Thermoplastic Containers

A thermoplastic material and container technology, applied in the direction of rigid containers, containers, and the arrangement combined with the fuel supply of internal combustion engines, can solve the problems of complex container weight, fuel leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

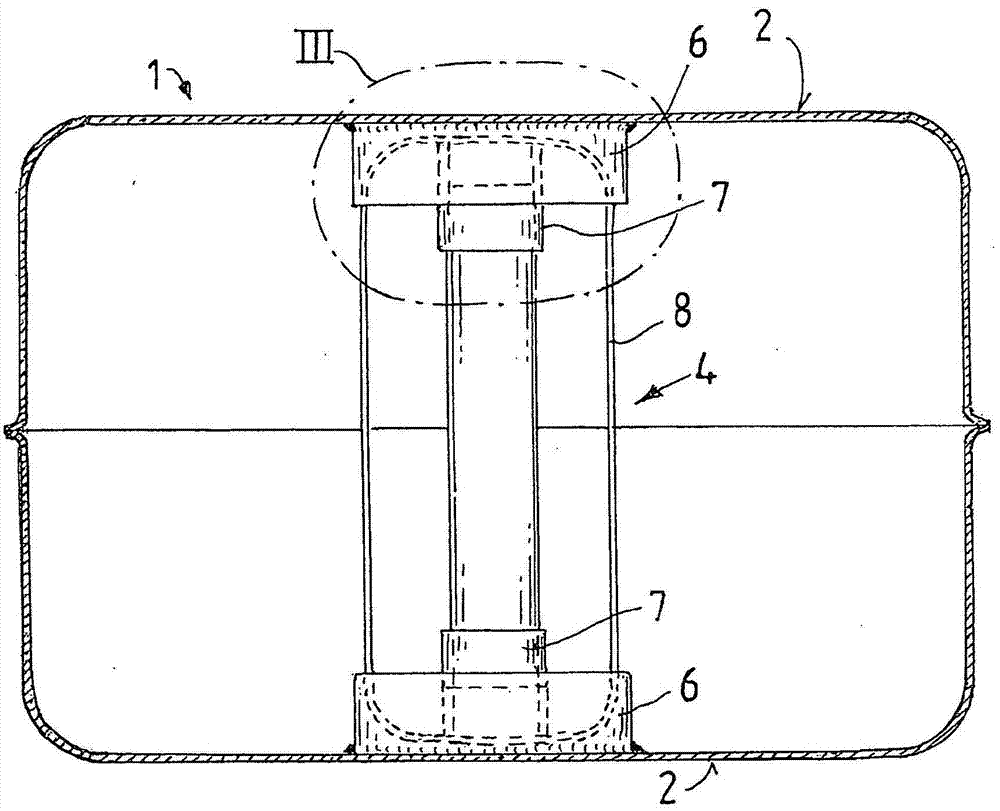

[0045] exist figure 2 In, a container 1 as provided by the invention is shown in section in greatly simplified form. The container 1 may for example be formed as an integrally formed extrusion blow molded fuel tank. This container comprises a container wall 2 enclosing a cavity 3 to be filled with liquid. The container wall 2 consists of a thermoplastic material, preferably a multilayer extrusion based on polyethylene.

