Water-jet scallop adductor muscle separating device

A peeling equipment and water jet technology, applied in the field of water jet shell column peeling device, can solve the problems of incomplete shell column and viscera peeling, reduced work efficiency, harsh labor environment, etc., to facilitate subsequent processing operations, improve work efficiency, The effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

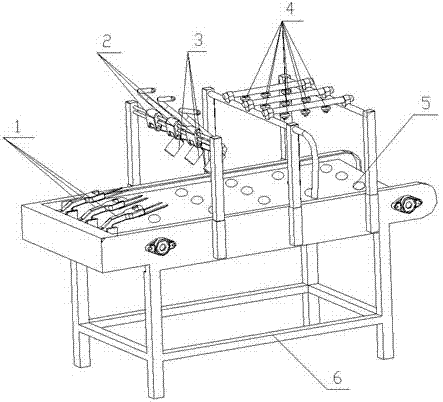

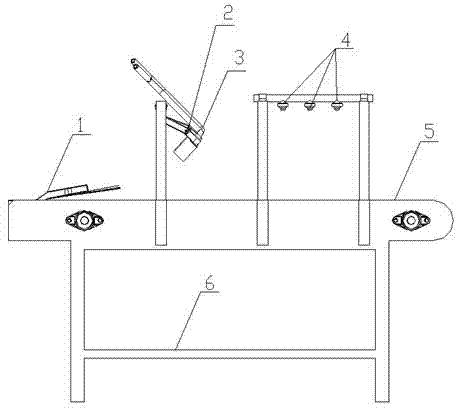

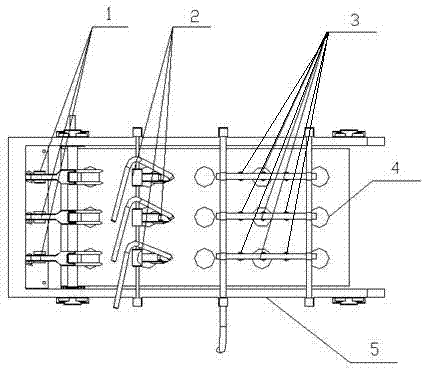

[0013] see figure 1 , figure 2 , image 3 As shown, the present invention consists of a clamping fixture (1), an angle adjustment mechanism (2), a stripping nozzle (3), a cleaning nozzle (4), a conveyor belt (5), and a bracket (6), wherein the clamping fixture ( 1), the angle adjustment mechanism (2), the peeling nozzle (3), the cleaning nozzle (4), and the conveyor belt (5) are all installed on the bracket (6), and the scallops are placed on the conveyor belt (4) and transported by the conveyor belt (4) , the scallop is cleaned by the cleaning nozzle (3), and then enters the peeling area, and is clamped by the clamping fixture (1). After the scallop is clamped, the peeling nozzle (2) sprays high-speed water to peel the shell .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com