Slurry-resistant oil-resistant power cable for oil platform

A mud-resistant and oil-resistant power cable technology, which is applied in the direction of power cables with shielding layers/conductive layers, insulated cables, cables, etc., can solve the problems that cannot meet the mud resistance, oil resistance and flame retardancy of cables at the same time, Achieve the effects of enhancing flame retardancy, optimizing cable structure, and satisfying mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing of description and embodiment:

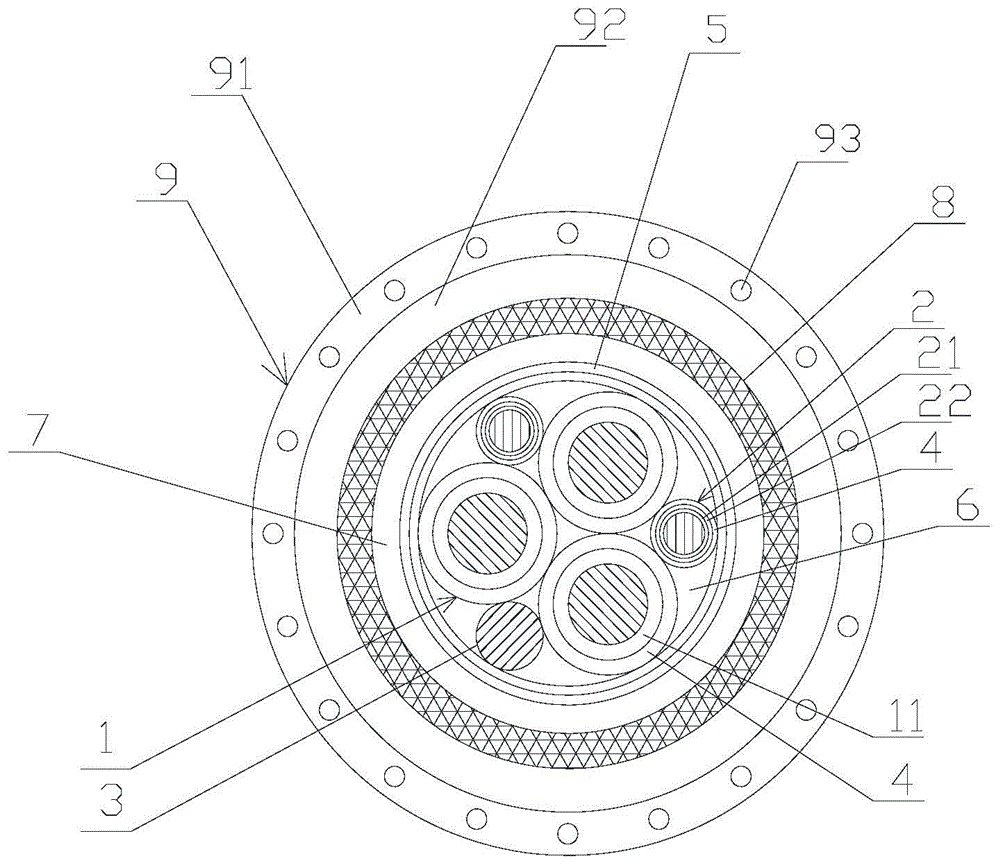

[0010] As shown in the figure, the inner core of the mud-resistant and oil-resistant power cable for oil platforms is twisted by three power conductors 1, two communication conductors 2 and a filling rope 3 made of glass fiber; the conductor of the power conductor is the connection Tin-plated copper wire is drawn and stripped, and its exterior is an electric insulation layer 11 made of ethylene-propylene rubber, and the exterior of the electric insulation layer is wrapped with an aluminum foil layer 4; the outside of the conductor of the communication wire 2 is a communication insulation layer 21 made of ethylene-propylene rubber , the outside of the communication insulation layer is wrapped with a braided shielding layer 22, and the outside of the braided shielding layer has an aluminum foil layer 4; the three power wires are evenly distributed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap