Assembled milling cutter tool

A milling cutter and tooling technology, applied in the field of assembling milling cutter tooling, can solve problems such as cost surge and safety hazards, and achieve the effect of eliminating accidents, cutting safety, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

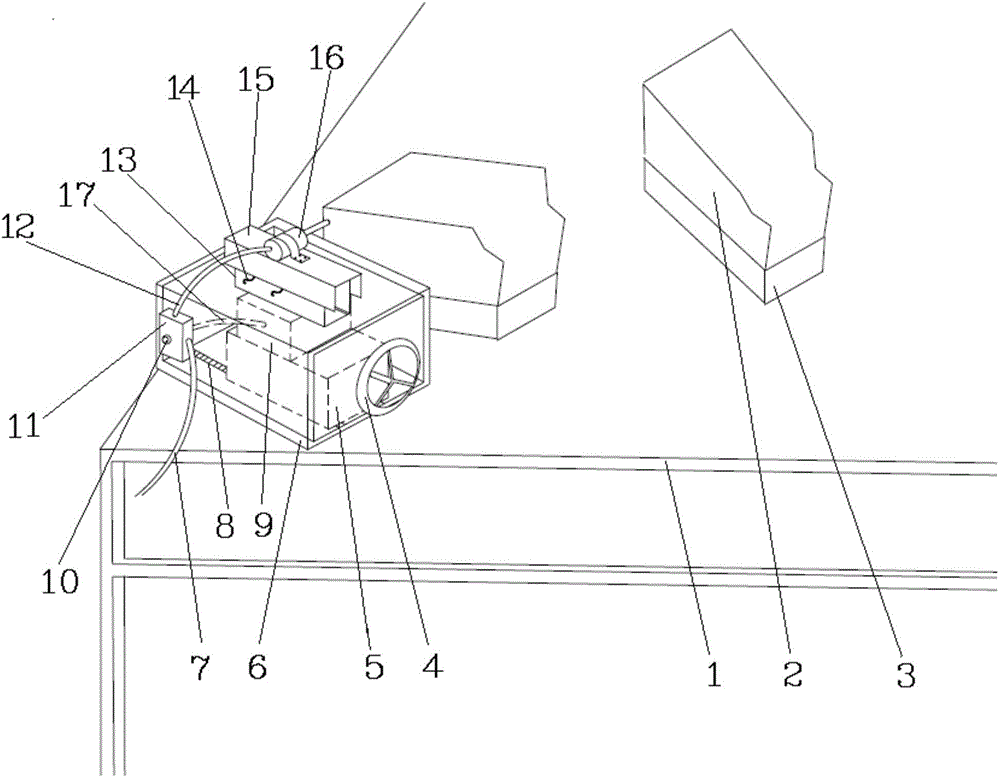

[0015] Such as figure 1 As shown, a tool for assembling a milling cutter includes a workbench 1, a workpiece 2, a fixed seat 3, a crank handle 4, a horizontal moving table 5, a dustproof box 6, an air intake pipe 7, a slide rail 8, and a vertical moving table 9, Air valve button 10, air valve 11, the first air outlet pipe 12, the second air outlet pipe 17, track table 13, track groove 14, support seat 15, milling cutter driver 16, workbench 1 is that rectangle is fixed on by four legs and feet On the ground, a dust-proof box 6 is fixed on a corner of the workbench 1, an air valve 11 is fixed on the side wall of the dust-proof box 6, and two rows of Slide rail 8, two rows of slide rails 8 are equipped with horizontal moving platform 5, horizontal moving platform 5 has thread holes along slide rail 8, a screw mandrel is housed in the thread hole, and the other end of the thread hole stretches out dustproof box 6 side and It is connected and fixed with the center of the rocking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com