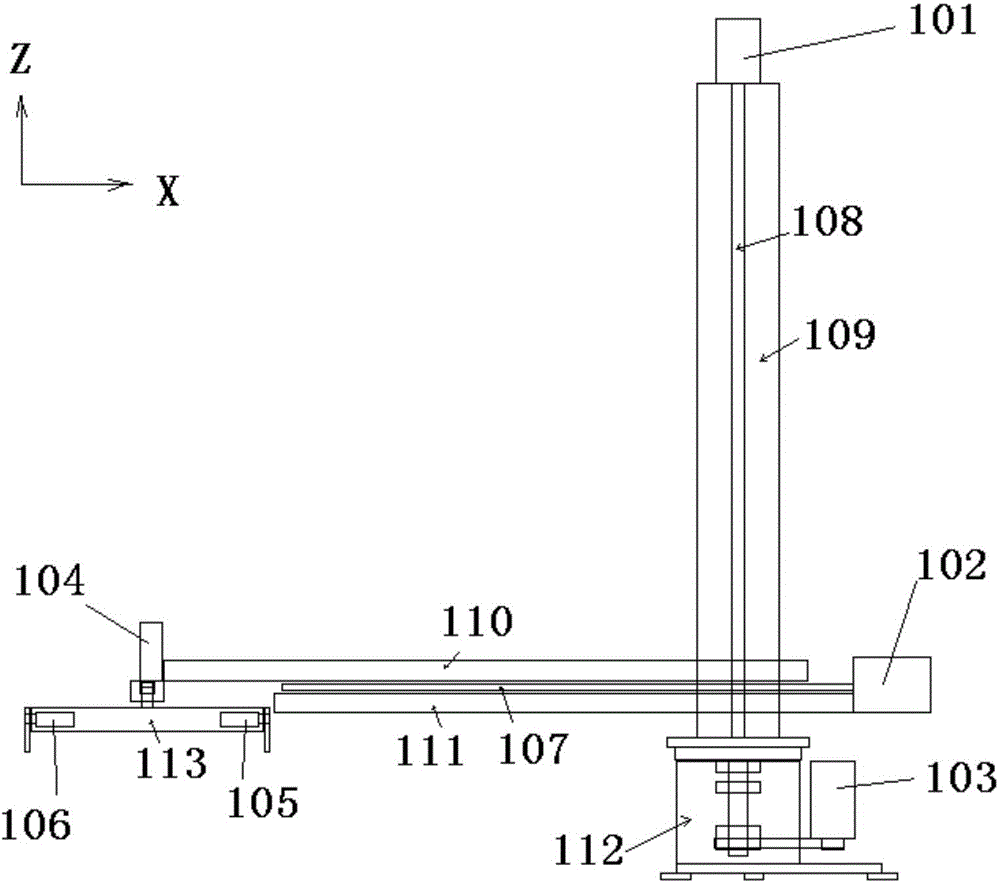

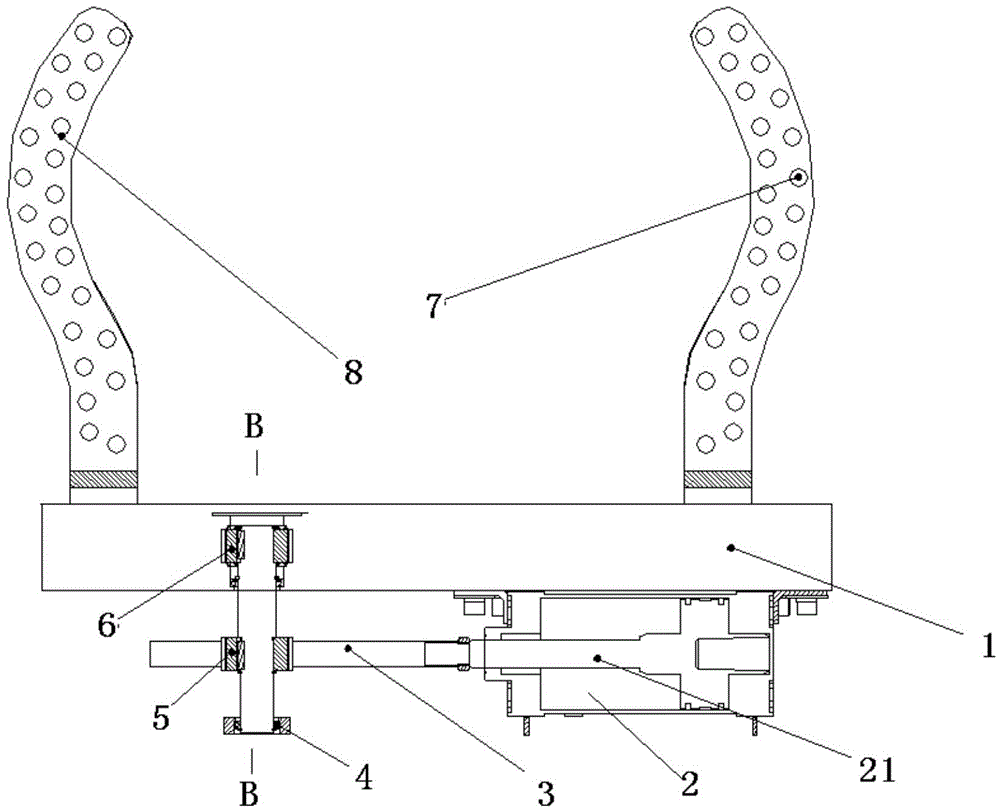

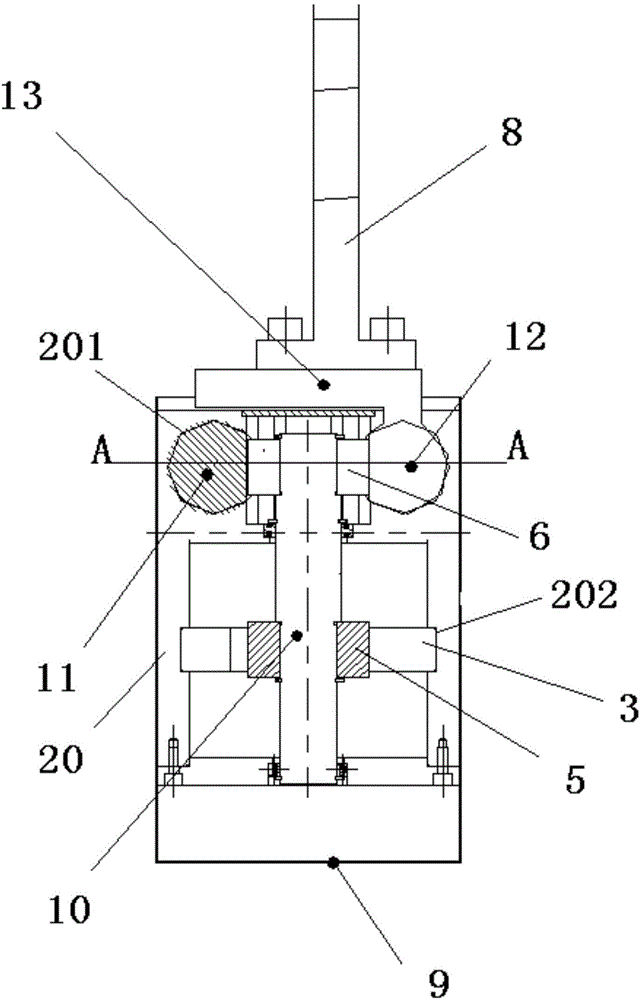

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 As shown, the present invention includes a longitudinal driving device, a horizontal driving device, a rotating device and a clamping part; the clamping part is provided with a material rotating device;

[0022] Described longitudinal driving device comprises the motor one 101 that is arranged on the vertical frame upper end, and described motor one 101 drives lead screw one 108 to rotate, and leading screw one 108 cooperates with the fixed portion of transverse drive device to ensure that transverse drive device can move along the longitudinal frame. 109 move up and down;

[0023] The horizontal driving device includes a motor 2 102, and the motor 2 102 drives a screw 2 107, and the screw 2 107 drives the clamping part to move left and right between the horizontal frames 110 and 111;

[0024] The rotating device includes a motor three 103, and the three motors 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com