Rapid repair tower system and its erection method

A technology for repairing towers and towers, which is applied to towers, building types, buildings, etc., can solve problems such as power interruptions and delays in repairing time, and achieve the effects of improving installation efficiency, reducing costs, and facilitating transportation and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

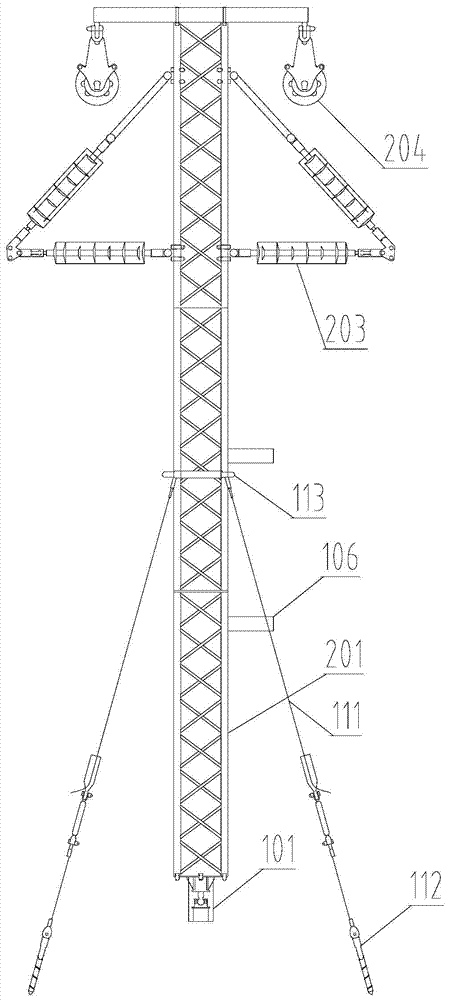

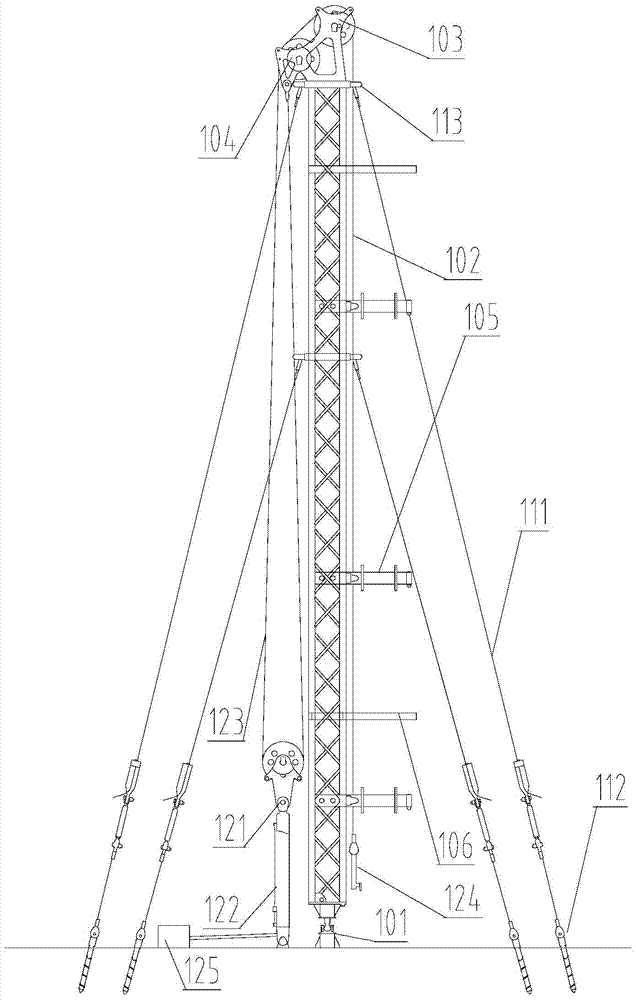

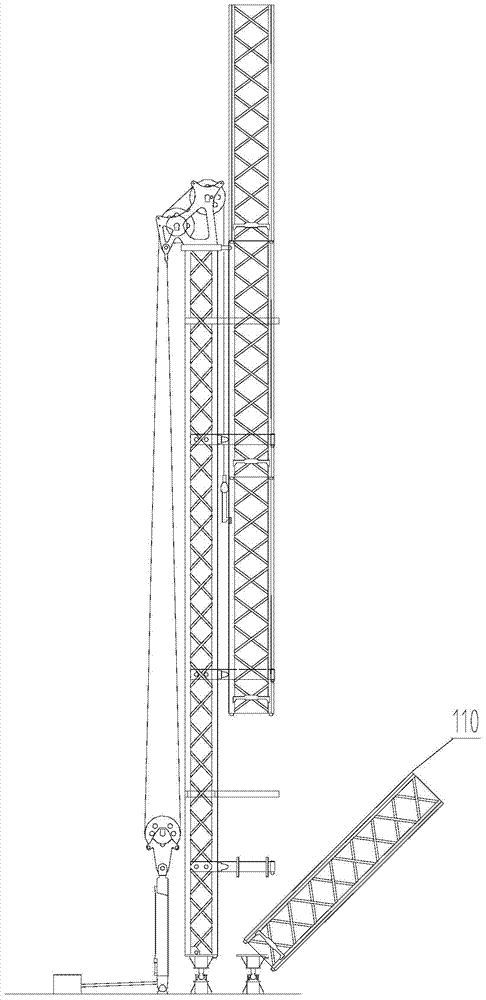

[0055] Example 1, please refer to Figure 1 to Figure 6

[0056] Such as Figure 1 to Figure 6 A quick repair tower system shown includes two bases 101, a repair tower and a lifting tower. The base 101 is arranged on a bottom plate fixed to the ground, and the repair tower and the lifting tower are respectively arranged on the two bases 101 In order to make the repair tower and the lifting tower and the base 101 more stable, in this embodiment, a support platform is provided under the repair tower and the lifting tower. The support platform is set on the base 101, and the support platform and the base 101 is fixedly connected, and the emergency repair tower and the lifting tower are vertically arranged on the supporting platform.

[0057] The repair tower includes a repair tower body 201, which includes a plurality of standard sections 110, a tower top hanger 204, and an insulator seat 203 connected in sequence, and the lower ends of the plurality of standard sections 110 connect...

Embodiment 2

[0089] Example 2, please refer to Figure 7 with Figure 8

[0090] The basic structure and principle of the rapid repair tower system provided in this embodiment and the technical effects produced are the same as those of the first embodiment. For a brief description, for the parts not mentioned in this embodiment, please refer to the corresponding content in the first embodiment.

[0091] The rapid repair tower system obtained through the above design can basically meet its normal use, but in the purpose of further improving its functions, the designer has further improved the rapid repair tower system.

[0092] The difference between this embodiment and Embodiment 1 is that the anchor cable device in this embodiment avoids the situation of insufficient pre-tightening force between the standard sections 110 when the anchor cable connecting frame 113 is fixed at the connection between the standard sections 110.

[0093] Further, the realization of the above-mentioned functions is real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com