Heat transfer oil large-scale negative pressure short-circuit circulation system and circulation method

A circulation system and heat-conducting oil technology, applied in heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as unstable quality of calcined coke products, large safety hazards, and large pressure fluctuations, so as to eliminate Pipeline oil injection phenomenon, high safety and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

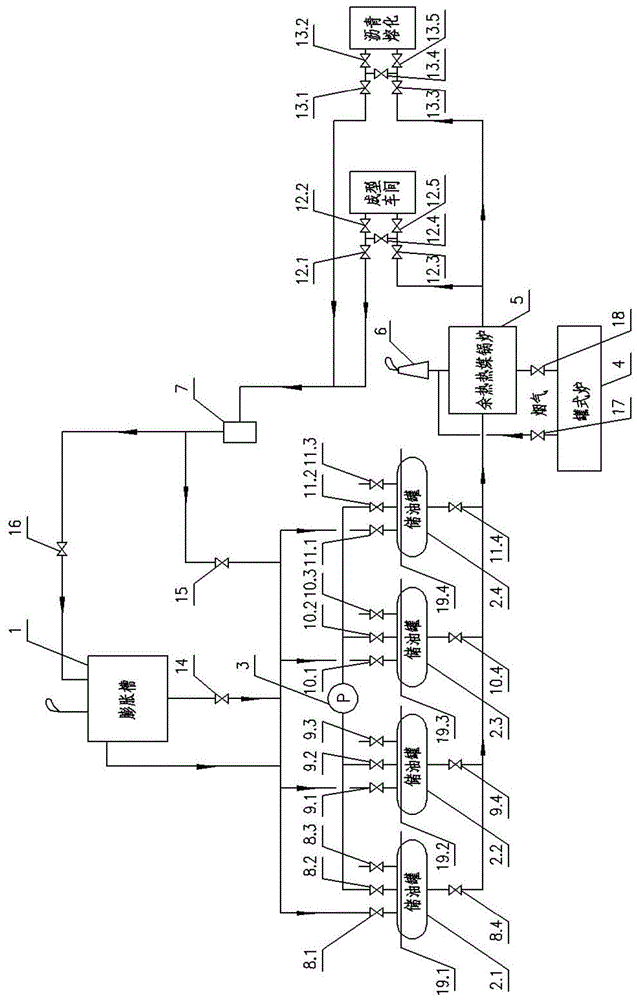

[0029] The heat transfer oil large-scale negative pressure short-circuit circulation system of the present invention is provided with an expansion tank, an oil storage tank, an oil-gas separator, and a waste heat heat medium boiler. The inlet of the expansion tank communicates with the oil-gas separator, and the outlet of the expansion tank communicates with the oil storage tank. Through the oil inlet main pipe, the oil return main pipe of the oil storage tank is connected with the waste heat heat medium boiler, and the outlet of the waste heat heat medium boiler is respectively connected with the oil inlet pipe of the oil use part (such as: molding workshop, asphalt melting workshop, etc.), and the oil use part The oil return pipe communicates with the oil-gas separator. in,

[0030] The oil storage tank is connected by four branch pipes, one of which is connected to the oil outlet of the expansion tank and the oil inlet of the oil storage tank, with a quick cut valve in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com