Double-stator axial magnetic field motor

An axial magnetic field and dual stator technology, which is applied in electrical components, electromechanical devices, etc., can solve the problems of difficulty in current control of dual stator axial magnetic field motors, reduce the difficulty of current control, increase torque density, and achieve structural design. flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

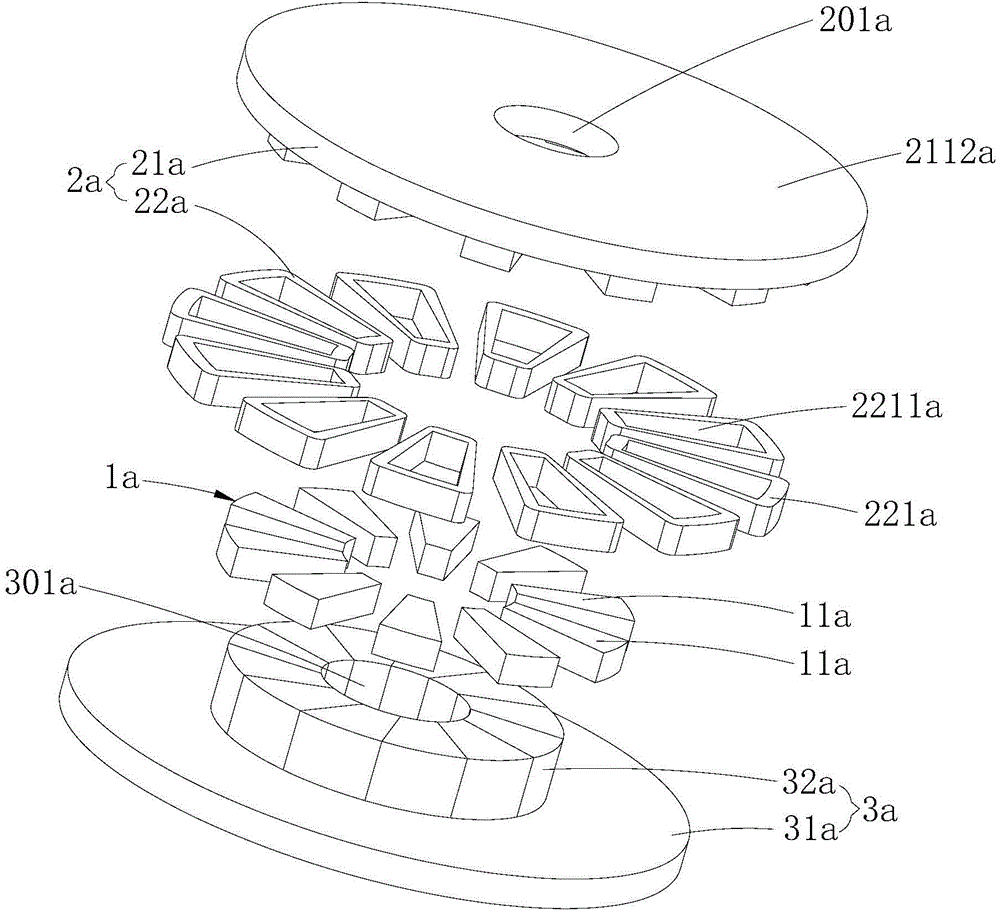

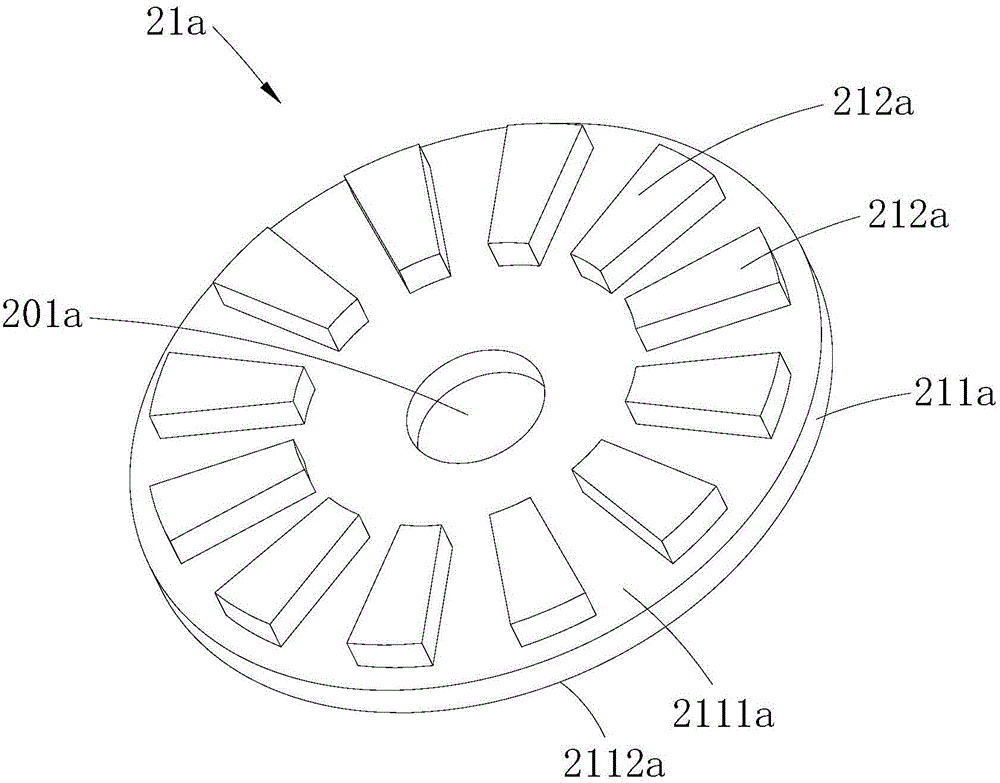

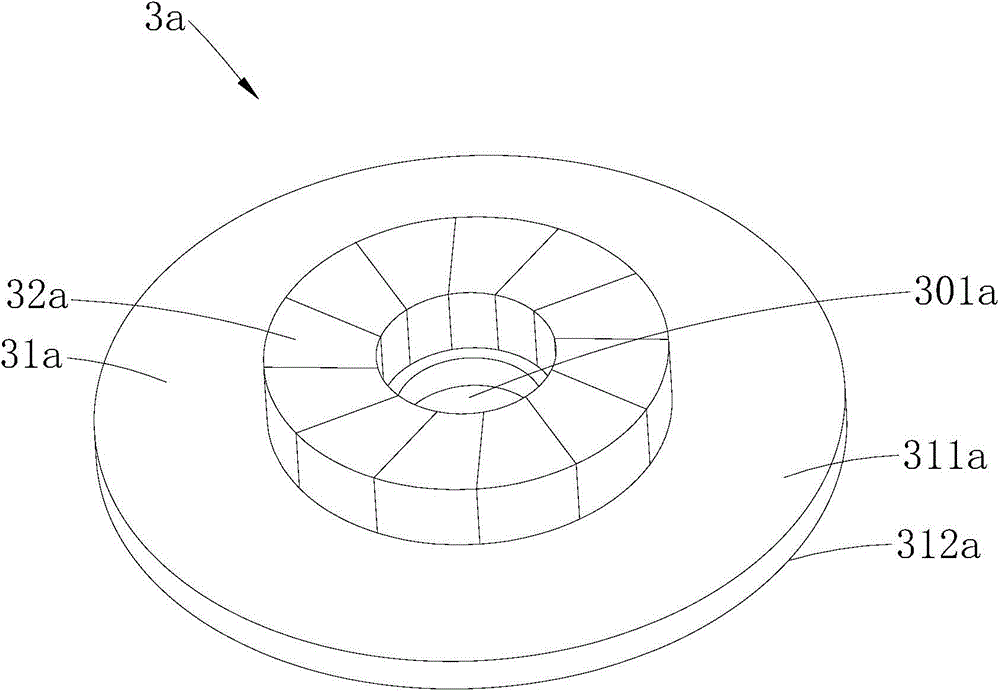

[0026] Such as Figure 1~3 As shown, the double-stator axial field motor provided by Embodiment 1 of the present invention includes a rotor 1a, an armature stator 2a arranged on one axial side of the rotor 1a, and an excitation stator 3a arranged on the other axial side of the rotor 1a The armature stator 2a includes an armature core 21a and an armature winding 22a disposed on the armature core 21a, and the field stator 3a includes a field core 31a and several magnetic poles 32a protruding from the field core 31a. The control current of the armature stator 2a is an alternating current, and no control current is set on the excitation stator 3a (the excitation stator 3a adopts permanent magnet excitation), that is, the input current of the armature winding 22a is an alternating current, and no input current is set on the magnetic pole 32a In this way, since the control currents of the armature stator 2a and the excitation stator 3a are different, it effectively reduces the diffi...

Embodiment 2

[0041] Such as Figure 4 As shown, the same as Embodiment 1, the dual-stator axial field motor provided in this embodiment also includes a rotor 1b, an armature stator 2b disposed on one axial side of the rotor 1b, and an axial stator 2b disposed on the axial side of the rotor 1b. The field stator 3b on the other side, the armature stator 2b includes the armature iron core 21b and the armature winding 22b arranged on the armature iron core 21b, the field stator 3b includes the field core 31b and a number of protrudingly arranged on the field core The magnetic pole 32b on the 31b; and the main difference between this embodiment and the first embodiment is the design of the excitation stator 3b, which is embodied in that the magnetic pole 32a in the first embodiment is a permanent magnet located on the excitation core 31a, and the excitation The stator 3a does not need to input control current during the working process; and in this embodiment, the magnetic pole 32b includes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com