Eddy radar defect detecting, quantifying and imaging method and system

A defect detection and imaging method technology, applied in the fields of material characterization and evaluation, equipment non-destructive testing, structural health monitoring and product quality control, which can solve problems such as poor anti-interference, low signal-to-noise ratio, and difficulty in judging distances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The specific embodiments of the present invention are described below with reference to the accompanying drawings, so that those skilled in the art can better understand the present invention.

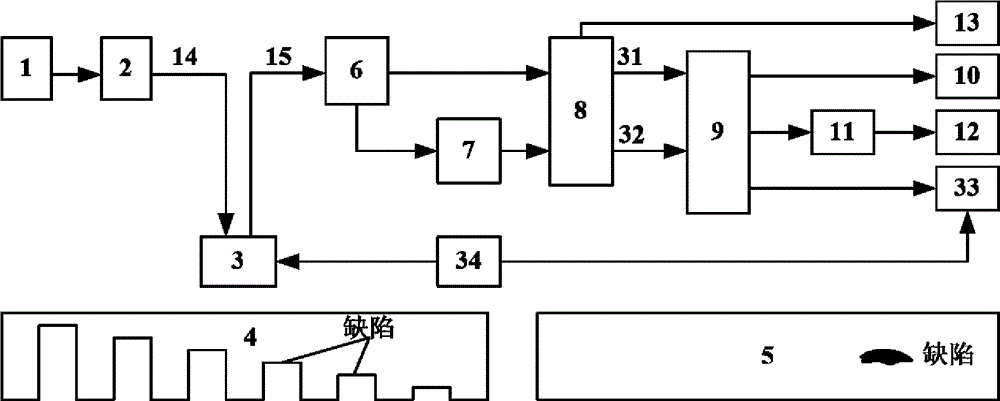

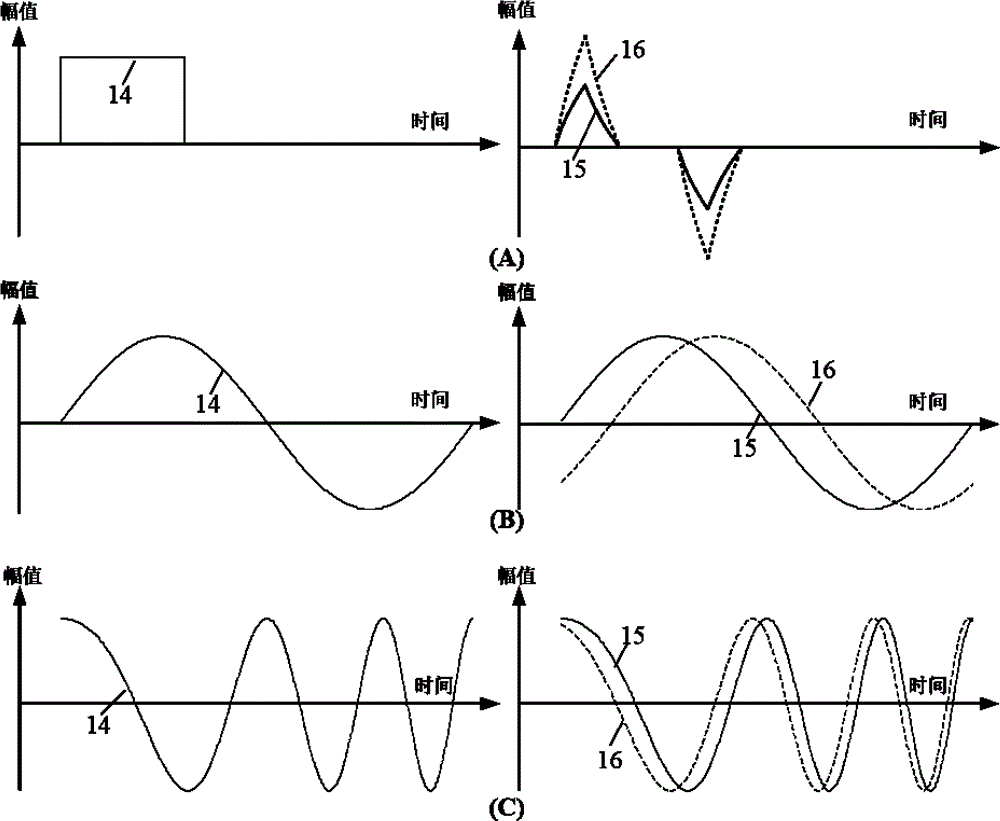

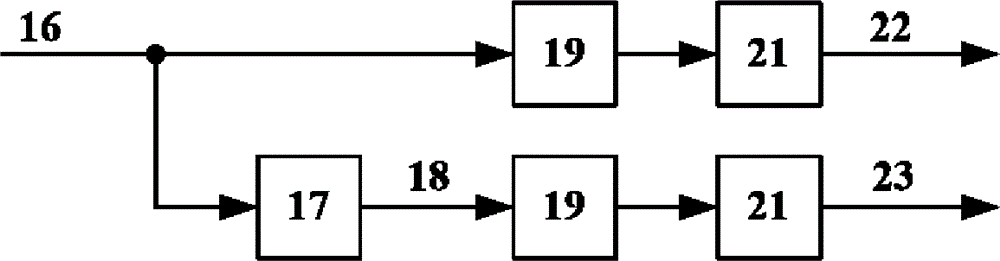

[0057] figure 1 It is a schematic diagram of an eddy current radar defect detection, quantification and imaging system, which mainly includes: human-machine interface 1, excitation signal module 2, eddy current sensor 3, standard specimen 4, tested object 5, signal conditioning module 6, reference signal setting Module 7 , signal processing module 8 , feature value extraction module 9 , defect detection module 10 , quantitative relationship determination module 11 , defect quantitative module 12 , B-scan imaging module 13 , C-scan imaging module 33 , and scanning mechanism 34 .

[0058] The specific implementation steps of an eddy current radar defect detection, quantification and imaging method based on an eddy current radar defect detection, quantification and imaging system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com