Novel super-energy-saving gas turbine

A gas turbine, ultra-energy-saving technology, applied in the direction of gas turbine devices, mechanical equipment, machines/engines, etc., can solve the problems of wasting internal energy, energy waste, waste of heat, etc., and achieve the effect of easy understanding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

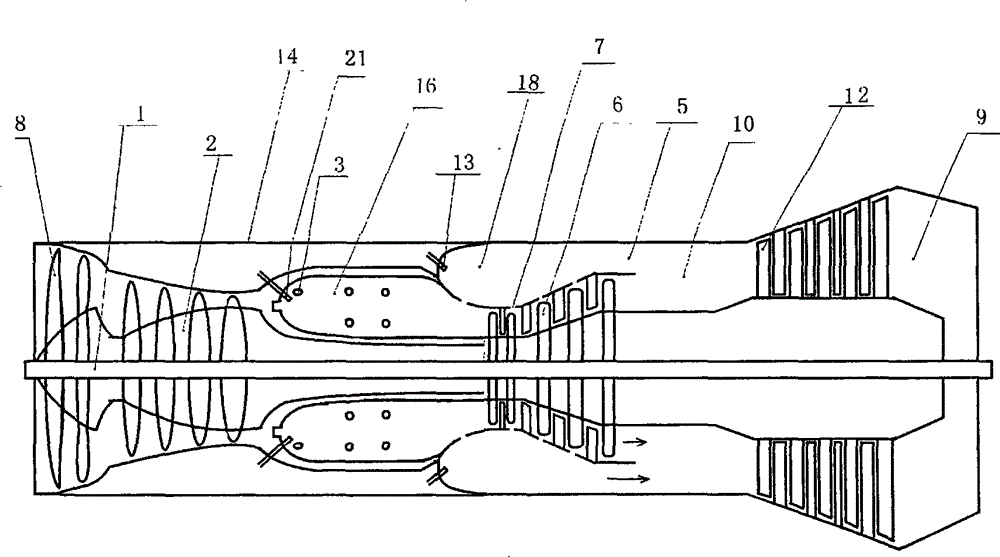

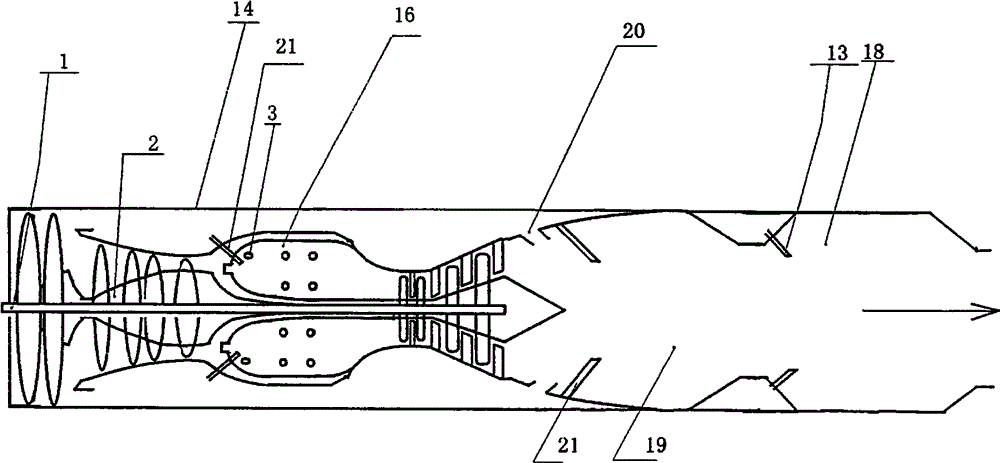

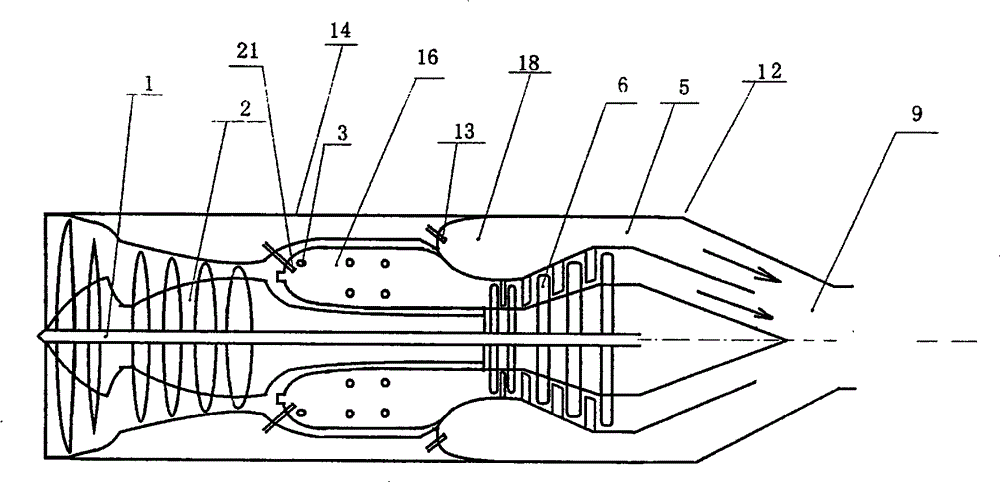

[0020] When the starter motor drives the main shaft to rotate, the air supercharger rotates to work, high-pressure air enters the combustion cylinder, fuel is injected into the nozzle, the two gases are mixed to produce a mixed gas, the igniter is ignited, and the fuel in the combustion chamber burns violently, resulting in a shock Part of the airflow directly impacts the impeller to rotate, and the other part of the airflow enters the steam cylinder with heat impact to heat the steam to generate ultra-high temperature super-power steam and then pushes the impeller to rotate, or the gas of the two cylinders is mixed and heated in the steam and gas mixing chamber to produce Super-powerful steam, again pushing the machine to spin, or again pushing the plane forward at a higher speed. The steam turbine of the present invention is mainly derived from the steam cylinder that produces a particularly huge steam power impact that is 60-100 times larger than that of a traditional gas tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com