Convective dyeing vat

A technology for dyeing vats and vats, which is applied in the field of dyeing vats with good internal convection effects. It can solve the problems of poor fabric dyeing pass rate, poor dye fluidity, and difficult coloring of fabrics where it gathers, so as to improve the dyeing effect. The effect of preventing dead spots of dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

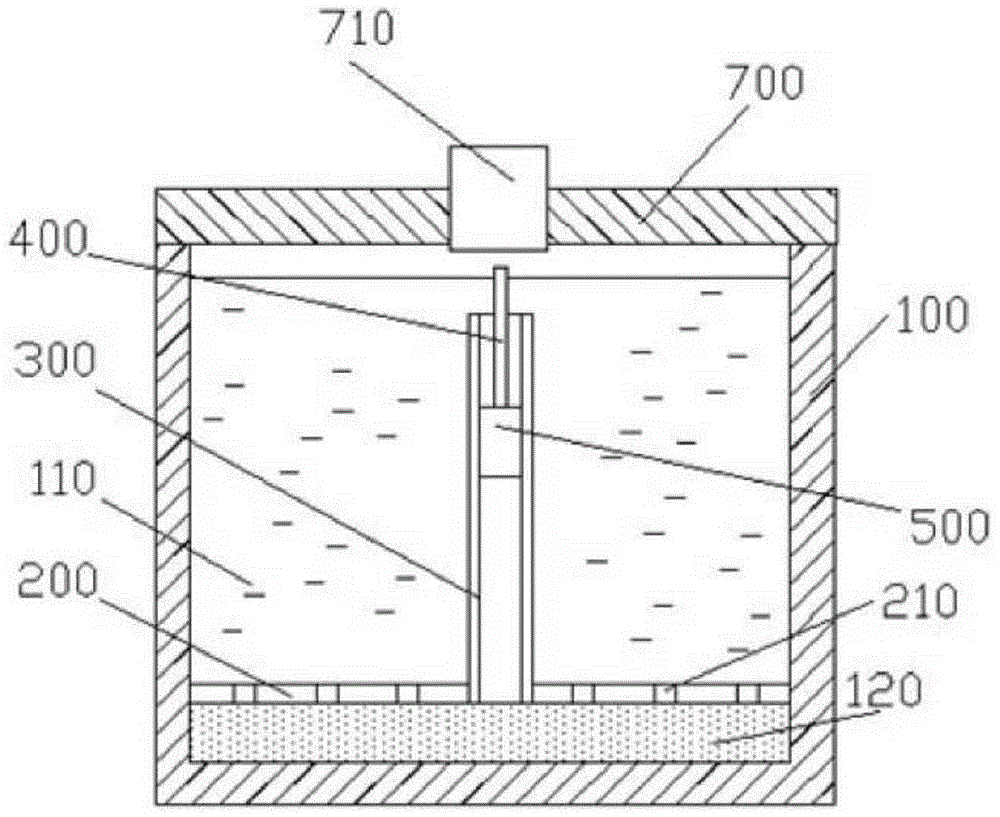

[0016] In this example, see figure 1 , the convection dyeing vat includes a dyeing vat body 100 and a vat cover 700, a circulation pipe 300 is arranged in the dye vat body 100, and the two ends of the circulation pipe 300 are respectively located at the upper and lower parts of the dyeing vat body 100 and both ends are lower than The dye liquid surface in the dye vat body 100, the dye vat body 100 is provided with an air circulation pipeline 400, and the two ends of the air circulation pipeline 400 are respectively located at the upper and lower parts of the dye vat body 100 and the air circulation pipeline 400 The upper end of the upper end is higher than the dye liquid level in the dye vat body 100, and both the circulation pipeline 300 and the air circulation pipeline 400 are provided with pump bodies.

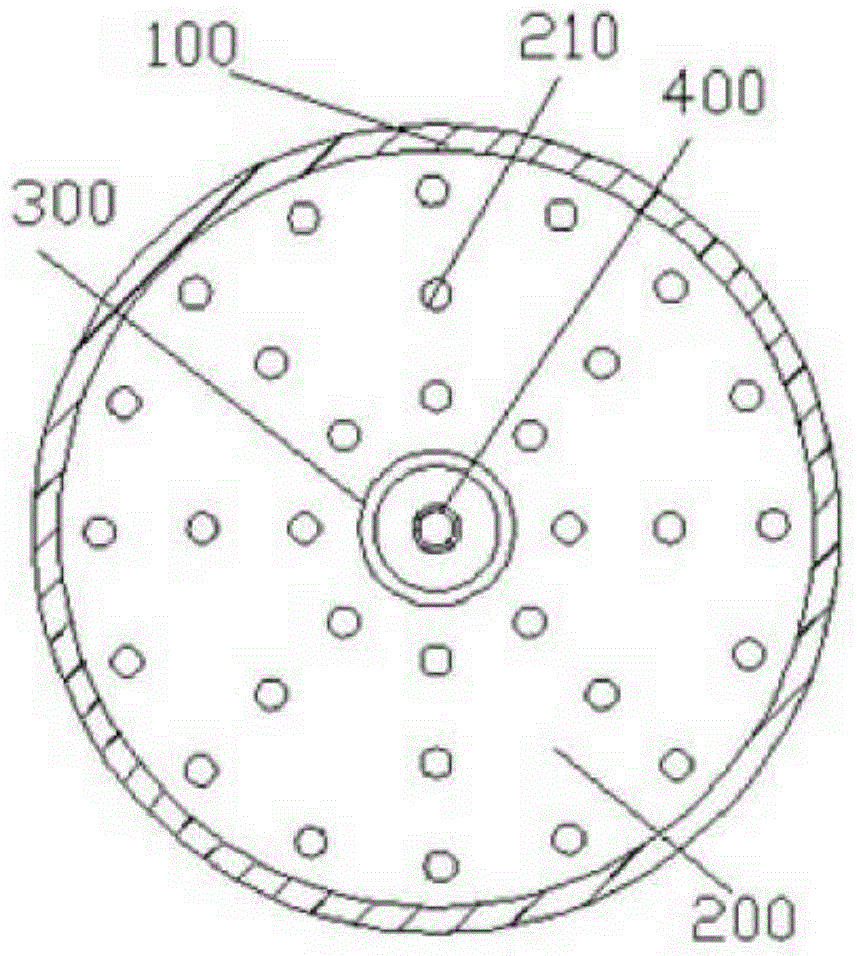

[0017] refer to figure 2 , the bottom of the dye vat b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap