Improved non-contact transformer with secondary side current phase detection function

A technology of phase detection and secondary current, applied in the direction of measuring current/voltage, transformer/inductor core, transformer/inductor coil/winding/connection, etc., can solve the problem of system size reduction, reduce coupling coefficient, Simplify the circuit structure and reduce the effect of interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

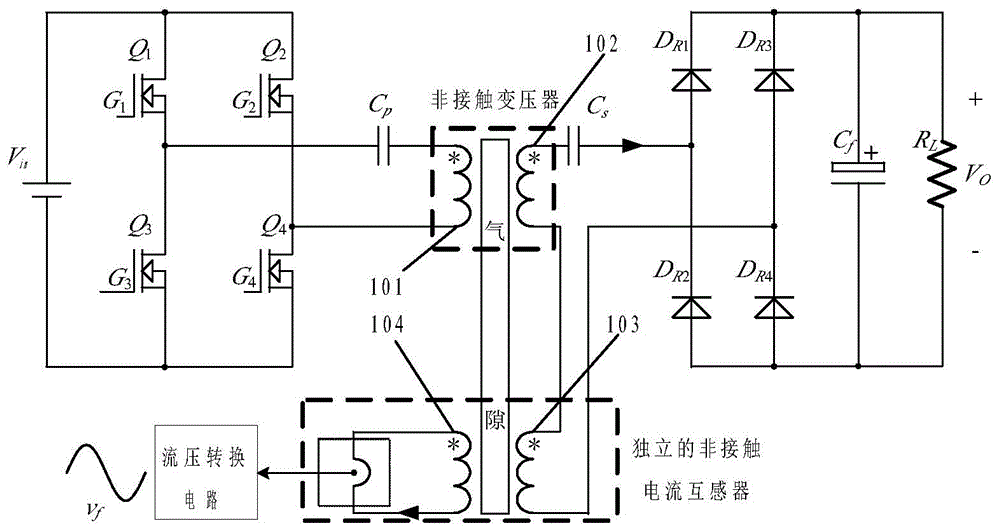

[0050] attached Picture 1-1 A full-bridge application circuit of an existing non-contact transformer plus an independent non-contact current transformer is given, wherein 101 is the primary side of the non-contact transformer, 102 is the secondary side of the non-contact transformer, and 103 is the excitation side of the non-contact current transformer. 104 is the test side of the non-contact current transformer, and 103 and 104 constitute an independent non-contact current transformer.

