Polycarbonate resin/polystyrene resin alloy material and preparation method thereof

A technology of polystyrene resin and polycarbonate resin, applied in the field of polycarbonate resin/polystyrene resin alloy material and its preparation, can solve the problem of reducing the notched impact strength of the material, easy shearing and delamination of pearl powder, etc. problems, achieving obvious effects, improving mechanical properties and impact strength, and good environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

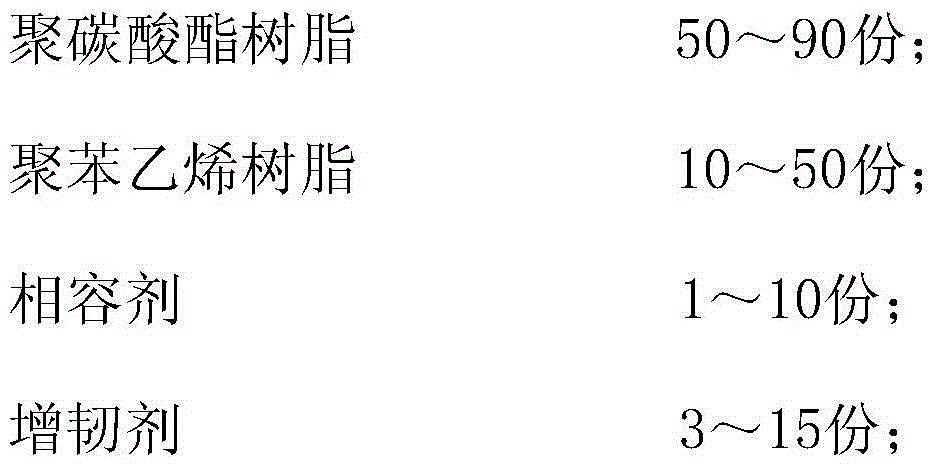

[0030] A polycarbonate resin / polystyrene resin alloy material, the proportion of raw materials is calculated by weight: 50-90 parts of polycarbonate resin; 10-50 parts of polystyrene resin; 1-10 parts of compatibilizer parts; 3-15 parts of toughening agent; 0.2-0.5 parts of pearlescent pigment.

Embodiment 2

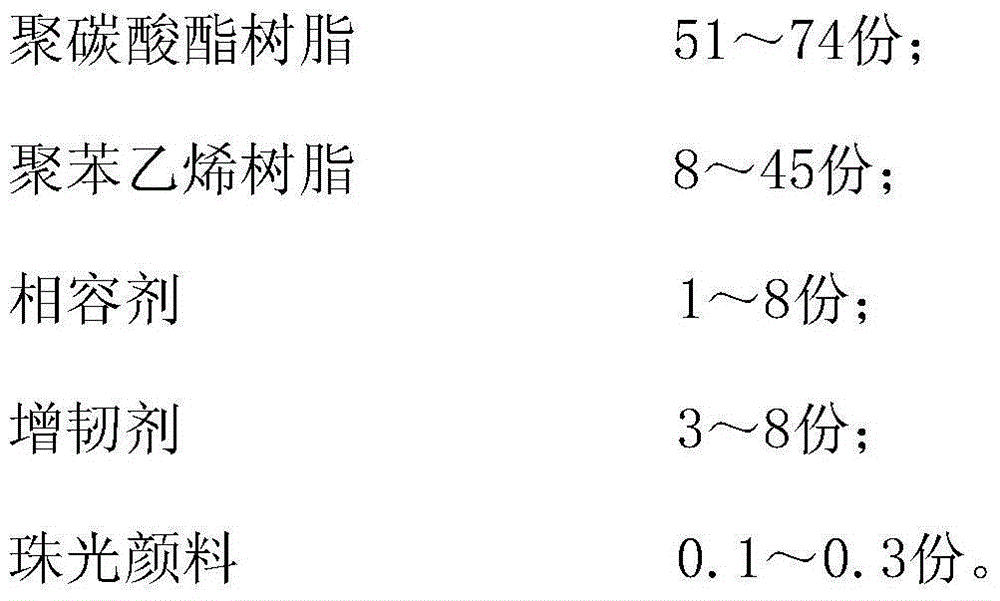

[0032] A polycarbonate resin / polystyrene resin alloy material, the proportion of raw materials is calculated by weight: 51-74 parts of polycarbonate resin; 8-45 parts of polystyrene resin; 1-45 parts of compatibilizer 8 parts; 3-8 parts of toughening agent; 0.1-0.3 parts of pearlescent pigment.

Embodiment 3

[0034] A kind of polycarbonate resin / polystyrene resin alloy material, its raw material ratio is calculated by weight: polycarbonate resin is 60 parts; polystyrene resin is 20 parts; compatibilizer is 6 parts; toughening agent 5 parts; pearlescent pigment is 0.2 parts.

[0035] The compatibilizer can be an epoxy polymer resin, specifically a terpolymer random copolymer of styrene-acrylonitrile-glycidyl methacrylate, and the addition amount is 3-5%, taking into account the rigidity and Toughness, does not affect the processing performance of the material; the epoxy group (GMA) content of the side chain pendant is 0.8-6.0%, which has a very high chemical reactivity; it can also be used as a chain extender and heat stabilizer.

[0036] The toughening agent can be an MBS impact modifier, specifically a methyl methacrylate-butadiene-styrene terpolymer, and the weight percentage of methyl acrylate is 5-45%. The weight percentage of diene is 10-40%, and the weight percentage of styr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap