Noise isolation device for power equipment

A technology for noise isolation and power equipment, applied in the direction of sound-producing equipment, active noise control, instruments, etc., can solve problems such as installation trouble, achieve the effect of convenient installation, convenient connection, and solve the trouble of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

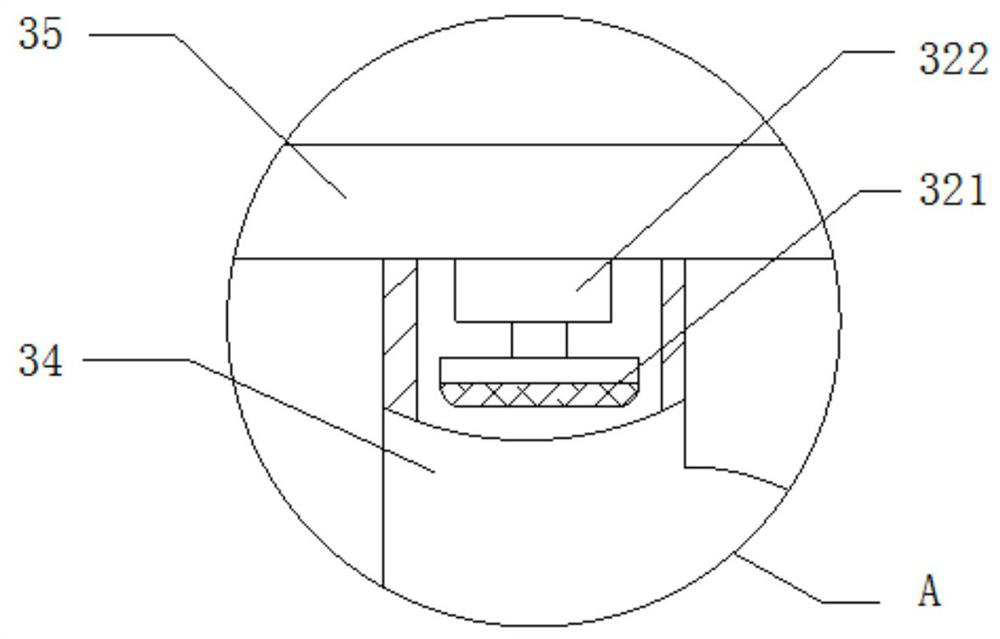

[0041] This embodiment is an embodiment of the noise isolation mechanism in the first embodiment.

