Two-sided galling process and equipment thereof

A kind of process, double-sided technology, applied in the direction of fabric surface trimming, two or more different solvent-based treatment materials, textiles and papermaking, etc., can solve the problems of complex production process, easy to wrinkle, dull, etc., and achieve stability Good performance and strong hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

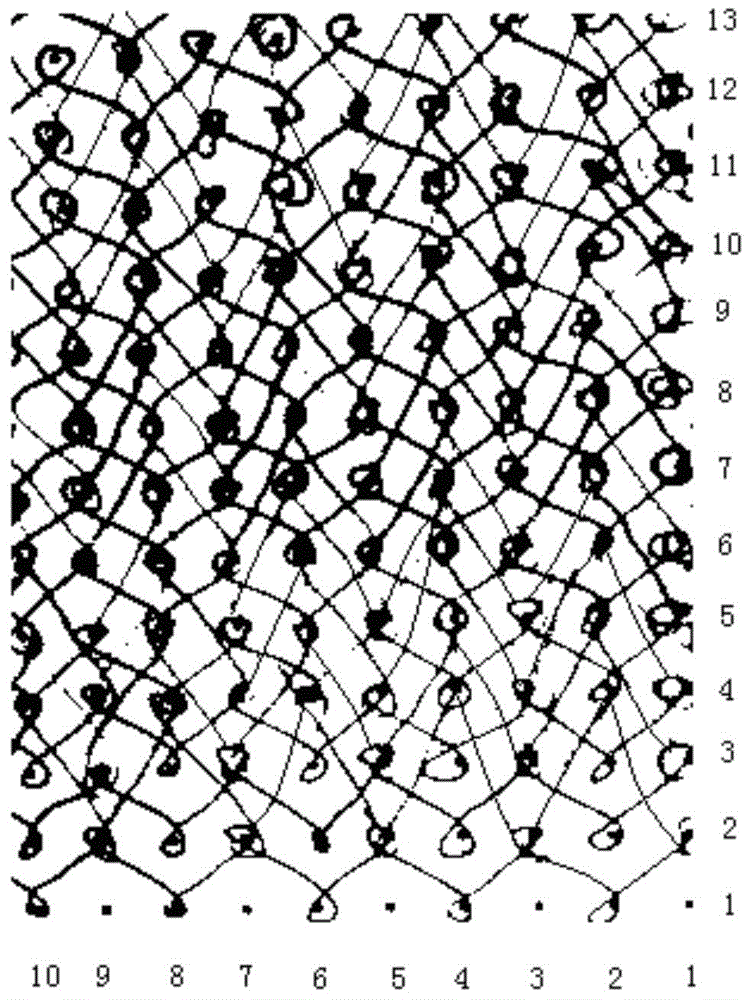

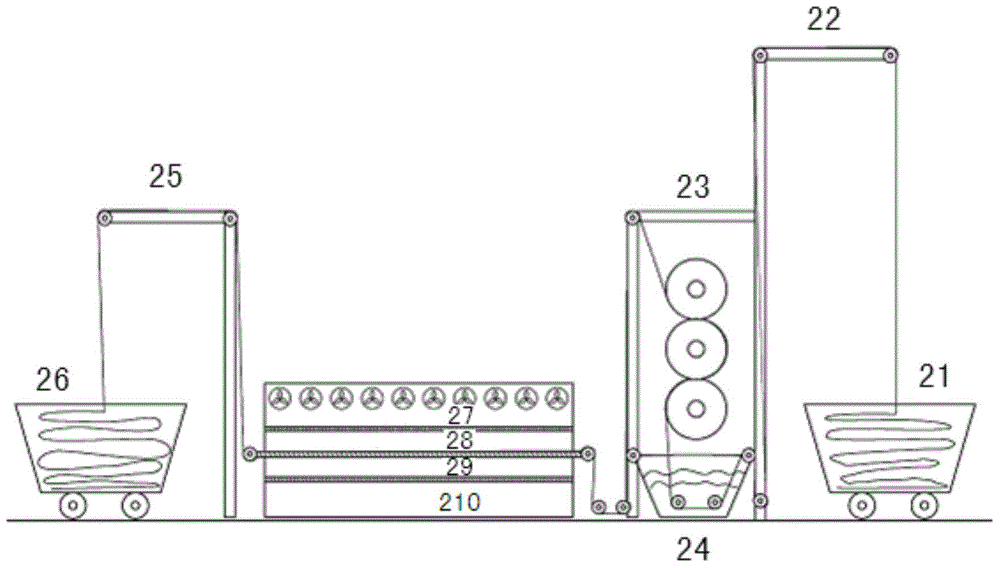

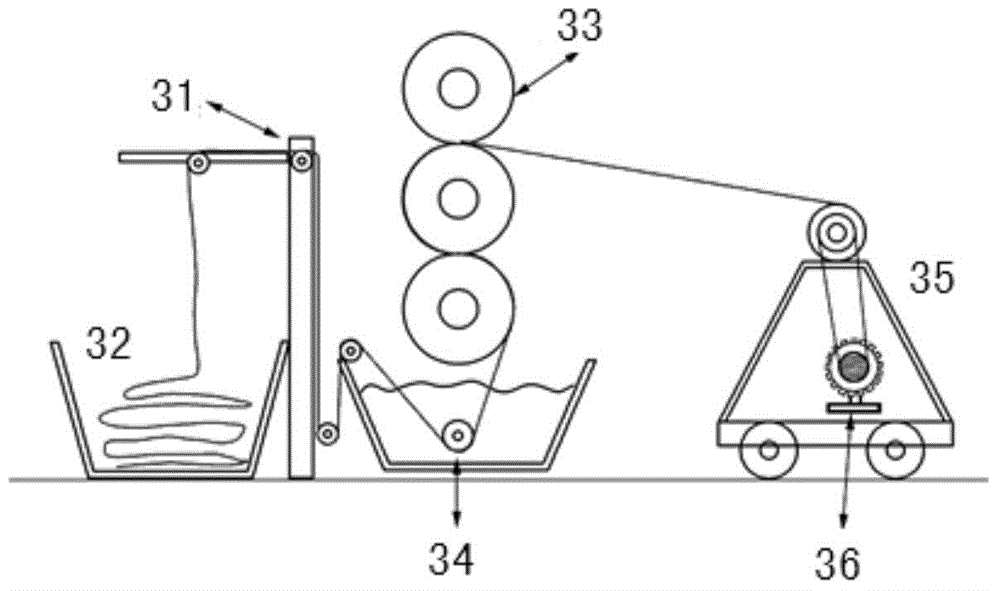

[0029] The technical solution of the present invention will be further described in conjunction with the accompanying drawings and embodiments, which is believed to be clear to those skilled in the art.

[0030] The double-sided napping process steps are as follows:

[0031] (1) Send the gray cloth into the high-temperature and high-pressure setting machine for the first pre-setting. The parameters of the high-temperature and high-pressure setting machine are set to a width of 145CM, a weight of 285G / ㎡, and a temperature of 180°C;

[0032] (2) After the pre-setting is completed, the gray cloth is sent to the cold pile machine for degreasing processing and chemical foaming treatment. The cold pile machine first fully soaks the gray cloth in water, and some chemical additives are added to the water, including fluffing agent, degreasing agent, etc. Agent, antistatic injection, silicone oil, softener, after soaking completely, seal the gray cloth under the condition of water, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com