Piezoelectric type six-dimensional force/torque sensor adopting six groups of force-measuring sensitive units

A technology of torque sensor and sensitive unit, which is applied in the field of piezoelectric six-dimensional force/torque sensor, can solve the problems of difficult decoupling, high manufacturing process requirements, and many force measurement sensitive units, so as to achieve simple mechanical model and reduce manufacturing cost , the effect of reducing the difficulty of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

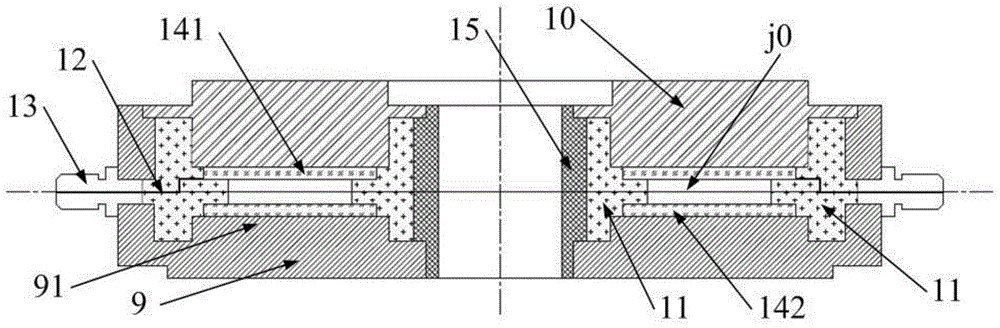

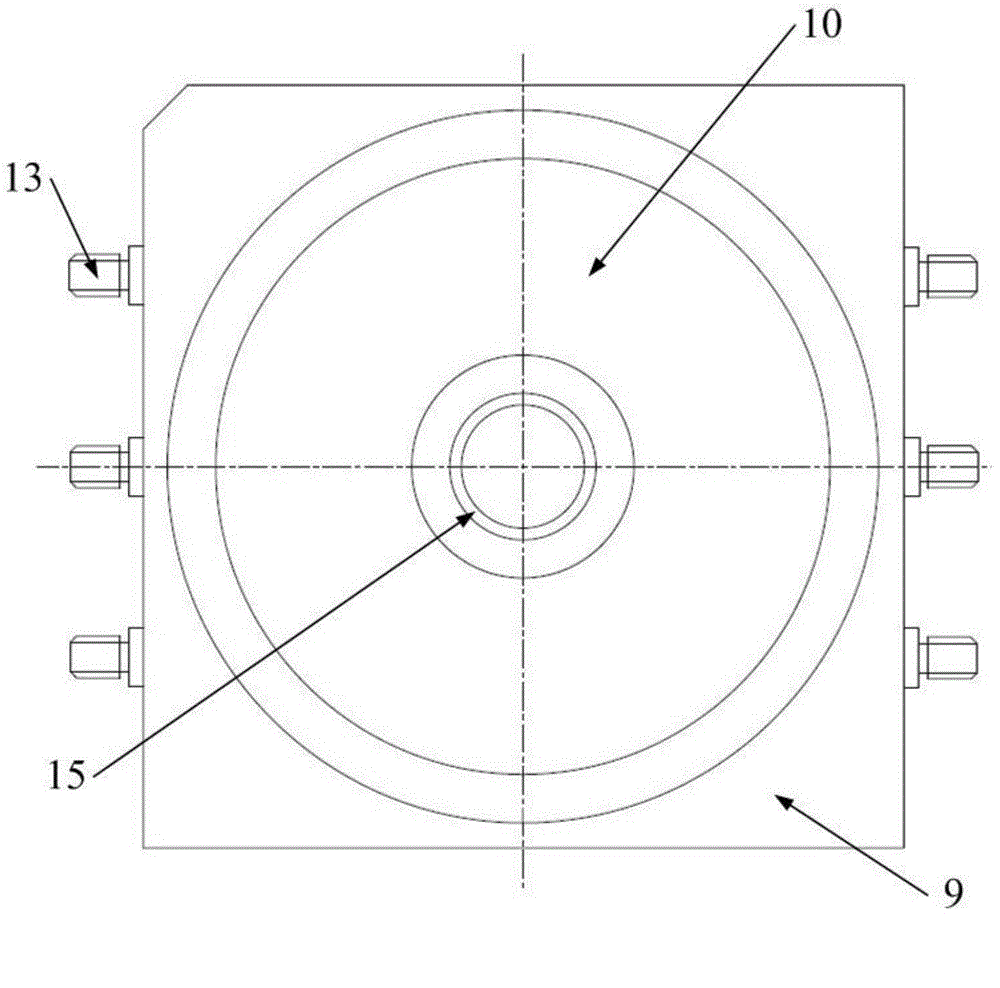

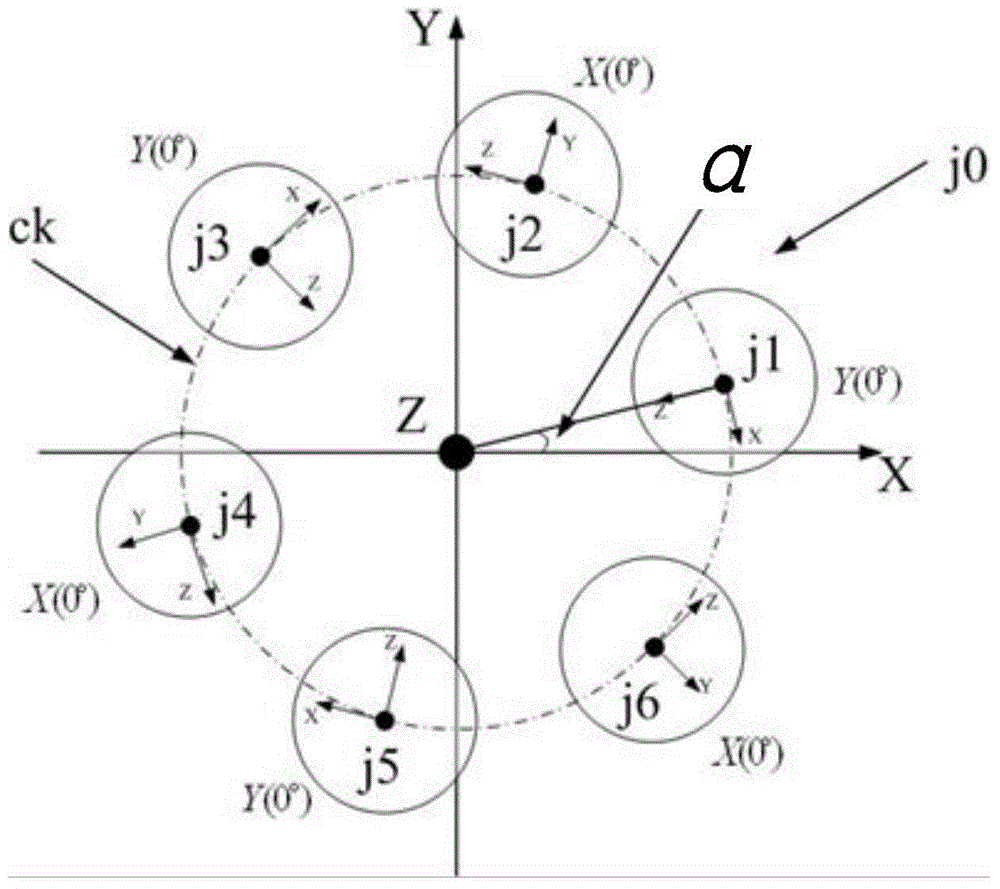

[0012] Piezoelectric six-dimensional force / torque sensor with 6 sets of force-measuring sensitive units (refer to figure 1 , 2 , 3, 4), including a base 9 with a mounting plate 91 inside and an output electrode socket 13 outside, the force-measuring sensitive unit j0 installed on the internal mounting plate 91 of the base 9 clamps the force-measuring sensitive Two upper and lower insulating electrode plates 141, 142 of the unit j0; the upper cover 10 tightly pressed on the upper insulating electrode plate 141, connects the electrodes on the two insulating electrode plates 141, 142 and the output electrode socket 13 on the base 9 The signal lead-out wire 12 is used to fix and insulate the insulation filling material 11 of the signal lead-out wire 12, and the inner sealing sleeve 15 of the two is connected at the inner hole of the upper cover 10 and the base 9; wherein, the force measuring Sensitive unit j0 is made of several quartz wafers, and these quartz wafers are evenly di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com