Rotary chamfering device for anchor plates

A chamfering device, rotary technology, applied in the field of rotary anchor plate chamfering device, can solve problems such as low production efficiency, achieve the effects of improving production efficiency, avoiding repeated installation, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

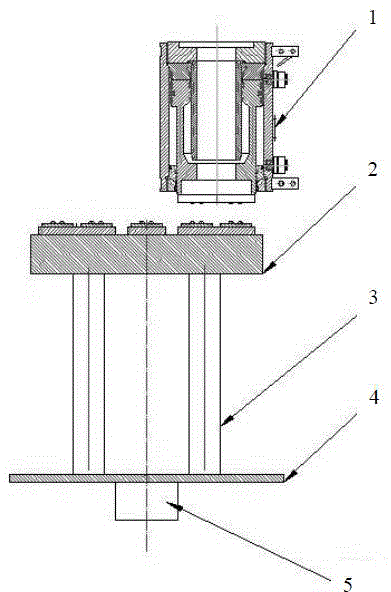

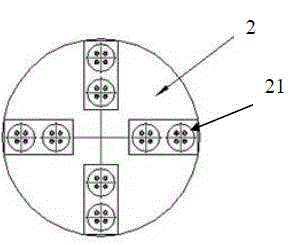

[0011] figure 1 Shows the overall structure diagram of a rotary anchor plate chamfering device provided by the present invention, the device mainly includes a punching device 1 and a workbench, the punching device 1 is a jack, and the workbench is mainly composed of a rotating disk tooling 2 , a strut 3, a chassis 4 and a rotating shaft 5 are combined, the lower end of the rotating disk tooling 2 is connected to the strut 3, the other end of the strut 3 is connected to the chassis 4, the lower end of the chassis 4 is provided with a rotating shaft 5, and the rotating The shaft 5 drives the chassis 4 to rotate, and the chassis 4 drives the rotary tooling 2 through the support rod 3. When chamfering, align the hole position of the working anchor plate with the protruding chamfering column on the rotary tooling 2 and place it. Extrude the tooling for chamfering; turn on the oil pump jack piston to extend down to pressurize the tooling, and the chamfering is completed. The piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com