Heat dissipation substrate

A technology of heat dissipation substrate and heat dissipation block, which is applied in heat transfer modification, heat exchange equipment, indirect heat exchanger, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

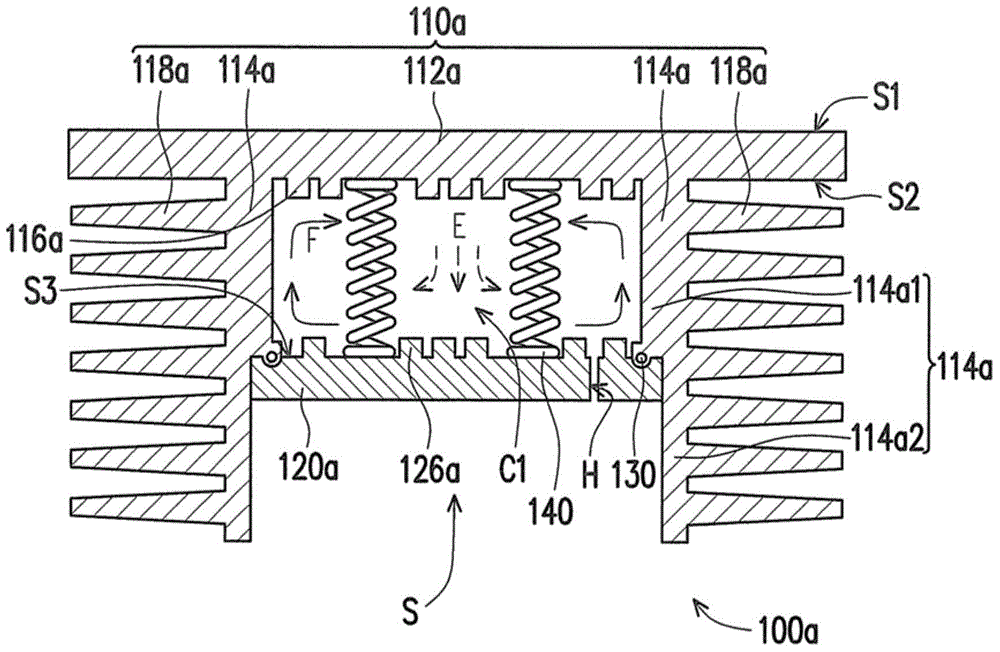

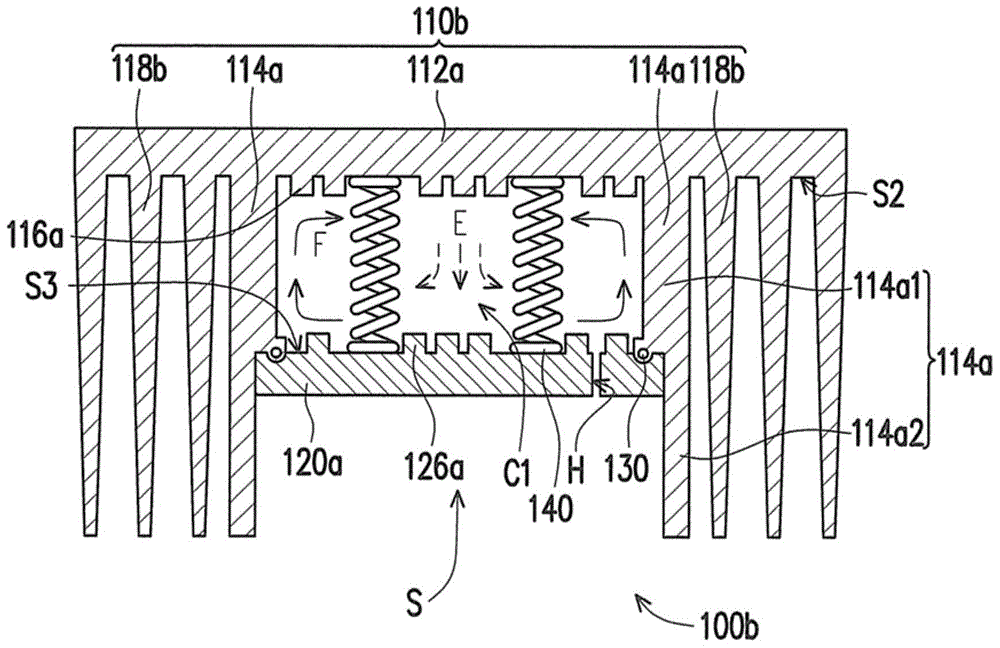

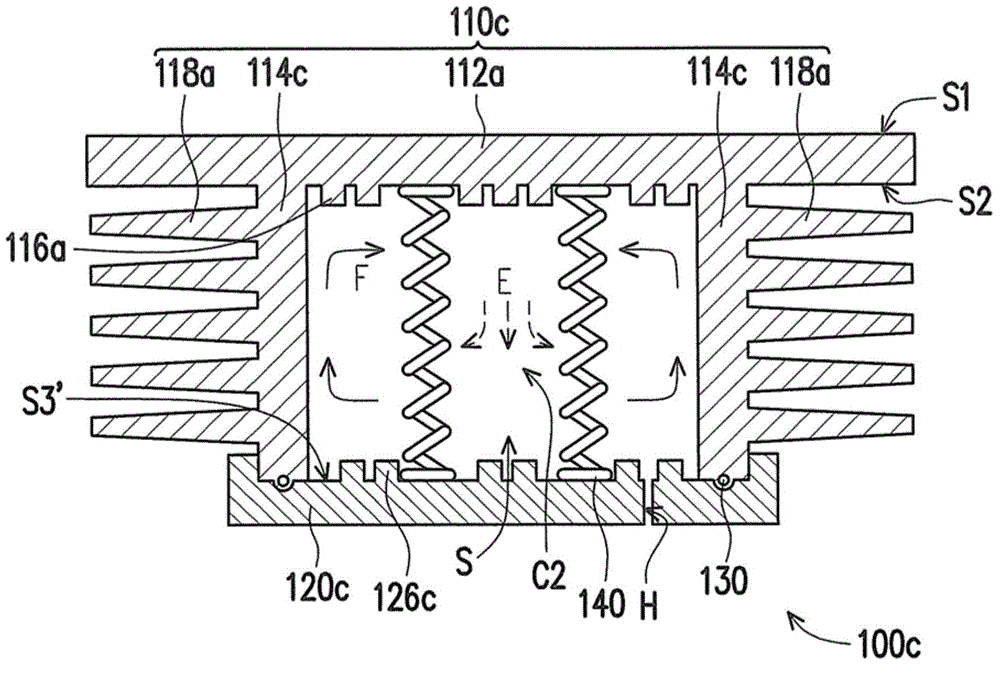

[0051] figure 1 A schematic cross-sectional view of a heat dissipation substrate according to an embodiment of the present invention is shown. Please refer to figure 1 , in this embodiment, the heat dissipation substrate 100a includes a heat dissipation block 110a, a metal substrate 120a and at least one elastic structure 140 ( figure 1 Two are schematically shown in ). The heat dissipation block 110a includes a carrying portion 112a and a plurality of supporting portions 114a. The carrying portion 112a has a carrying surface S1 and a lower surface S2 facing each other. The supporting portions 114a are parallel to each other and disposed on the lower surface S2 of the bearing portion 112a. The support portions 114a are vertical to the carrying portion 112a and surround the carrying portion 112a to form an accommodating space S. Referring to FIG. The carrying portion 112a has a first rough surface structure 116a on a portion of the lower surface S2, and the first rough sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com