Embodiment 2

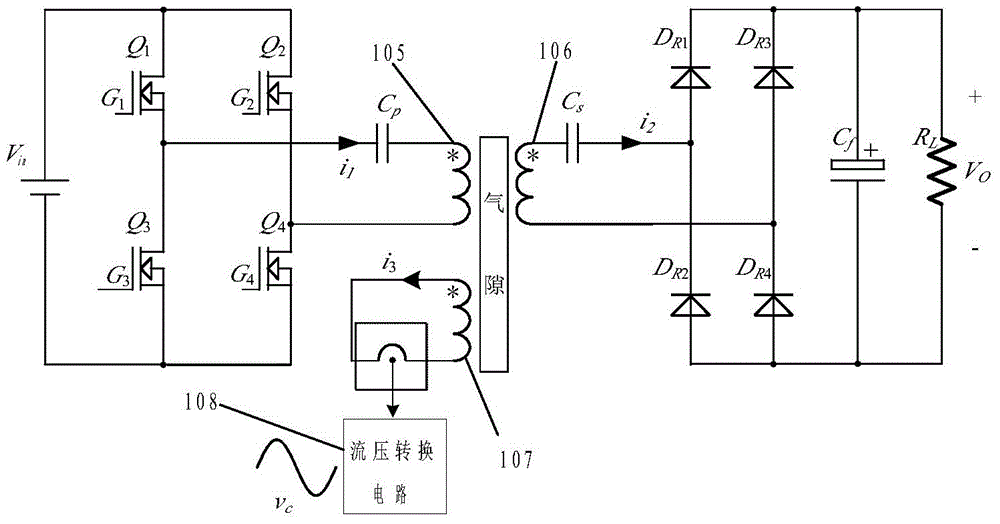

[0052] attached Figure 1-2 The full-bridge application circuit of the improved non-contact transformer of the present invention is given, compared Picture 1-1 with Figure 1-2 It can be seen that the improved non-contact transformer will not change the topology of the main circuit, where 105 is the primary winding, 106 is the secondary winding, 107 is the test winding, and 108 is the current-voltage conversion circuit.

Embodiment 3

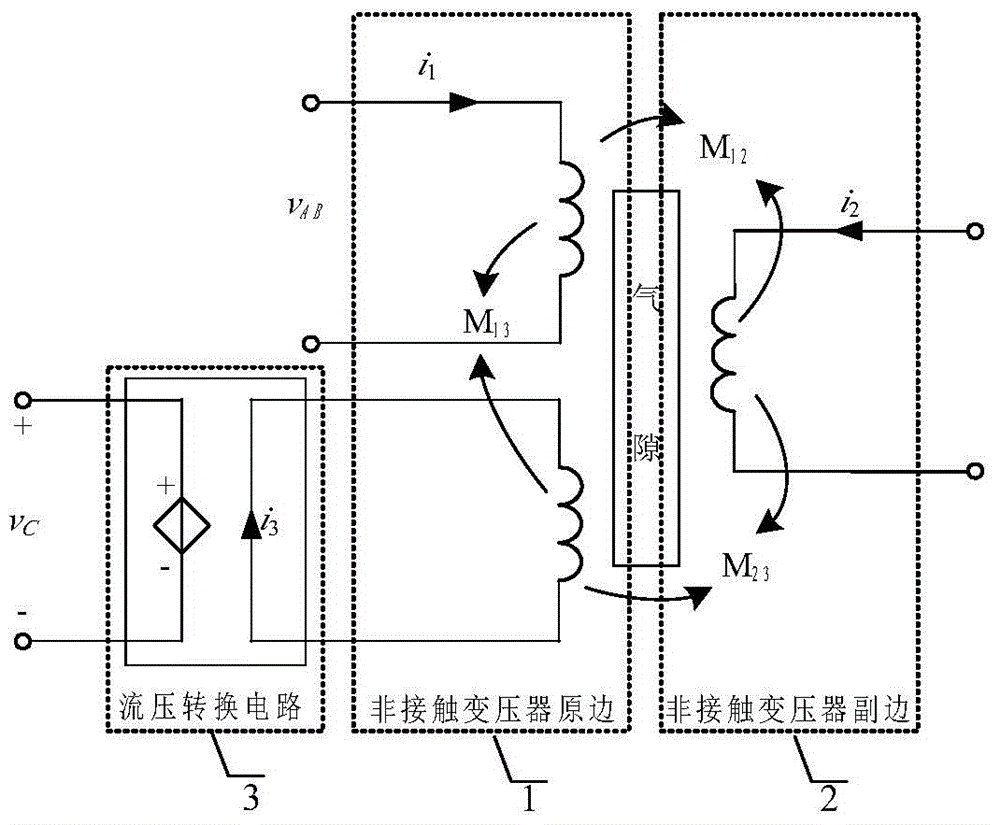

[0054] attached Figure 1-3 The structural block diagram of the improved non-contact transformer of the present invention is given, which is composed of the primary side 1 of the non-contact transformer, the secondary side 2 of the non-contact transformer and the current-voltage conversion circuit 3 .

[0055] The present invention designs that the primary side 1 of the non-contact transformer includes a primary magnetic core, a primary winding and a test winding. The test winding of the primary side 1 of the non-contact transformer is short-circuited (that is, shorted), and the primary winding can be connected in series or parallel by one winding or multiple windings. Combination composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com