Energy-consuming damping material, and preparation method and application thereof

A technology of damping materials and fillers, which is applied in the field of preparation and energy-consuming anti-seismic materials, can solve the problems of poor replaceability of energy-consuming devices, cumbersome manufacturing processes, and labor and material resources, and achieve prolonging service life, wide sources, and moderate prices. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

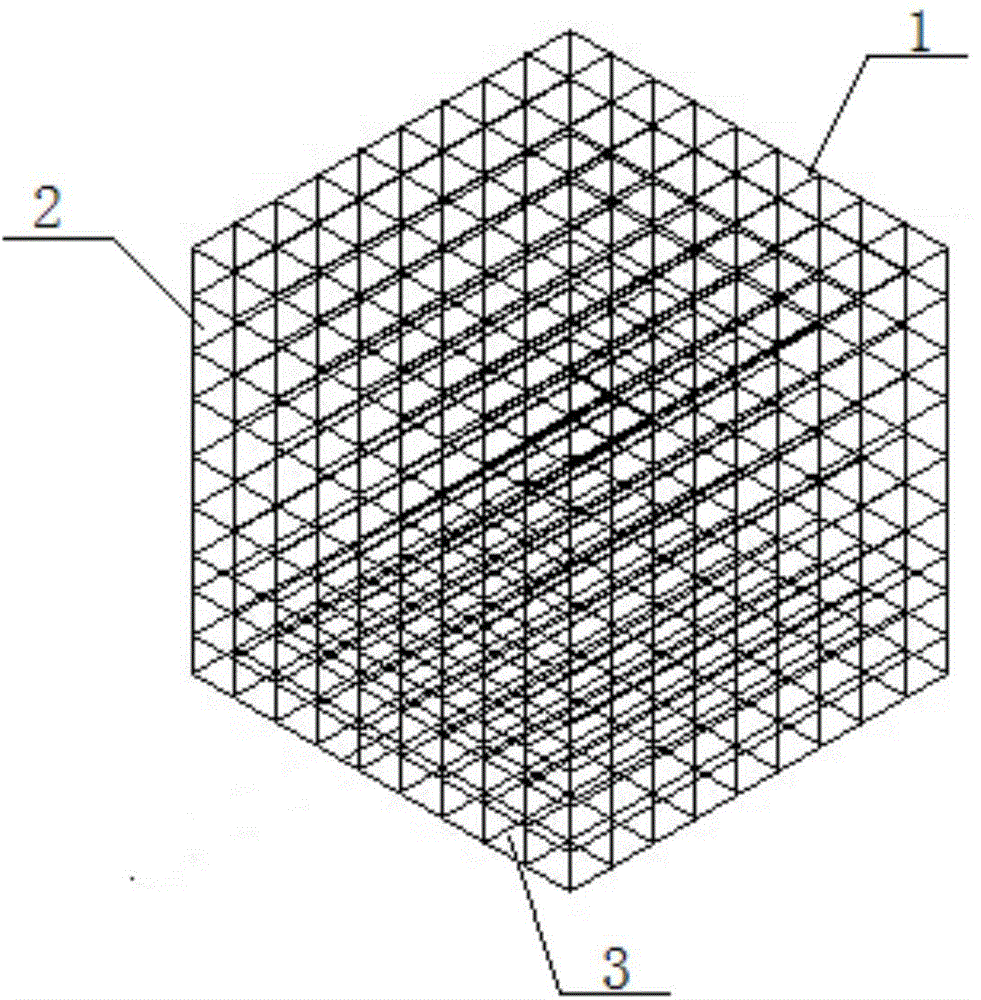

[0024] Such as figure 1 The structural schematic diagram of the energy dissipation damping material shown includes glass fiber filaments 1, fiber mesh 2 and a mixture 3 of epoxy resin and rubber; the energy dissipation damping material is composed of glass fiber filaments 1 arranged perpendicular to each other and filled in glass A one-piece structure composed of filler material 3 inside wire 1.

[0025] There are multiple glass fiber filaments 1, wherein the multiple glass fiber filaments 1 are divided into two groups, the glass fiber filaments 1 in the same group are arranged parallel to each other, and the two groups of glass fiber filaments 1 are arranged perpendicular to each other to form a fiber grid 2, The filler 3 is a mixture 3 of epoxy resin and rubber, which is filled inside the fiber grid 2 .

[0026] The energy dissipation damping material preparation method of the present invention comprises the following steps,

[0027] 1) Prepare the fiber mesh; first, we ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com