An automatic seeding method and device for a tobacco seedling raising machine

The technology of a seeding device and a seedling raising machine, which is applied in the field of agricultural machinery, can solve the problems of tobacco farmers such as high labor intensity, low efficiency, and inability to meet the large-scale seedling raising of tobacco leaves, and achieve the effect of improving tobacco seeding efficiency and rapid seeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

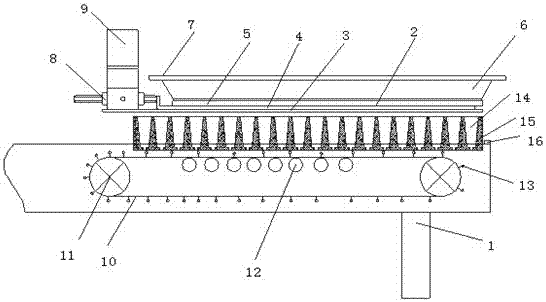

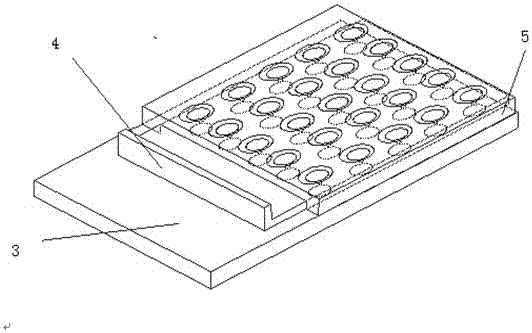

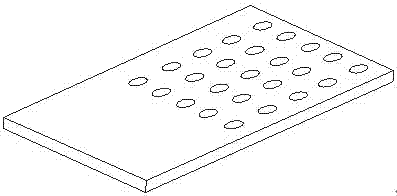

[0031] like figure 1 , 2 As shown, an automatic seeding device of a tobacco seedling raising machine includes: a frame 1, a seeding mechanism 2, a conveying mechanism, a supporting roller 12, and an electric control system 9. Plate 3, sub-seed plate 4, sub-seed upper plate 5, seed hopper 6, cover plate 7, a small motor 8 is installed on one side of the sowing plate 3, the small motor 8 is fixed on the frame, and the small motor is installed directly above Electric control system 9, one end of the small motor shaft is fixedly connected with the seed plate 4; a group of supporting rollers 12 are arranged directly below the sowing mechanism, and the two ends of the supporting rollers 12 are fixed on the left and right beams of the frame. The upper surface is lower than the A face of the chain; the conveying mechanism is a chain 10 and a sprocket 11 meshing transmission, and a plurality of conveying push bars 13 are installed on the chain 10, and the transmission force of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com