Using method of high-position air (vapor) suction device

An aspirator, a high-level technology, applied in the direction of machine operation, machine/engine, and machines that use refrigerant evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

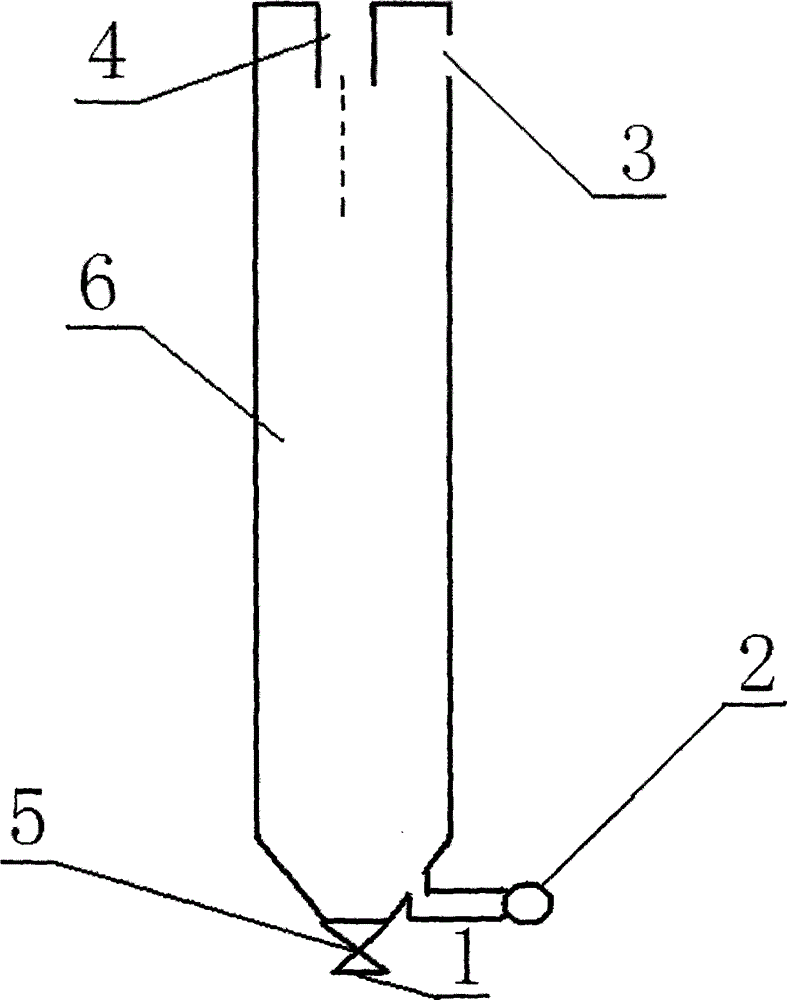

[0013] Test one: if figure 1 As shown, the high-level aspirator includes a water turbine inlet 1, a pressure gauge 2, an air inlet 3, a water inlet 4, a valve 5, and a main pipe 6 with a diameter of 20mm.

[0014] The water inlet 4 has a diameter of 5mm and an outlet diameter of 8mm;

[0015] Standard: Water in the air inlet 3 shall prevail (no flow out);

[0016] The vertical height of water vapor flowing in the pipeline (see the table below)

[0017] height (m) 1 2 3 Pressure (mPa) 0.023 0.028 0.033

[0018] The air inlet 3 shall not be smaller than the area of the main pipe;

[0019] The port of the pressure gauge faces upward;

[0020] The main pipe must be vertical, otherwise it will affect the effect.

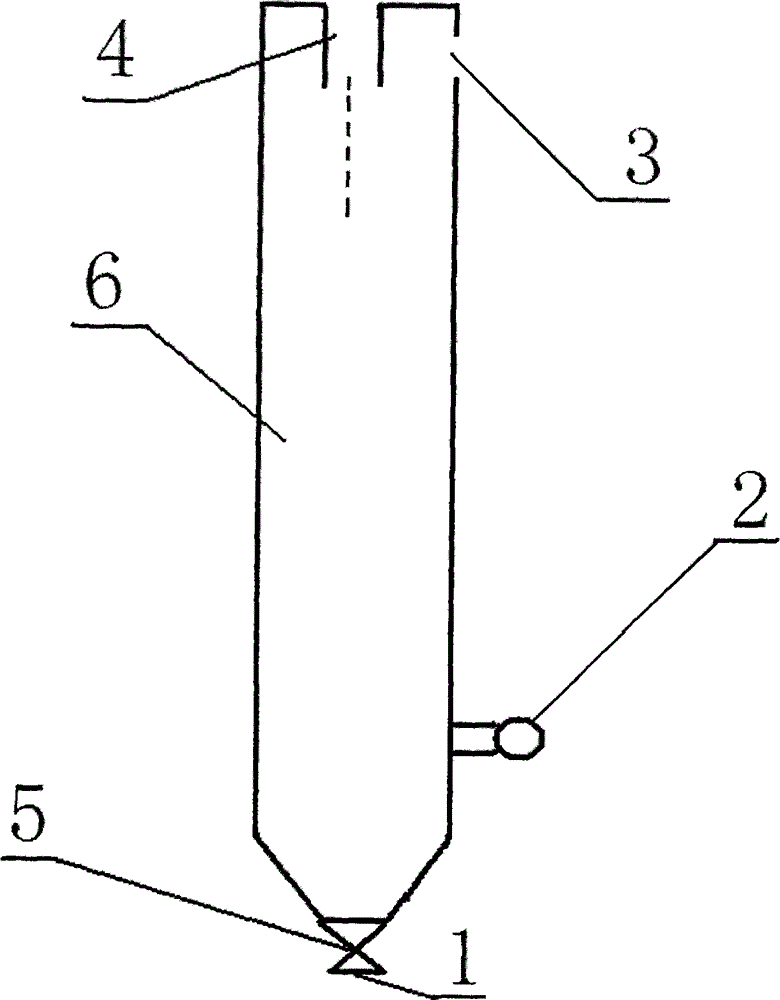

[0021] Test two: if figure 2 As shown, the high-level aspirator includes a water turbine inlet 1, a pressure gauge 2, an air inlet 3, a water inlet 4, a valve 5, and a main pipe 6 with a diameter of 20 mm.

[0022] The water inlet 4 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com