Flexible cable fixing device

A technology of fixing device and flexible cable, applied in the direction of pipe support, pipe/pipe joint/pipe fitting, mechanical equipment, etc., can solve the problem of material waste and achieve the effect of flexible fixing, strong practicability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

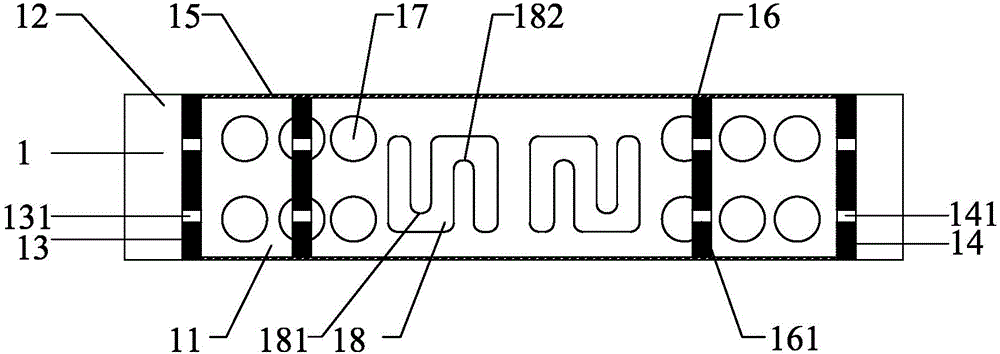

[0019] Such as figure 1 As shown, a flexible cable fixing device includes a flexible fixing frame main body 1, and the flexible fixing frame main body 1 includes a flexible bottom plate 11 and is fixed at both ends of the flexible bottom plate 11 to form an open rectangular frame with the flexible bottom plate 11. The edge 12 of the flexible bottom plate 11 is provided with a circular through-hole 17 for the cable to pass through and an S-shaped through-hole 18 for the cable to pass through and clamp the cable. The bending of the S-shaped through-hole 18 There is a first rounded corner 181 and a second rounded corner 182;

[0020] Both ends of the flexible bottom plate 11 near the edge 12 are respectively provided with a first fixed baffle 13 and a second fixed baffle 14, and the first fixed baffle 13 is provided with at least two first fixed holes 131, The second fixed baffle 14 is provided with at least two second fixing holes 141; the flexible base 11 between the first fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com