Skid wire connection box

A connection box and sliding wire technology, applied in the direction of connection, current collectors, electrical components, etc., can solve the problems of low efficiency, long time consumption of sliding wire connection box, etc., to reduce maintenance cost, reduce maintenance time, installation/removal Fast and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following will further explain and illustrate the sliding wire connection box of the present invention in conjunction with the accompanying drawings and specific embodiments, but such explanations and illustrations do not constitute undue limitations on the technical solution of the present invention.

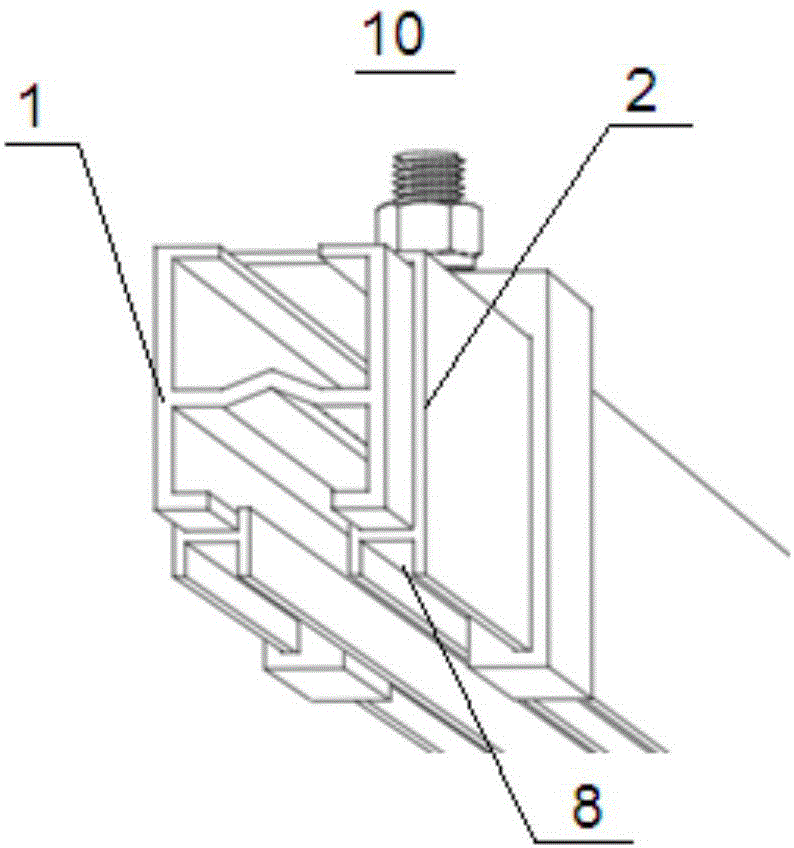

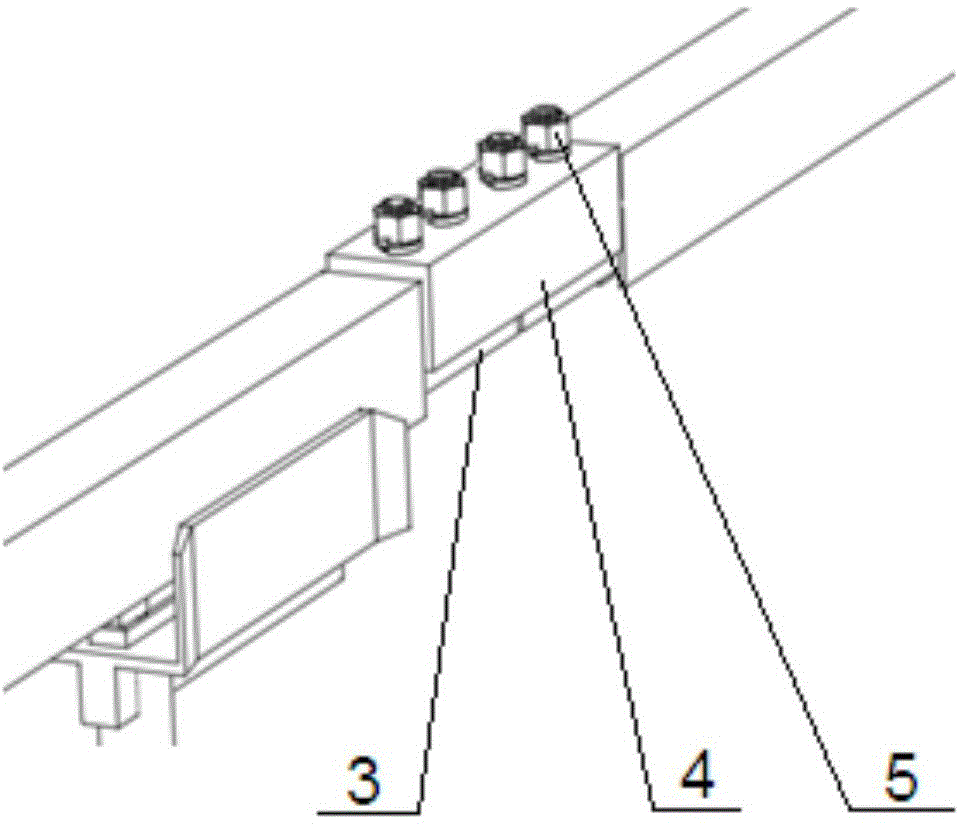

