Stator and rotary motor comprising same

A technology for rotating electrical machines and stators, which is applied to the static parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, etc., which can solve the problems of bolt fastening force reduction, varnish insulation deterioration, fatigue, etc., and improve fastening reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

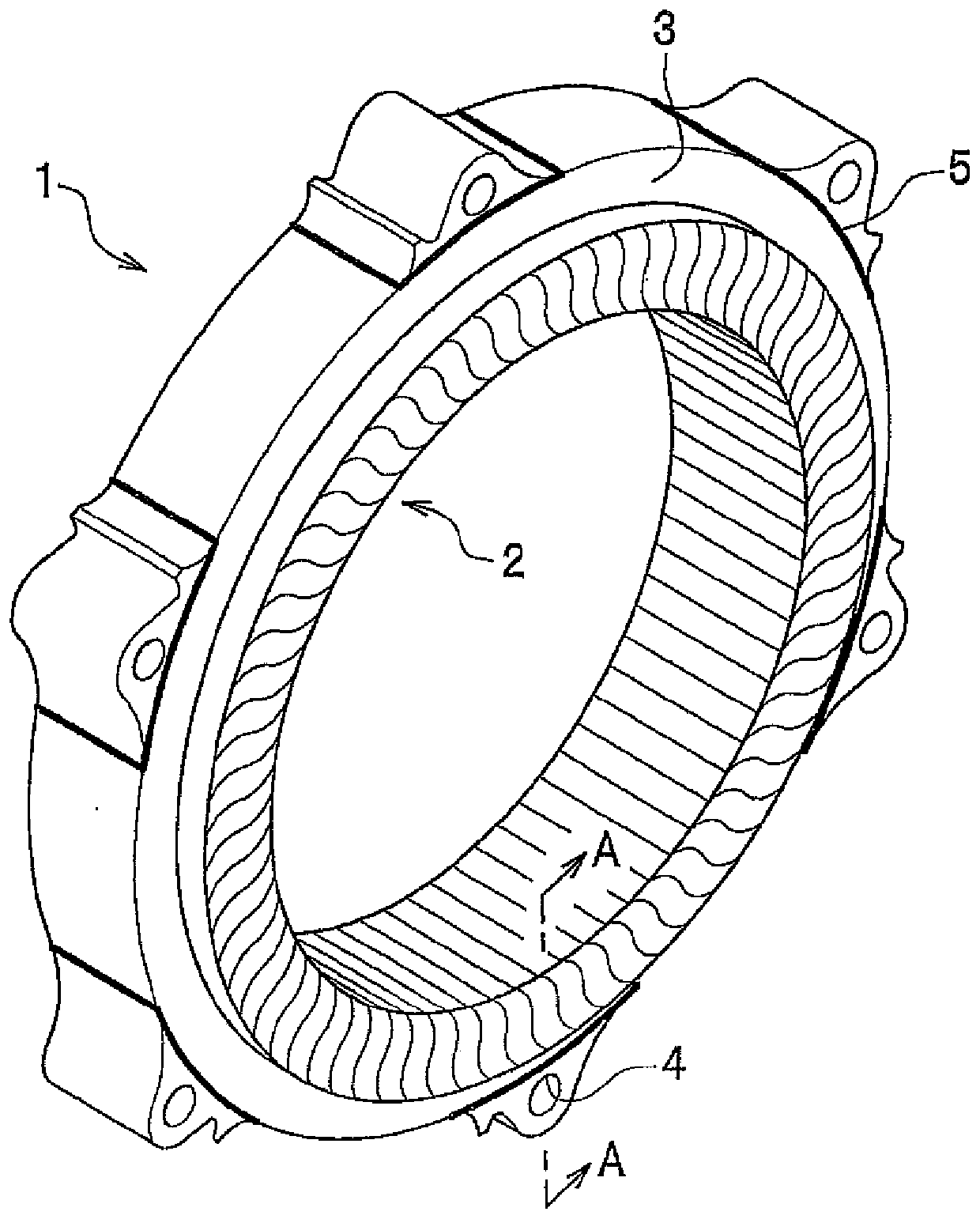

[0036] First, according to figure 1 Is a perspective view to explain the schematic structure of the stator 1 of the embodiment.

[0037] Here, the rotating electric machine having the stator 1 of the embodiment operates as a motor or a generator of a vehicle such as an electric vehicle including a hybrid vehicle and a fuel cell vehicle.