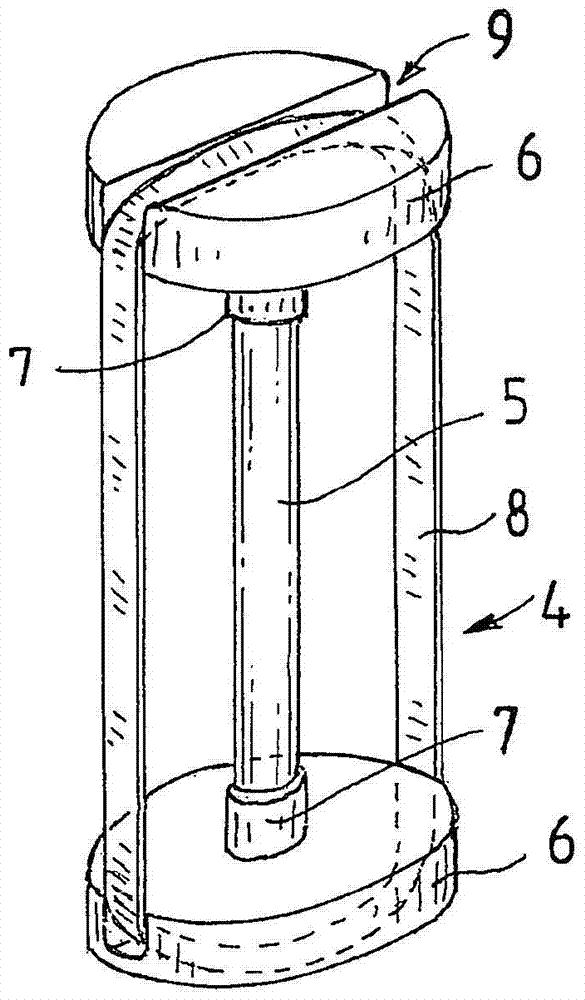

[0046] The large-area opposing regions of the container wall 2 , which have a relatively low moment of area area, are supported on one another by means of multipart supports 4 . The support 4 is in figure 1 is shown in perspective view.

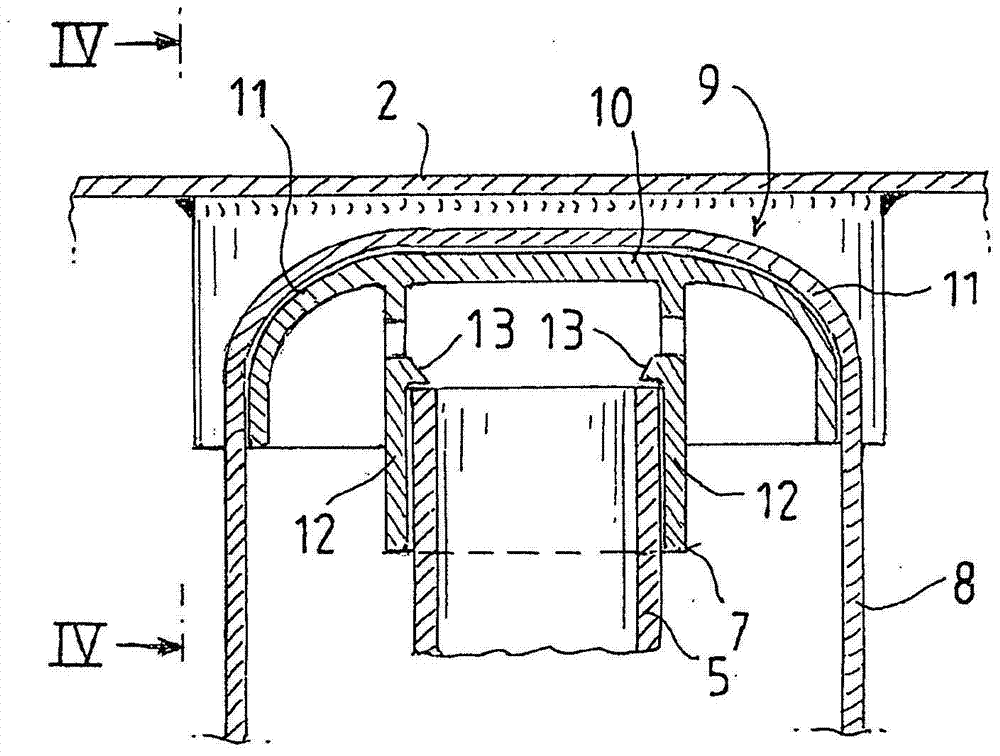

[0047] This support 4 comprises a support column 5 provided at each end with a base 6 of thermoplastic material, the plastic of which is compatible with the plastic of the container wall 2 in terms of weldability.

[0048] The base 6 fits onto the support column 5 at each end and engages or clips thereto. The support c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com