Amorphous alloy three-dimensional roll-core annealing furnace and annealing method

A technology of three-dimensional coiled iron core and amorphous alloy, which is applied in furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of inability to meet the annealing requirements of amorphous alloy three-dimensional coiled iron cores, and achieve the effect of ensuring electromagnetic performance and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

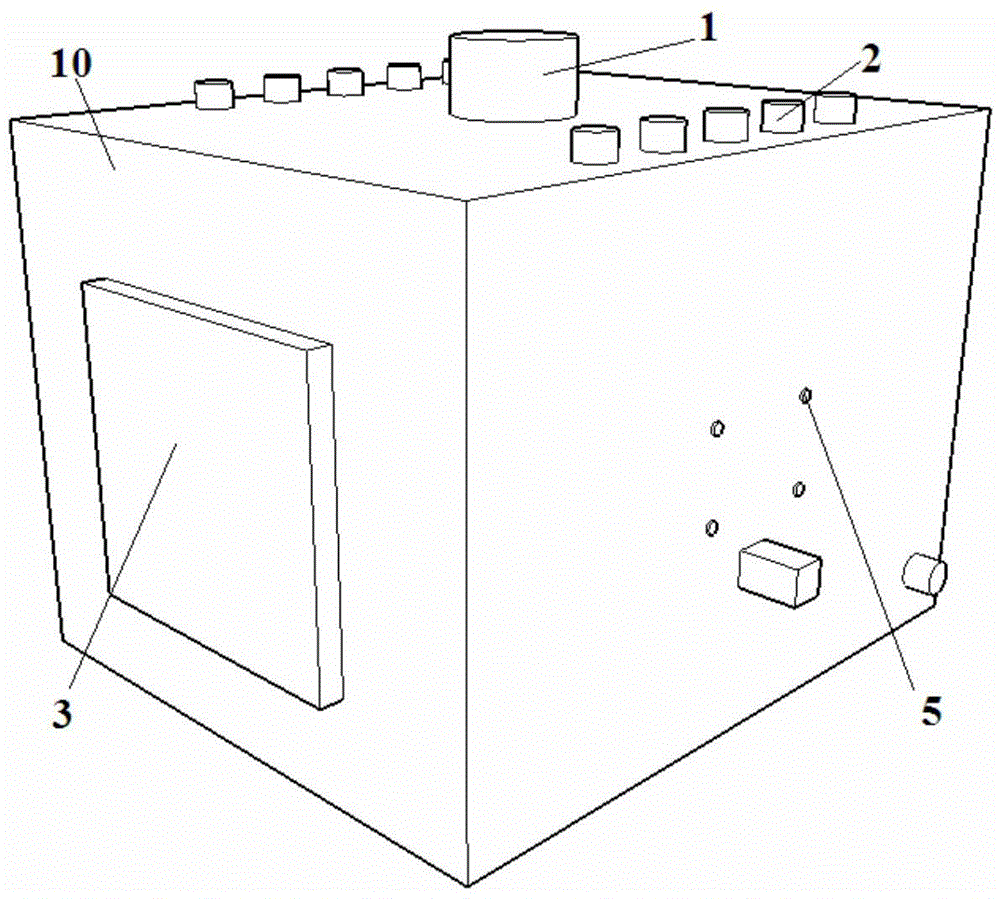

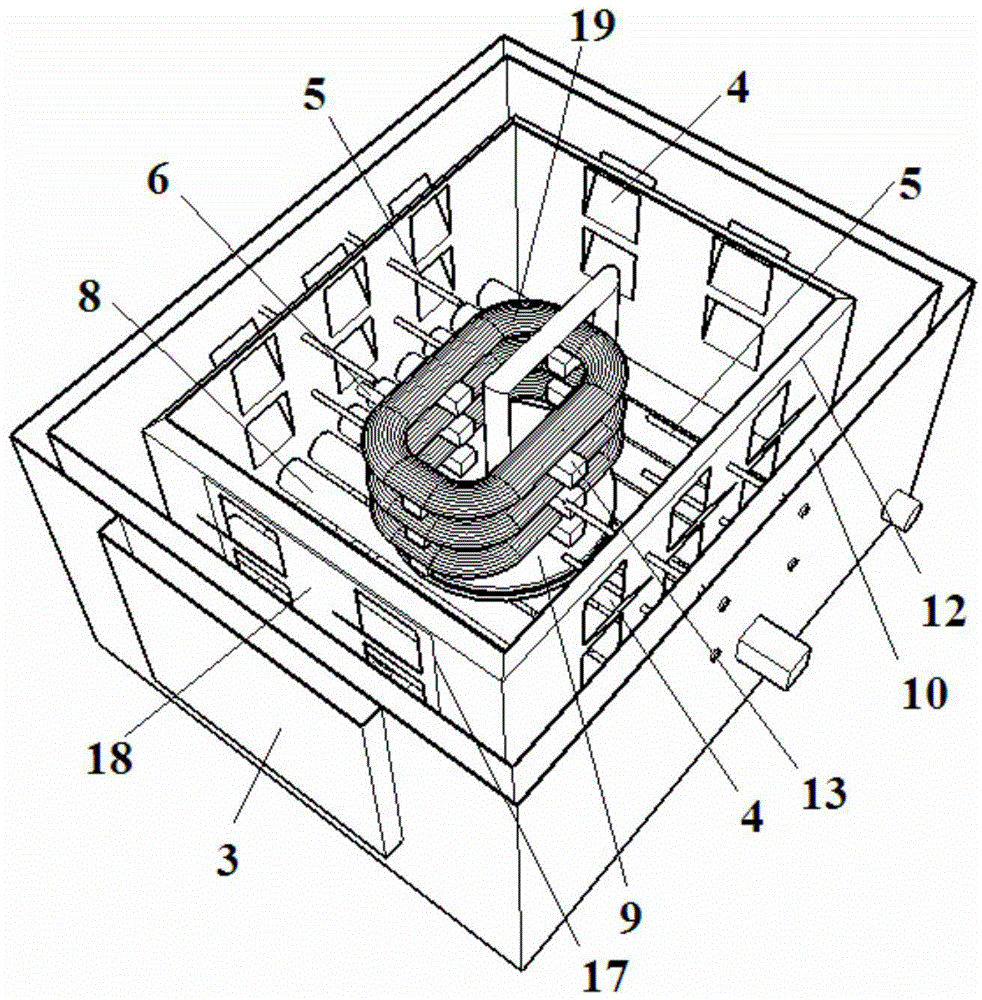

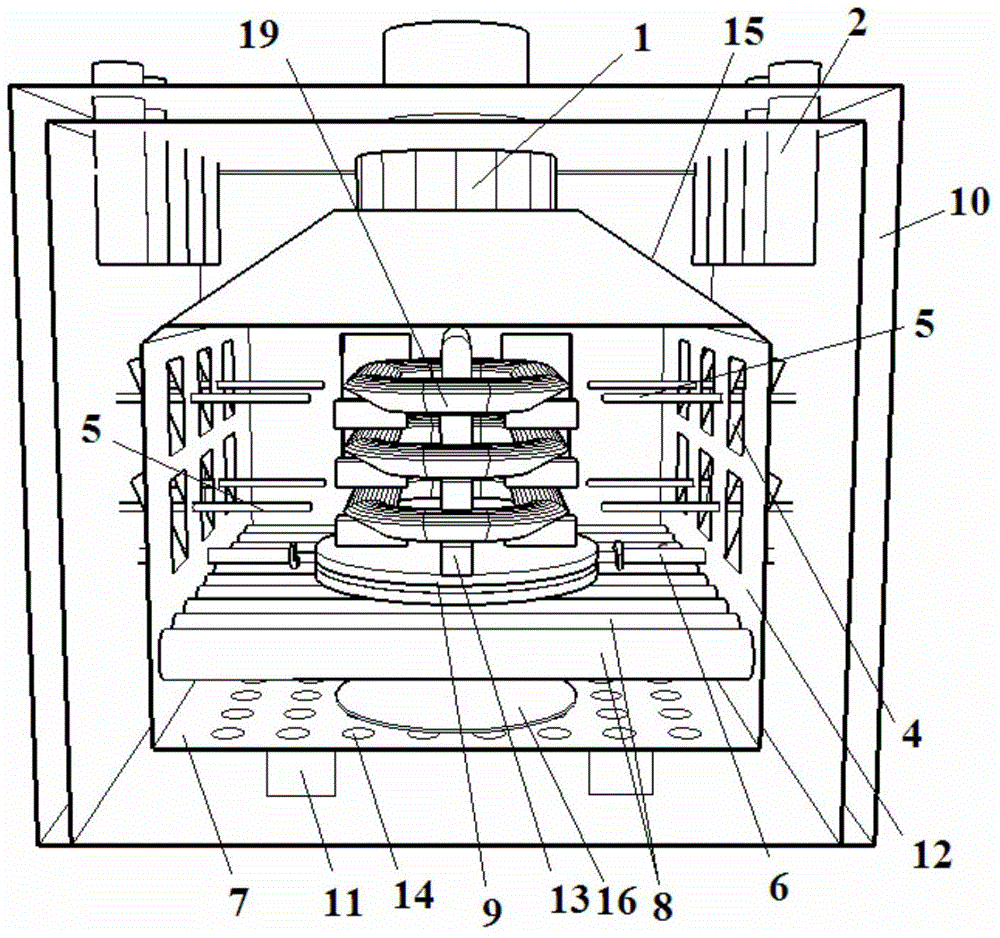

[0022] like Figure 1~3 The shown amorphous alloy three-dimensional wound iron core annealing furnace includes a cooling shell 10, a circulation fan 1 installed in the middle of the top of the cooling shell 10, heaters 2 installed on both sides of the top of the cooling shell 10, and fixed on the cooling wall by a bracket 11. The heating chamber 12 inside the casing 10, the horizontal roller group 8 installed between the left and right side walls of the heating chamber 12, the tray 9 placed on the horizontal roller group 8, and the three-dimensional wound iron core support 13 arranged on the top surface of the tray 9, wherein , the left side wall of the cooling housing 10 is provided with an electrode 6 passing through the side wall of the heating chamber 12 and facing the heating station of the tray 9, and the right side wall of the cooling housing 10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com