Positioning device for lower trolley of steel pipe binding machine

A technology of positioning device and bundling machine, which is applied in the parts and packaging of bundling machinery, can solve the problem of not adapting to the precise positioning equipment of the lower trolley of the steel pipe baler, and achieve the purpose of simplifying parts, ensuring the life of parts, and improving positioning accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

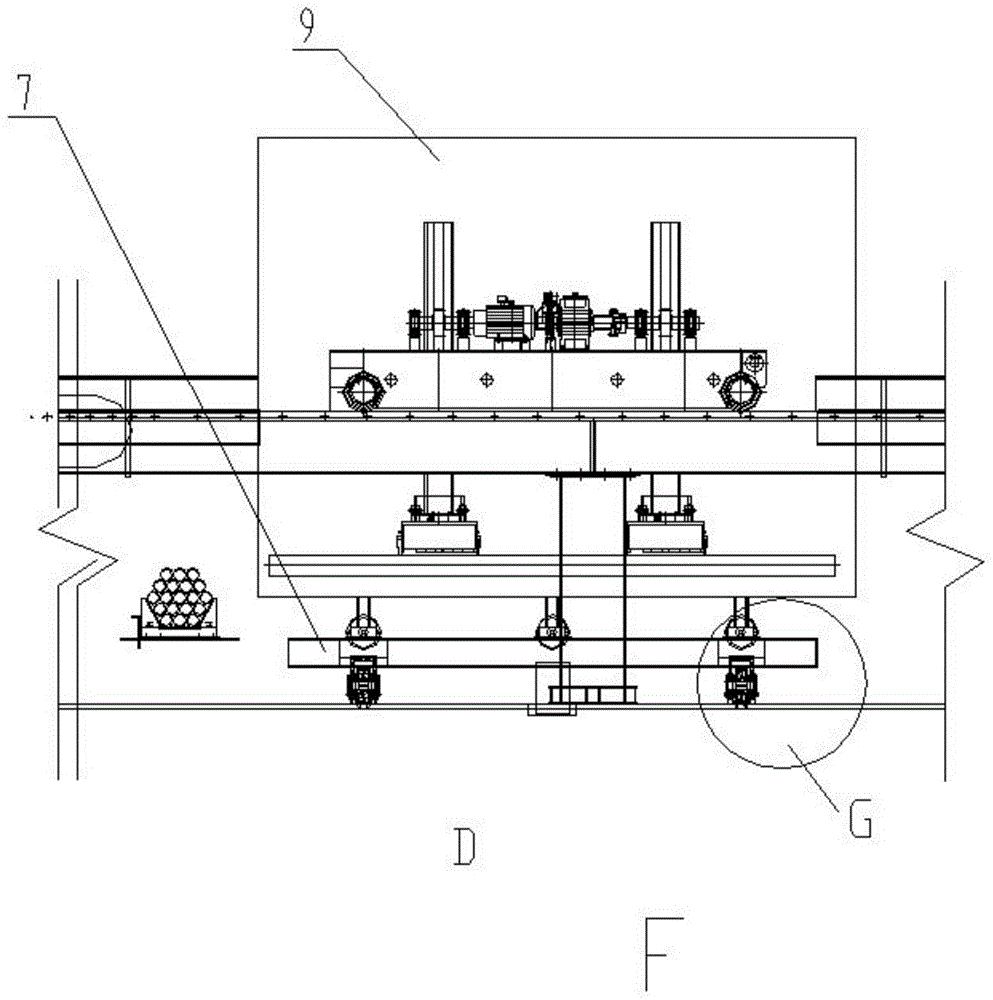

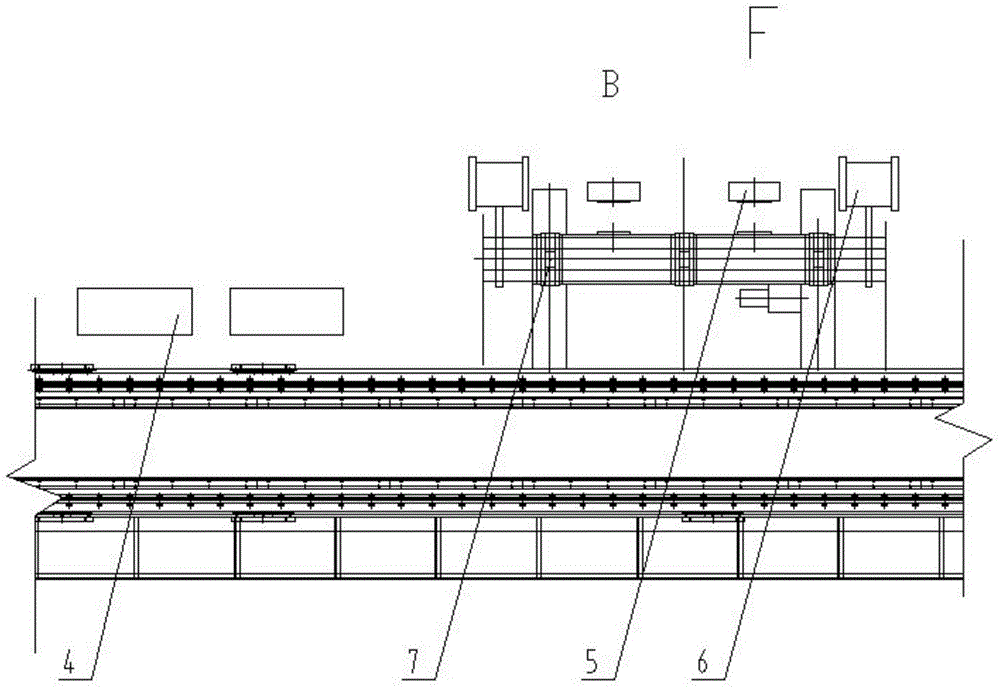

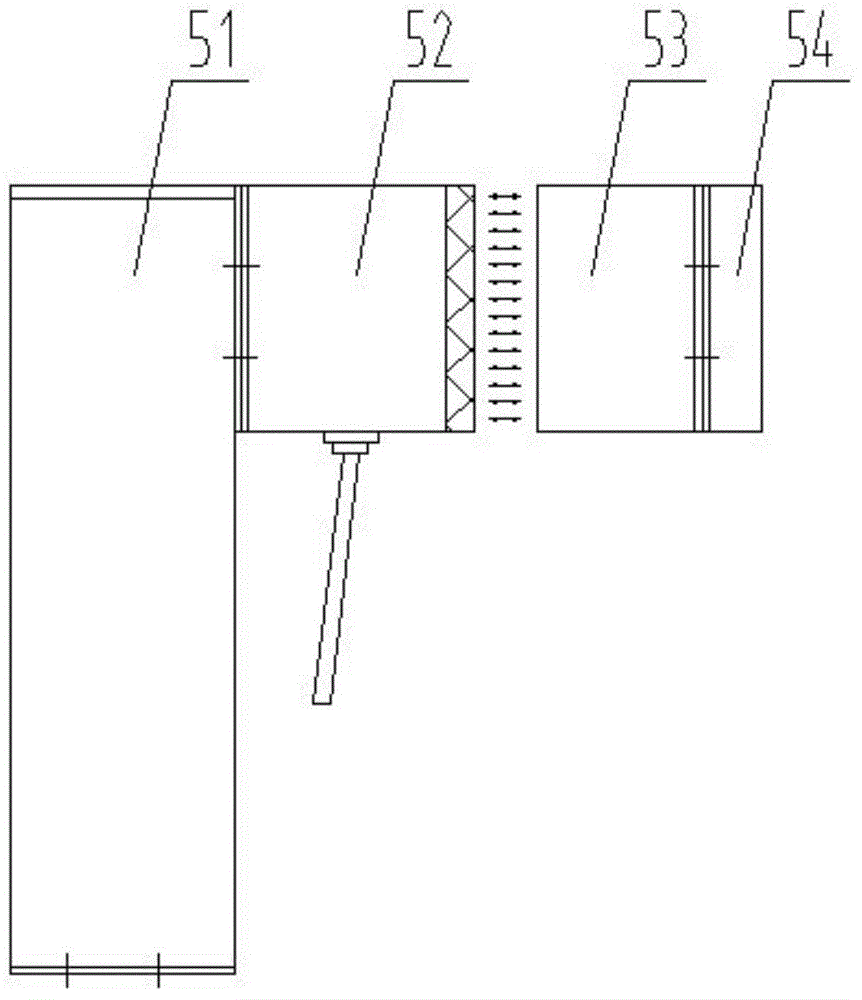

[0024] Embodiment 1: A positioning device 5 for the lower trolley 7 of a steel pipe binding machine, see Figure 1 to Figure 6 , a positioning device 5 for the lower trolley 7 of a steel pipe binding machine, the positioning device 5 is installed on the lower trolley 7, the positioning device 5 includes an adsorption mechanism and an electrical system 4 for controlling the opening or closing of the adsorption mechanism, and the adsorption mechanism is installed on the lower trolley 7 Need to be fixed on the corresponding station.

[0025] Adsorption mechanism comprises the positioning iron block 53 installed on the binding machine, the electromagnetic chuck 52 installed on the dolly of the lower floor, and the electromagnetic chuck 52 power supply device that provides the power source for the electromagnetic chuck 52, so that when the electromagnetic chuck 52 and the positioning iron block 53 When the distance is less than 50mm, the electromagnetic chuck 52 is energized.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com