Plastic injection mould of domed plastic part

A technology for plastic parts and injection molds, which is applied in the field of injection molds for plastic domes, and can solve problems such as unstable jet flow in melt channels, poor surface quality of dome plastic parts, and failure to meet electroplating requirements, etc., to achieve good surface quality , prevent jet flow, avoid the effect of snake flow pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below in conjunction with accompanying drawing.

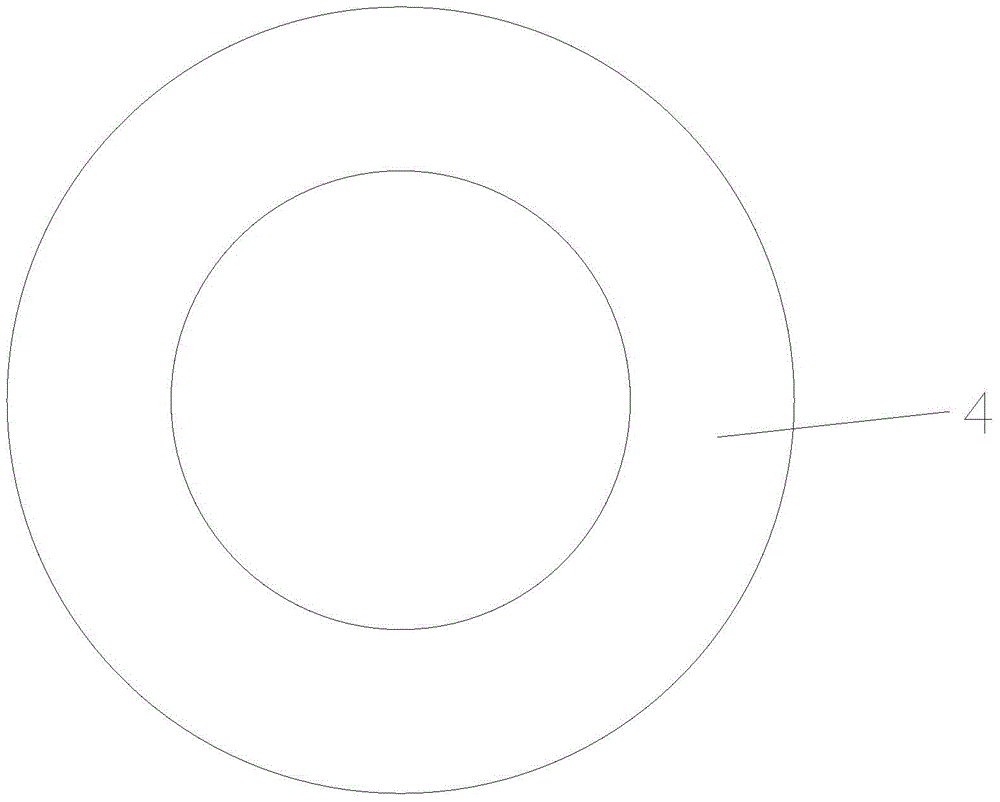

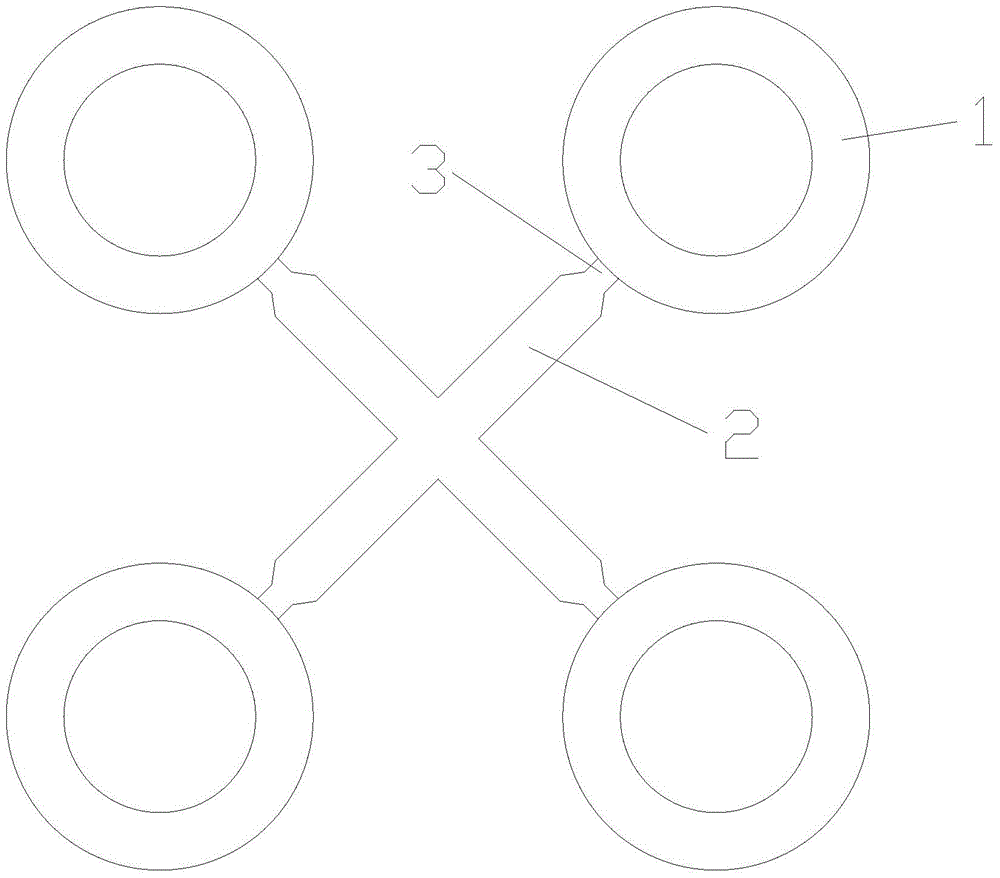

[0014] as attached Figure 4 A kind of dome plastic part injection mold of the present invention as shown, comprises dome plastic part mold cavity 1, runner 2 and sprue 3, and described dome plastic part mold cavity 1 is provided with four, and described The cavity 1 of the four dome plastic parts is arranged in a square, and the flow channel 2 communicates with the cavity 1 of the dome plastic part through the pouring port 3, and the flow channel 2 is in the shape of "H"; the shape of the "H" The four sprues 3 of the runner 2 are tangent to the circular wall at the bottom of the mold cavity 1 of the dome plastic part.

[0015] In the injection mold of the round cover plastic part of the present invention, since the flow channel is "H" type, the four spouts of the "H" type flow path are tangent to the circular wall at the bottom of the cavity of the round cover plastic part, and the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com