A kind of high temperature resistant synchronous belt and its preparation method

A timing belt, high temperature resistant technology, applied in belts, transmission belts, mechanical equipment, etc., can solve the problem of inability to manufacture timing belts, increase physical crosslinking density and interface bonding performance, improve mechanical properties and high temperature resistance performance , the effect of high cohesion and polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

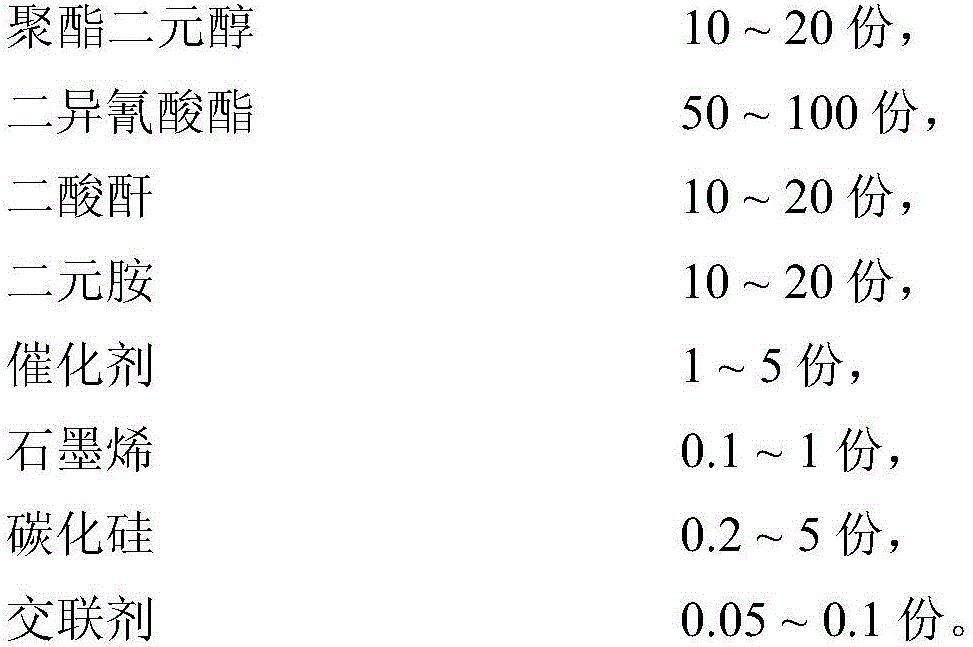

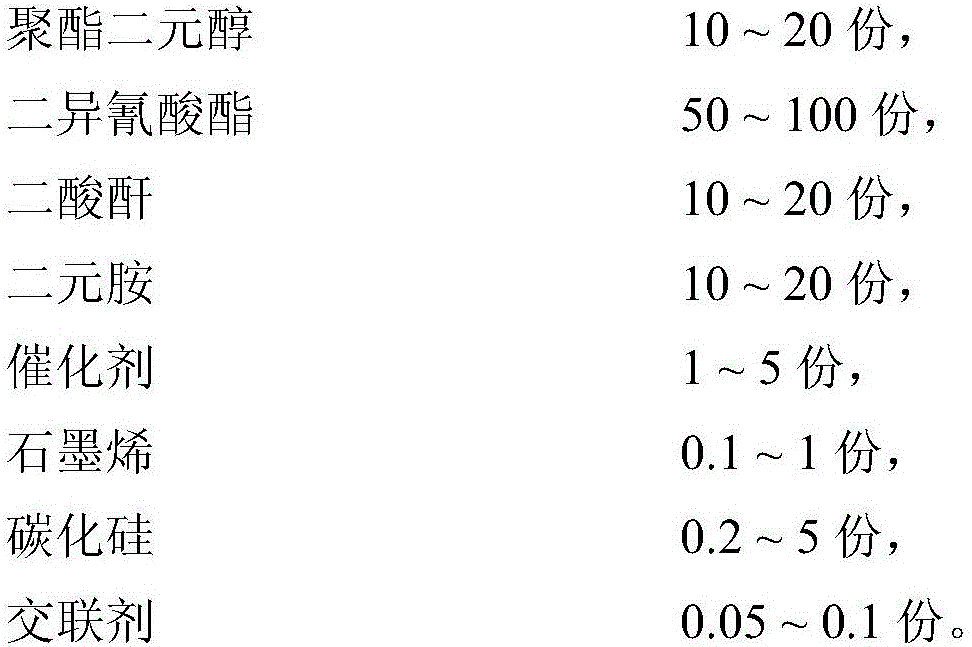

[0049] The high-temperature-resistant synchronous belt of this embodiment includes a synchronous belt skeleton and a rubber compound coated on the outside of the synchronous belt skeleton. The raw materials of the rubber compound include the following components by weight:

[0050]

[0051]

[0052] The preparation method of the above-mentioned high temperature resistant synchronous belt comprises the following steps:

[0053] (1) Preparation of synchronous belt skeleton

[0054] The polyacrylonitrile-graphene oxide fiber and polyacrylonitrile fiber are spun through the processes of blowing, carding, pre-doubling, sliver coiling, combing, head-doubling, two-doubling and three-doubling in sequence according to the weight ratio of 3:7. said skeleton yarn;

[0055] Apply a layer of silicone oil evenly on the mould, then put the corresponding cloth cover on the mould, and hoist it on the forming host; lead out 2 S-twisted and 2 Z-twisted skeleton yarns from the tensioner re...

Embodiment 2

[0070] The high-temperature-resistant synchronous belt of this embodiment includes a synchronous belt skeleton and a rubber compound coated on the outside of the synchronous belt skeleton. The raw materials of the rubber compound include the following components by weight:

[0071]

[0072] The preparation method of the above-mentioned high temperature resistant synchronous belt comprises the following steps:

[0073] (1) Preparation of synchronous belt skeleton

[0074] The polyacrylonitrile-graphene oxide fiber and polyacrylonitrile fiber are spun through the processes of blowing, carding, pre-doubling, sliver coiling, combing, head-doubling, two-doubling and three-doubling in sequence according to the weight ratio of 3:7. said skeleton yarn;

[0075] Apply a layer of silicone oil evenly on the mould, then put the corresponding cloth cover on the mould, and hoist it on the forming host; lead out 2 S-twisted and 2 Z-twisted skeleton yarns from the tensioner respectively, ...

Embodiment 3

[0082] The high-temperature-resistant synchronous belt of this embodiment includes a synchronous belt skeleton and a rubber compound coated on the outside of the synchronous belt skeleton. The raw materials of the rubber compound include the following components by weight:

[0083]

[0084] The preparation method of the above-mentioned high temperature resistant synchronous belt comprises the following steps:

[0085](1) Preparation of synchronous belt skeleton

[0086] The polyacrylonitrile-graphene oxide fiber and polyacrylonitrile fiber are spun through the processes of blowing, carding, pre-doubling, sliver coiling, combing, head-doubling, two-doubling and three-doubling in sequence according to the weight ratio of 3:7. said skeleton yarn;

[0087] Apply a layer of silicone oil evenly on the mould, then put the corresponding cloth cover on the mould, and hoist it on the forming host; lead out 2 S-twisted and 2 Z-twisted skeleton yarns from the tensioner respectively, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com