Horizontal coil pipe

A coil, horizontal technology, applied in the field of horizontal coils, can solve the problems of fan coil installation, troublesome assembly, poor flexibility, etc., achieve the effect of simple process and structure, reduce production cost, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention will be described in detail below with reference to the drawings, but the invention is not limited to the following examples.

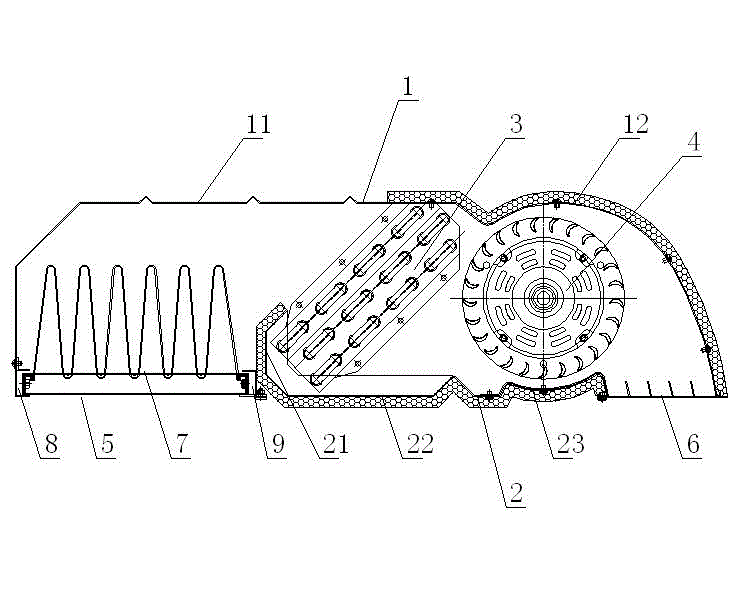

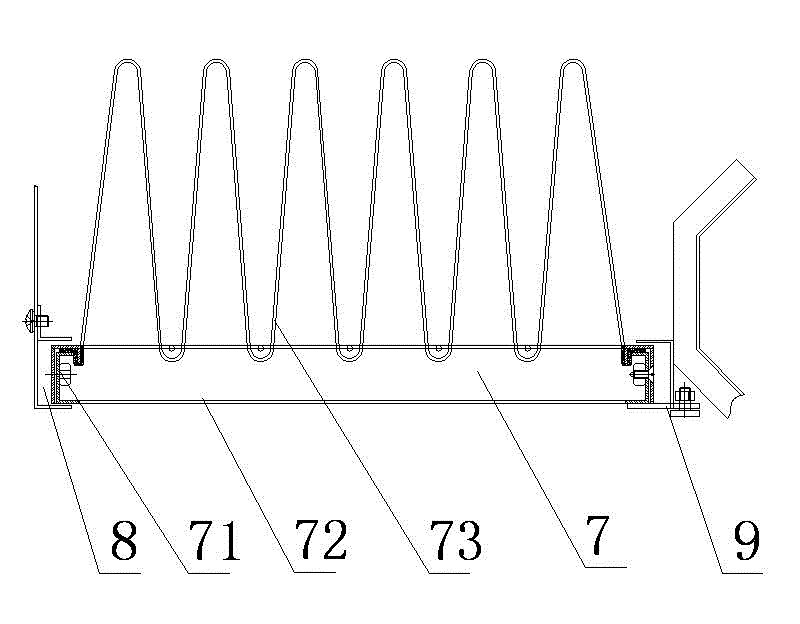

[0019] Such as figure 1 As shown, a horizontal coil includes an upper shell 1 , a lower shell 2 , a coil assembly 3 , a fan 4 , an air inlet 5 , and an air outlet 6 . The upper shell 1 and the lower shell 2 are formed by integral stamping or integral injection molding, and the shell material is a thin metal plate or a plastic plate. The upper shell 1 and the lower shell 2 are connected to each other by inlaying or screwing, riveting, or gluing, so as to facilitate assembly and disassembly. The overall molding process and mosaic connection can effectively reduce parts, shorten the production cycle, save raw materials, significantly reduce production costs and improve production efficiency.

[0020] The present invention is different from the design of the existing fan coil 4. The upper shell 1 is composed of a box body section 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com