Steel stair formwork and constructing method for once pouring forming of building staircase

A technology for stairwells and stairs, which is applied to the processing of building materials, formwork/formwork/work frames, and preparation of building components on site, which can solve the problem of increasing construction complexity and construction costs, and the inability of wooden step templates Problems such as repeated use and affecting the flatness of the wall in the stairwell can be avoided to avoid secondary pre-embedded steel bars, shorten the construction period, and improve the construction safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] The invention is applicable to the construction of all reinforced concrete stairwells, especially to the construction of standard floors.

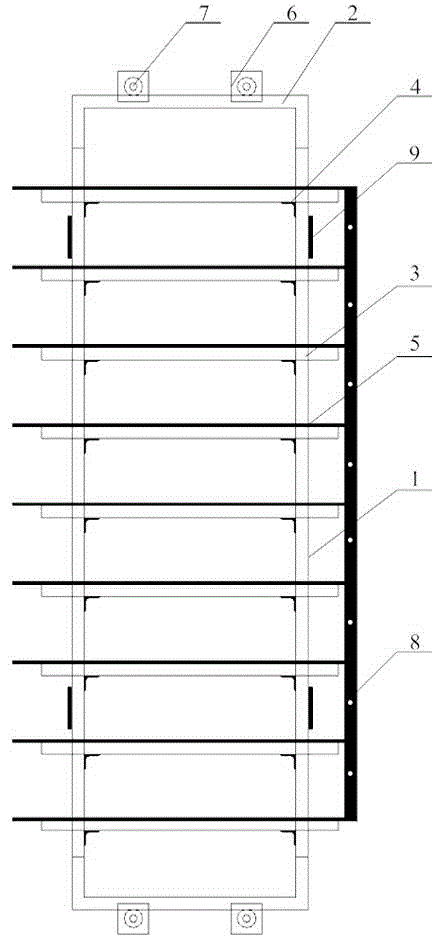

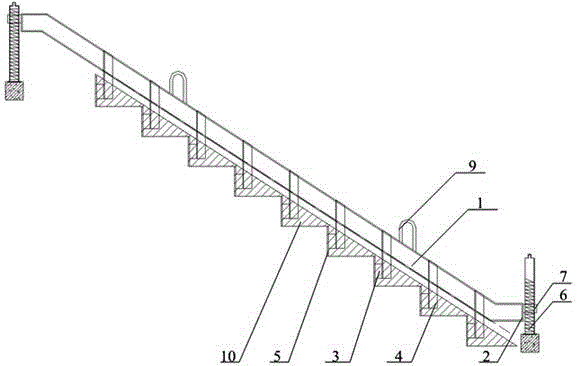

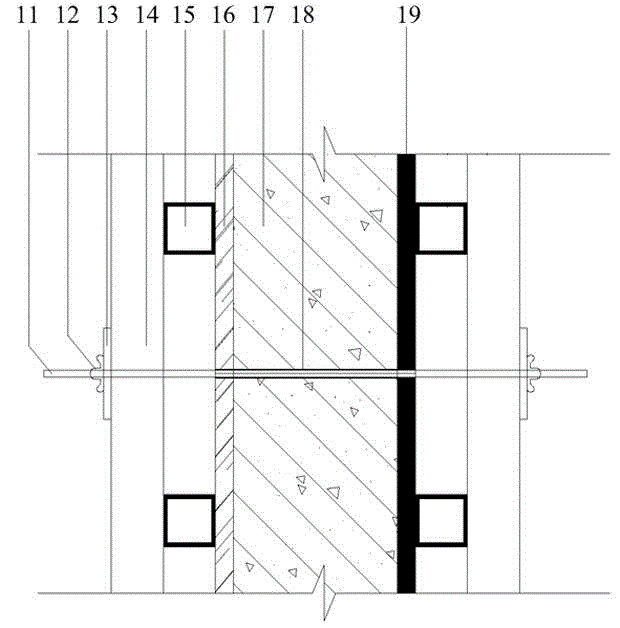

[0020] like figure 1 and 2 As shown, the steel stair formwork of the present invention includes two inclined beams 1 that can be erected between the upper and lower staircase turntables of the adjacent floors. The two inclined beams 1 are arranged in parallel and at intervals. The spaces are respectively connected and fixed by two beams 2, and the two beams 2 are parallel to each other to form a rectangular formwork. The outer sides of the two beams 2 (ie, the two ends of the formwork) are respectively fixed with two nuts 6, and the two nuts 6 are arranged at intervals, and each nut 6 is screwed into an adjusting screw 7 to support the formwork, and the adjusting screw is rotated. Bar 7 can adjust the height of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com