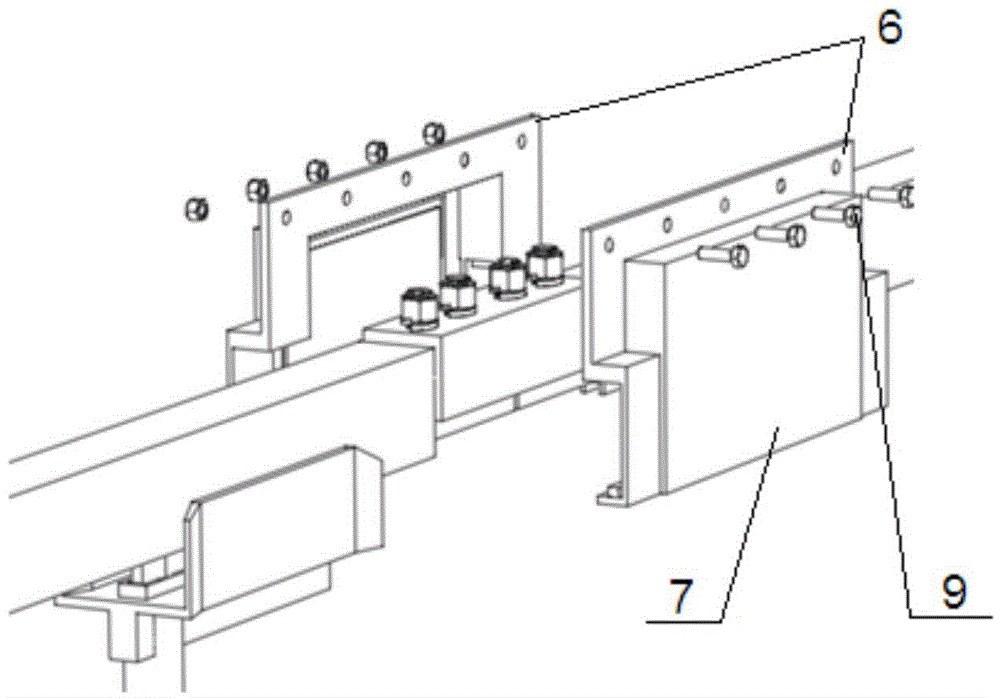

[0037] Figure 4 shows the structure of the sliding wire connection box in an embodiment of the present invention, and Figure 5 then shows Figure 4 The structure of the slider junction box body in the slider junction box shown.

[0038] Such as Figure 4 and Figure 5 As shown, the sliding wire connection box 20 includes two connection box split bodies 21 and two end locking frames 22, and the two connection box split bodies 21 are hingedly connected at one length edge of the two, thereby forming a sliding wire that can be opened and closed. The wire connection box body 25 has a cavity 23 for accommodating the slide wire in the wire connection box, and observat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com