Snow blowing and ice melting trolley for high voltage equipment

A technology of high-voltage equipment and trolleys, which is applied in the direction of switchgear, electrical components, chemical instruments and methods, etc., and can solve problems such as potential safety hazards, damage to porcelain bottles, and poor results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

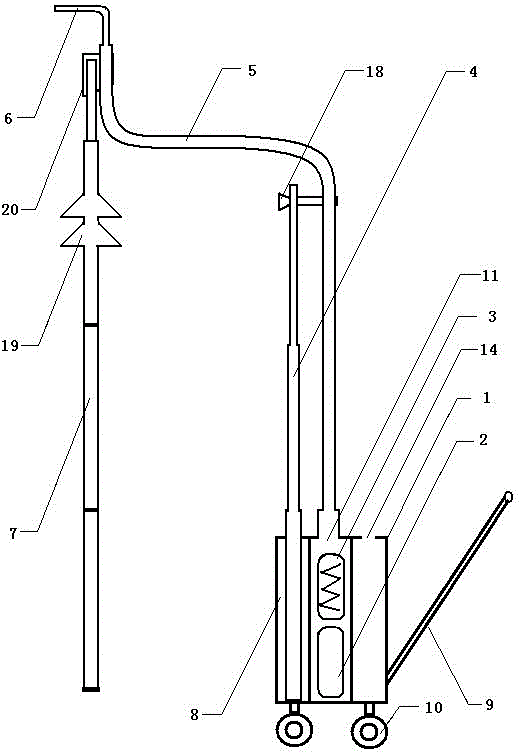

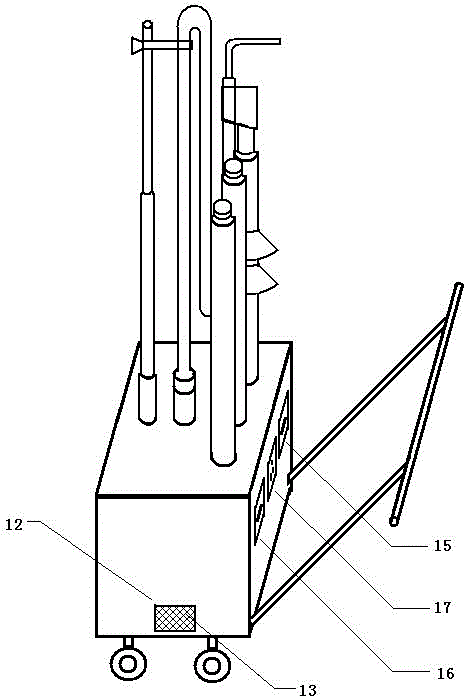

[0010] Such as figure 1 , figure 2 As shown, the present invention includes a trolley (1), an air compressor (2), a heater (3), a support rod (4), an air pipe (5), a mouthpiece (6) and an operating rod (7), and the air The compressor (2) and the heater (3) are installed in the trolley (1), the trolley (1) is connected to the lower end of the ventilation pipe (5), the upper end of the ventilation pipe (5) is connected to the mouthpiece (6), and the ventilation pipe ( 5) An operating rod (7) is connected to the upper part, a support rod (4) is connected to the middle part of the air pipe (5), and the support rod (4) is fixed on the cart (1). Cart (1) comprises car body (8), wheel (10) and handlebar (9), and car body (8) is cuboid, has four wheels (10) below car body (8), and car body (8) The rear side of the handlebar (9) is connected. The interior of the car body (8) is divided longitudinally by partitions into several intervals, one of which is equipped with an air compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com