A method and equipment for rapid prototyping design of pwm controller realized by general industrial computer combined with dsp

An industrial computer and controller technology, applied in the directions of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of high real-time requirements for code running, a single chip cannot meet the real-time requirements of computing, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

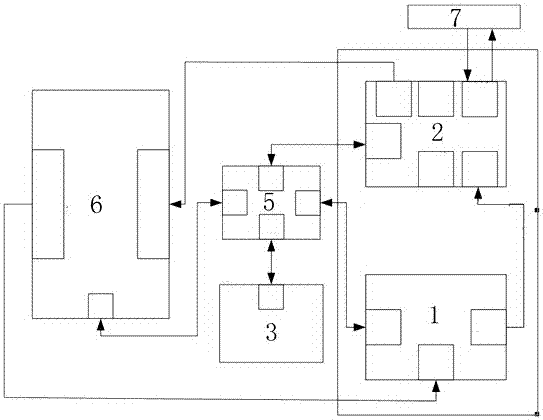

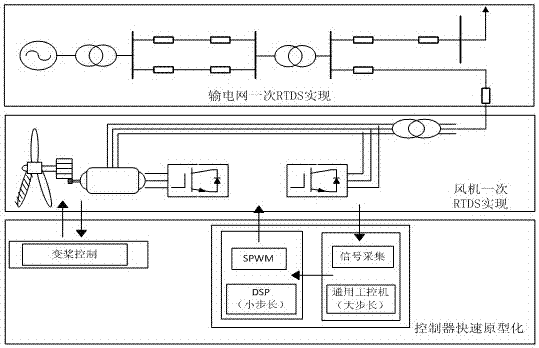

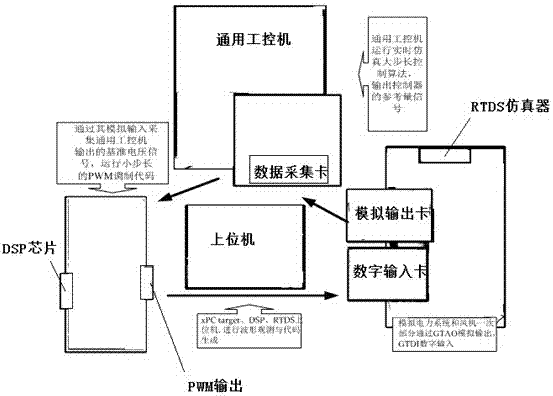

[0016] Embodiment 1 of the present invention: a general industrial computer combined controller realizes a rapid prototyping method of a PWM controller, figure 2 It is a structural diagram of an embodiment of the present invention. It can be seen from the figure that this embodiment is a rapid prototyping design of a double-fed fan converter controller. The power transmission and distribution primary system and the primary part of the double-fed fan equipment are simulated by RTDS to simulate the power system Primary and secondary equipment characteristics, set various power system faults, the secondary part of the fan equipment (power electronic converter controller) is quickly prototyped by the general industrial computer combined controller (DSP); run large-step control on the general industrial computer Algorithm, run the small step size control algorithm on the DSP, which can effectively solve the requirements of real-time simulation calculation accuracy and calculation v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com