Pipeline scrolling device

A pipeline reel and tube reel technology, applied in the field of pipeline reel, can solve the problems of weak fastening, wear and damage of integral structural components, burning of point shaft cores, etc., so as to achieve convenient, fast and safe installation, convenient maintenance and disassembly, and extended use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

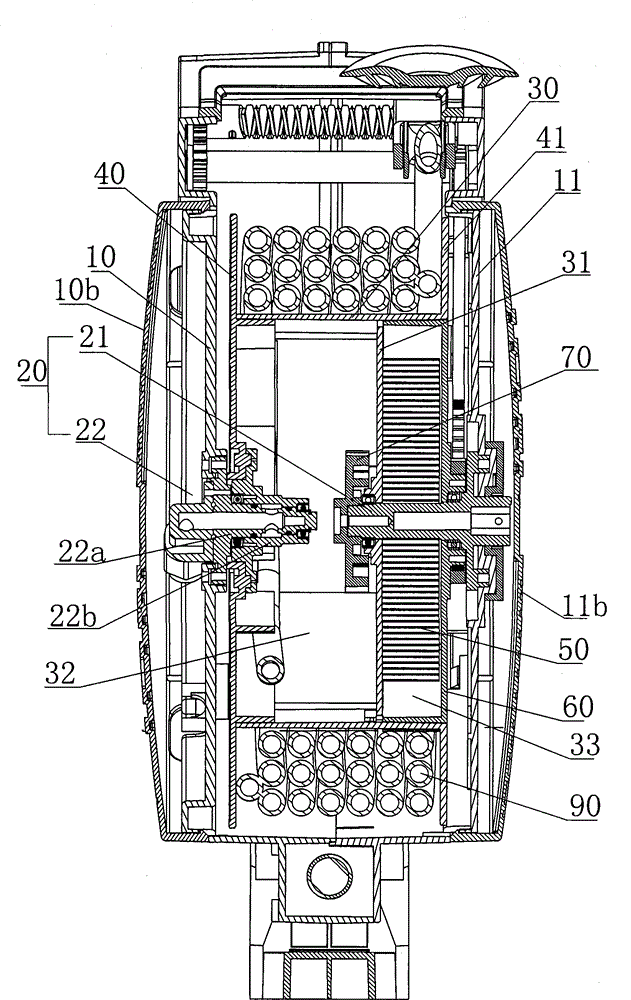

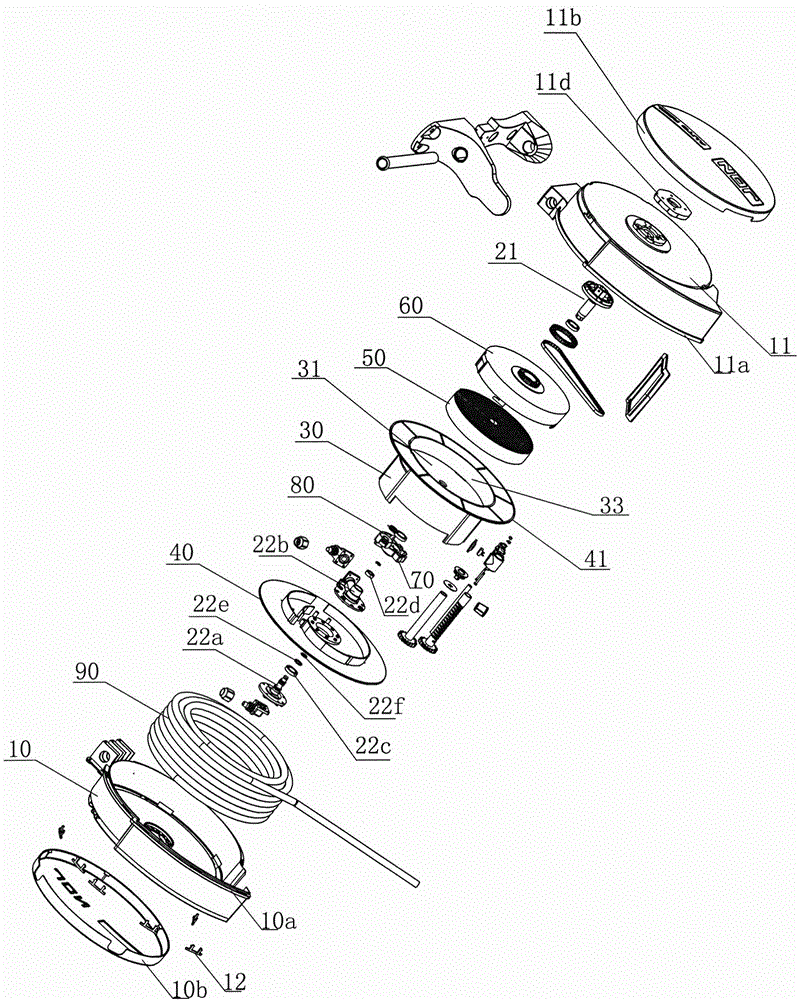

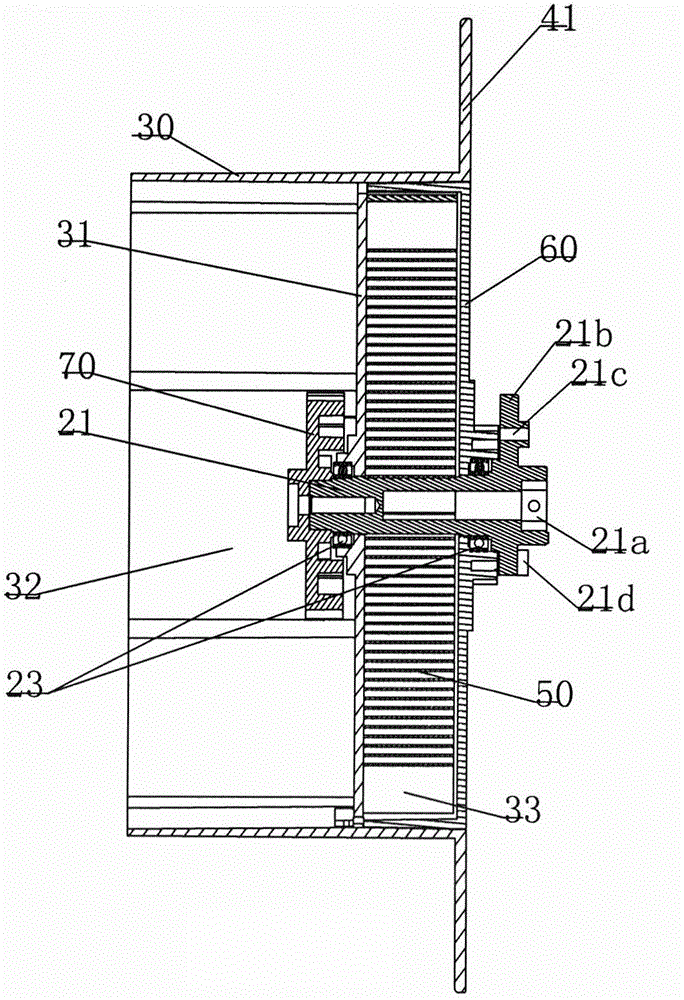

[0062] Such as Figure 1 to Figure 18As shown, a pipeline reel of the present invention includes left and right housings 10, 11, a shaft center 20, a reel tube 30, left and right reels 40, 41 and clockwork springs 50 on both sides of the reel tube 30, and the reel tube The tube 30 is positioned between the left and right shells 10, 11 through the axis 20, the axis 20 includes the left and right independent rotation conversion shaft 22 and the spring spring shaft 21, and the right side of the coil tube 30 is provided with a radial partition The plate 31 asymmetrically separates the independent large and small chambers 32, 33. The small chamber 33 on the right is provided with a cylindrical box 60 matching it, and the clockwork spring shaft 21 is arranged on the winding tube. The right side of 30 is interspersed in the box body 60, the right end is fixed with the right housing 11, and the left end extends in the large chamber 31 to set a fixed ratchet 70, and the radial partitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com