Spaced formwork supporting and concrete pouring method for pitched roof

A technology for concrete and sloping roofs, applied to roofs, buildings, building components, etc., can solve the problems of inconvenient vibration, inconvenient, local honeycomb in concrete, etc., and achieve the effect of novel method and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Sloping roof spacing formwork and concrete pouring method of the present invention is characterized in that comprising the following steps:

[0039] a. Lay out the line on the bottom formwork of the sloping roof

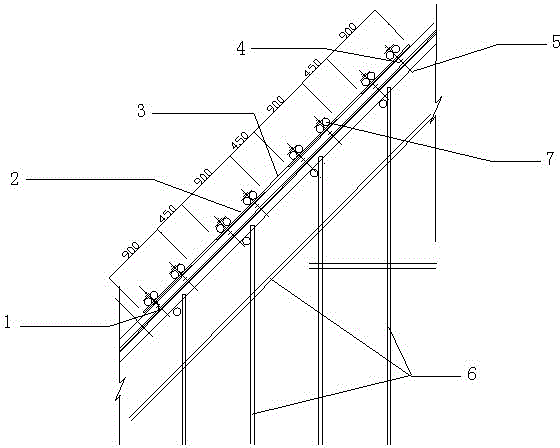

[0040] see now figure 1 , figure 1 It is a schematic diagram of the formwork of the embodiment of the present invention. According to the conventional method, after installing the bottom formwork of the sloping roof, set out the wires according to the form and size of the sloping roof, set up the formwork according to the 900mm interval size, and set a 450mm space; set the support system shelf 6 under the bottom formwork of the sloping roof;

[0041] b. Install the reinforced horse stool

[0042] After laying the steel bars on the roof, install the steel bar stool 1 with a spacing of 450mm according to the interval setting position; the height of the steel bar stool is the same as the thickness of the board to ensure the thickness of the board;

[0043] c....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com