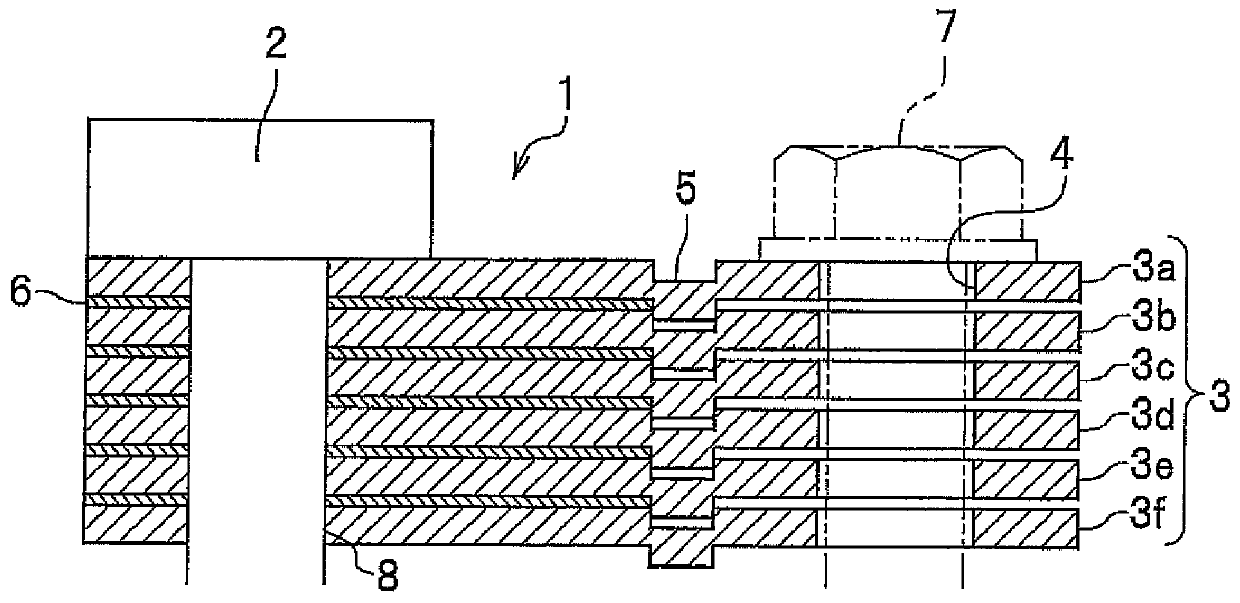

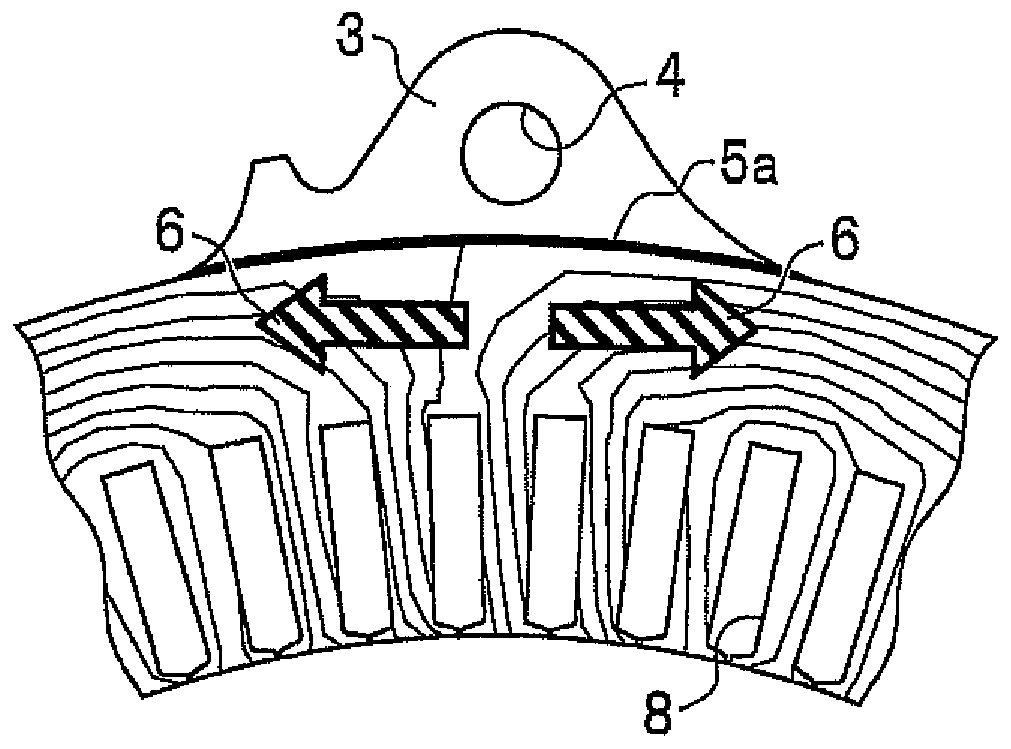

[0038] figure 1 The stator 1 consists of a stator core 3 and a slot 8 wound on the inside of the stator core 3 (refer to figure 2 ) On the stator coil 2. In addition, the stator 1 is bolted to a housing (not shown) of the rotating electric machine with a predetermined axial force through a fastening hole 4 provided in the outer peripheral portion of the stator core 3.

[0039] In addition, a rotor (not shown) of the rotating electric machine is inserted inside the stator 1.

[0040] The stator core 3 is formed by laminating plate-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com