Large-sized low lift head pump device energy performance calculation method

A low-lift pump, large-scale technology, used in pump control, non-variable-capacity pumps, machines/engines, etc., can solve the problems of high cost, long cycle, affecting the design quality of pump devices, and the construction progress of pump station projects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

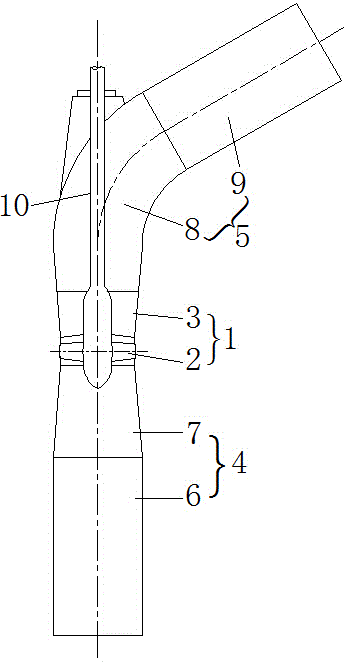

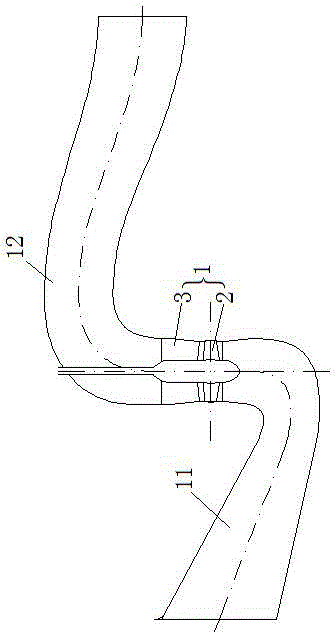

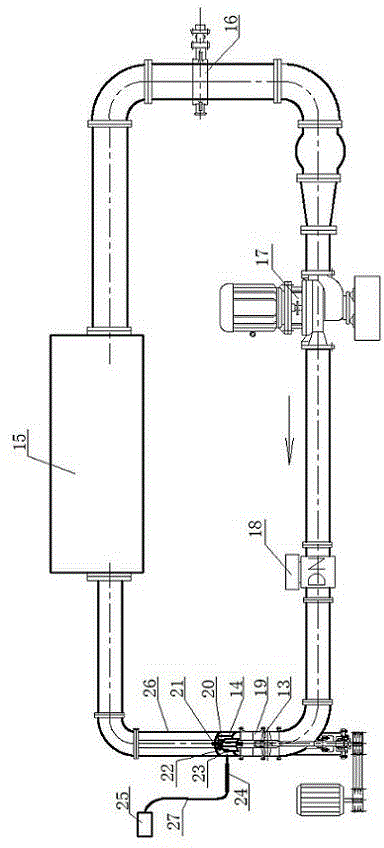

[0065] The design flow rate of the large-scale low-lift pumping station in this embodiment is 100m 3 / s, the design head and average head are 3.86m and 3.66m respectively, adopt low-lift vertical pump device, choose 4 sets of 3.15ZLQ-4 vertical axial flow pumps (one of which is spare), and use TJ04-ZL-06 The water pump model adopts an elbow-shaped water inlet channel and a low hump-shaped water outlet channel. The schematic diagram of the pump device is shown in figure 2 The steps of applying the present invention to calculate the energy performance of the station pump device are as follows:

[0066] (1) The hydraulic performance test data of the water pump model TJ04-ZL-06 blade placement angles of -4°, -2°, 0°, +2° and +4° issued by the testing agency are listed in the table 1; Q in Table 1 bm 、H bm and η bm represent the flow rate, head and efficiency of the pump model respectively;

[0067] (2) The hydraulic performance test data for the blade placement angle of -4° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com