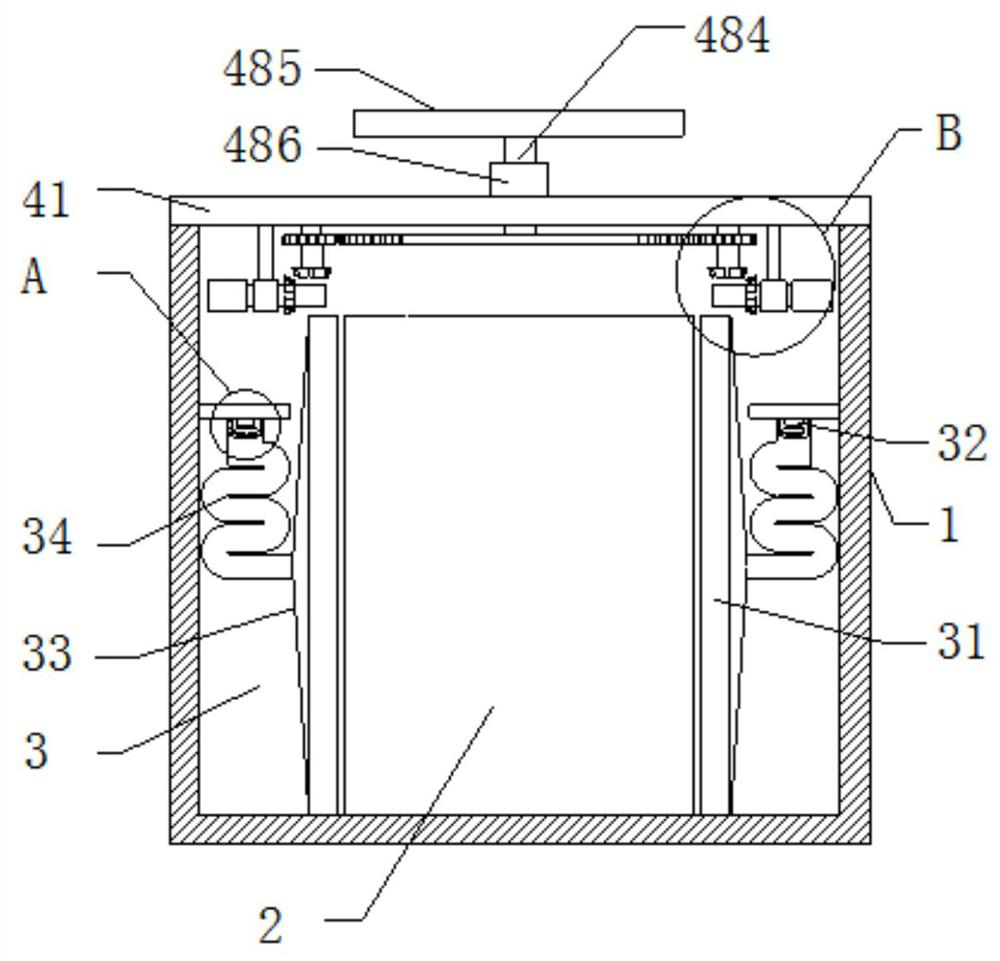

[0042] A key structure for a noise isolation device for power equipment, which is a noise isolation mechanism, including a honeycomb panel 31, the side of the honeycomb panel 31 away from the power equipment 2 is fixedly connected to a sound guide bucket 33, and the other end of the sound guide bucket 33 is fixedly connected There is a U-shaped tube 34, and the other end of the U-shaped tube 34 is fixedly connected with a noise reduction plate 35, and the side of the noise reduction plate 35 close to the U-shaped tube 34 is fixedly installed with a noise reduction module 32, and the noise reduction module 32 includes a noise reduction microphone 321 A calculation module 322 is fixedly connected to a side of the noise reduction microphone 321 close to the noise reduction board 35 , and the calculation module 322 is fixedly connected to the noise reduction board 35 .

[0043] The ...

Embodiment 3

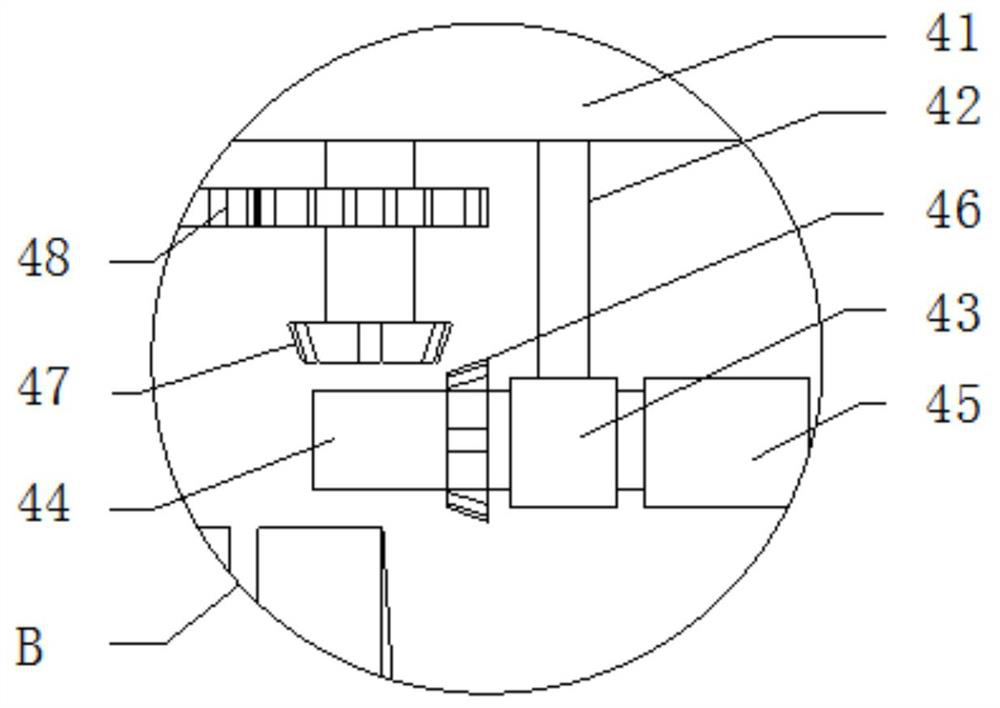

[0045] This embodiment is an embodiment of the installation mechanism in the first embodiment.

[0046] A key structure for a noise isolation device for power equipment, which is an installation mechanism, including an installation top plate 41, and both sides of the bottom end of the installation top plate 41 are fixedly installed with installation columns 42, and the other end of the installation column 42 is fixedly connected with an installation sleeve 43 , the middle part of the mounting sleeve 43 is clamped with a threaded column 44, and one end of the threaded column 44 is threadedly connected to the limit column 45, and the outer surface of the other end of the threaded column 44 is fixedly installed with a driven bevel gear 46, and the top of the driven bevel gear 46 is driven. Connected with driving bevel gear 47, the top of driving bevel gear 47 is fixedly connected with adjusting mechanism 48, and adjusting mechanism 48 comprises synchronous column 481, and the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com