Change tool and change technology for ultra-high-voltage strain insulator string

An insulator and ultra-high voltage technology, which is applied in the field of UHV tensile whole string insulator replacement tools and the replacement technology field, can solve the problem that the insulator replacement tool cannot meet the actual needs, meet the needs of construction and maintenance, reduce the difficulty of design and production, and reduce the volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

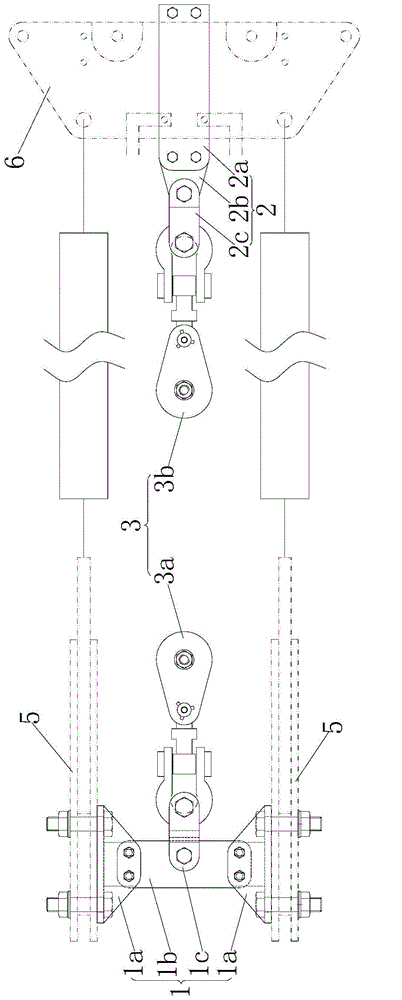

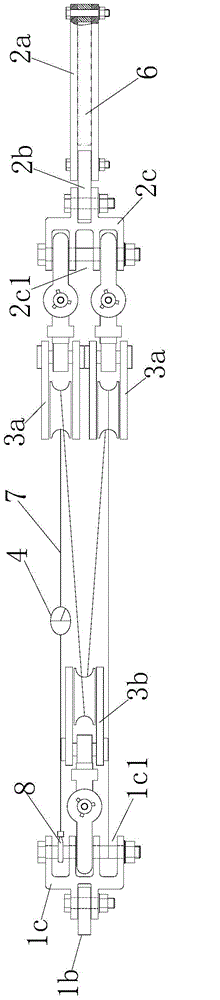

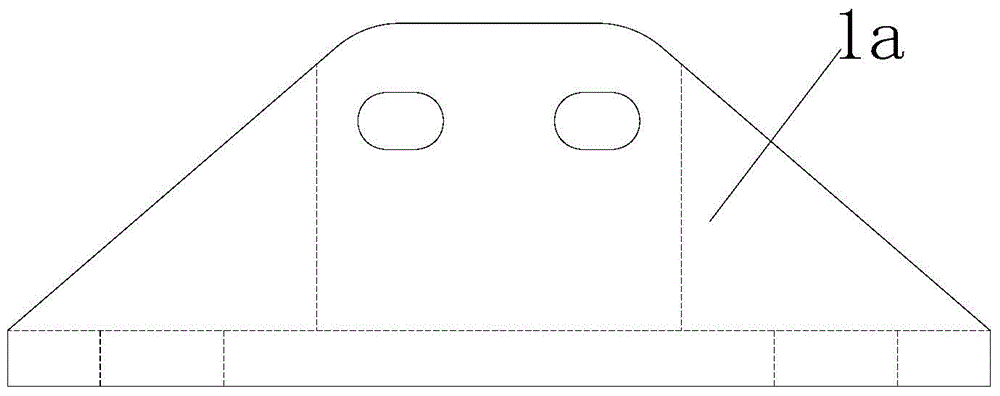

[0037] Embodiment 1: A replacement tool for UHV tension string insulators, including a hanging plate connection fitting 1 for connecting two tension adjusting hanging plates 5 installed on the tower body, clamped on the tensioning plate installed on the line The connecting plate clamping hardware 2 on the connecting plate 6, the pulley assembly 3 connected between the connecting plate connecting hardware 1 and the connecting plate clamping hardware 2, and the tightening force provided for the pulley assembly 3 Tightening device 4; said hanging plate connecting hardware 1 includes hinged seat 1a, first connecting plate 1b and first pulley seat 1c, and two said hinged seats 1a are respectively installed on said two strain-resistant adjusting hanging plates 5, The two ends of the first connecting plate 1b are respectively connected to the two hinge seats 1a, and the connecting end of the first pulley seat 1c is connected to the middle part of the first connecting plate 1b; the con...

Embodiment 2

[0044] A process for replacing a whole string of UHV tension insulators, comprising the following steps:

[0045] 1) Connect the two tension-adjusting hanging plates 5 installed on the tower body to provide the first fulcrum by using the hanging plate connecting fitting 1, wherein the hanging plate connecting fitting 1 includes a hinged seat 1a, a first connecting plate 1b and a second connecting plate 1b. A pulley seat 1c, the two hinged seats 1a are respectively mounted on the two strain-resistant adjustment hanging plates 5, and the two ends of the first connecting plate 1b are respectively connected to the two hinged seats 1a, the The connecting end of the first pulley seat 1c is connected to the middle part of the first connecting plate 1b, and the articulated end of the first pulley seat 1c is the first fulcrum;

[0046] 2) Clamp the connecting plate clamping hardware 2 on the tension connecting plate 6 installed on the line to provide a second fulcrum, wherein the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com