Stepping CNC system, generating method of machining file, and real-time control method

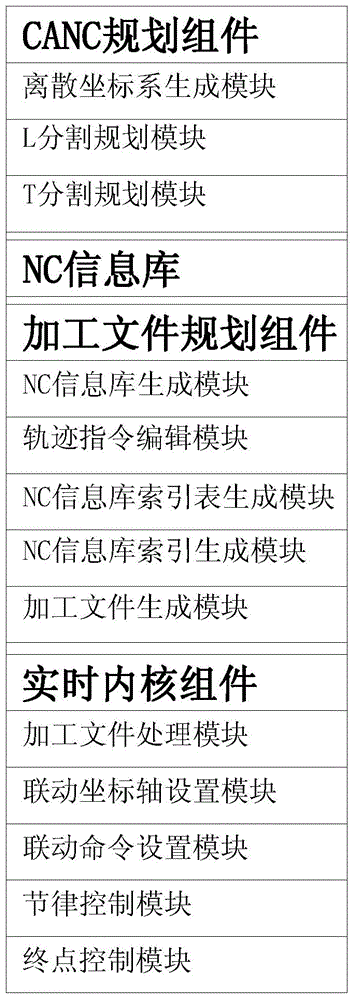

A processing file and step-by-step technology, which is applied in the step-by-step computer numerical control system and the generation of processing files, can solve the problems affecting the processing speed and processing quality of the CNC system, and achieve saving storage space and simple control of time , The effect of increasing the printing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

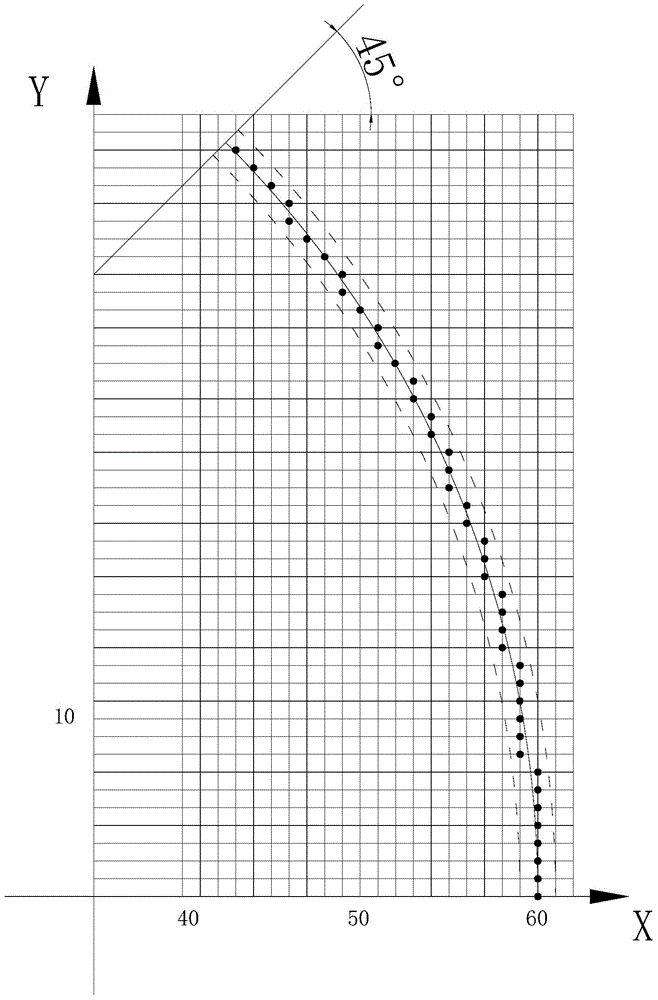

[0214] There are only two kinds of digital images for any curve, that is, microscopic digital images and incremental digital images. Correspondingly, the relevant coordinate axes feed a discrete equivalent or several discrete equivalents.

[0215] The discrete feed information of the former coordinate axis is a stepping pulse in the form of "0" and "1", and its CNC system is called a stepping CNC system. The latter's coordinate axis discrete feed information is a coordinate value increment, and its CNC system is called an incremental CNC system.

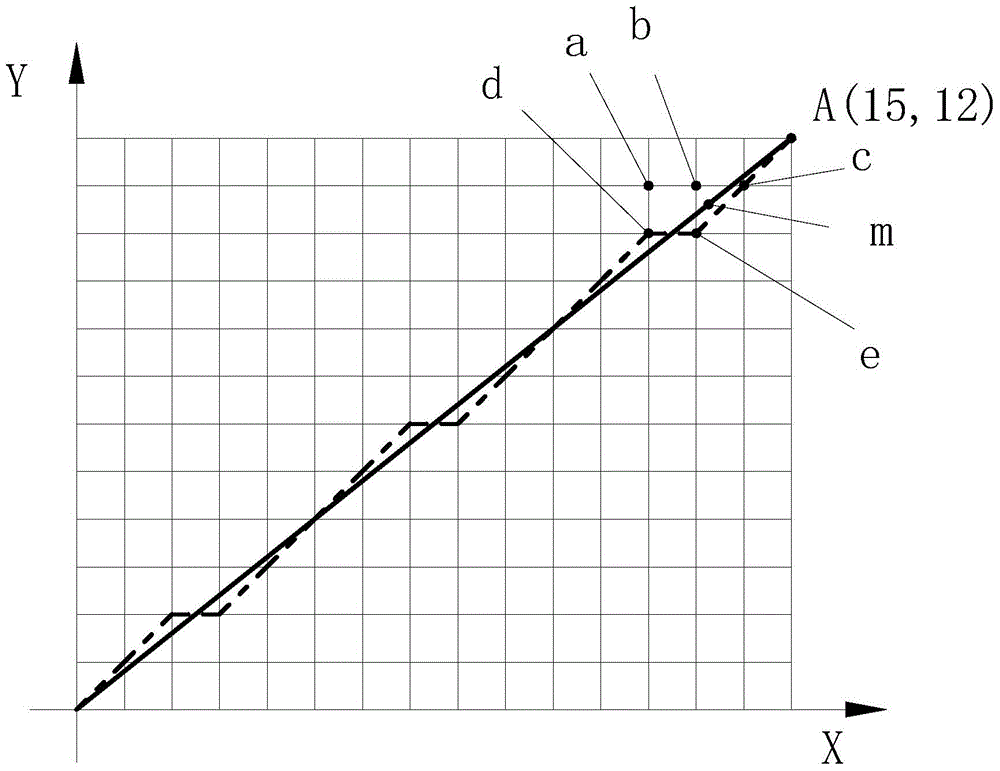

[0216] The pre-set discrete error is called the discrete scale, denoted as e. The coordinate axes are discretized on a discrete scale, and the coordinate plane is gridded by parallel lines whose distance from each other is the discrete scale. The coordinate system thus established is called a discrete coordinate system.

[0217] discrete scale e x ,...,e y is the system parameter of the discrete coordinate system. The discrete s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com