pt/α‑moc 1‑x Supported Catalyst and Its Synthesis and Application

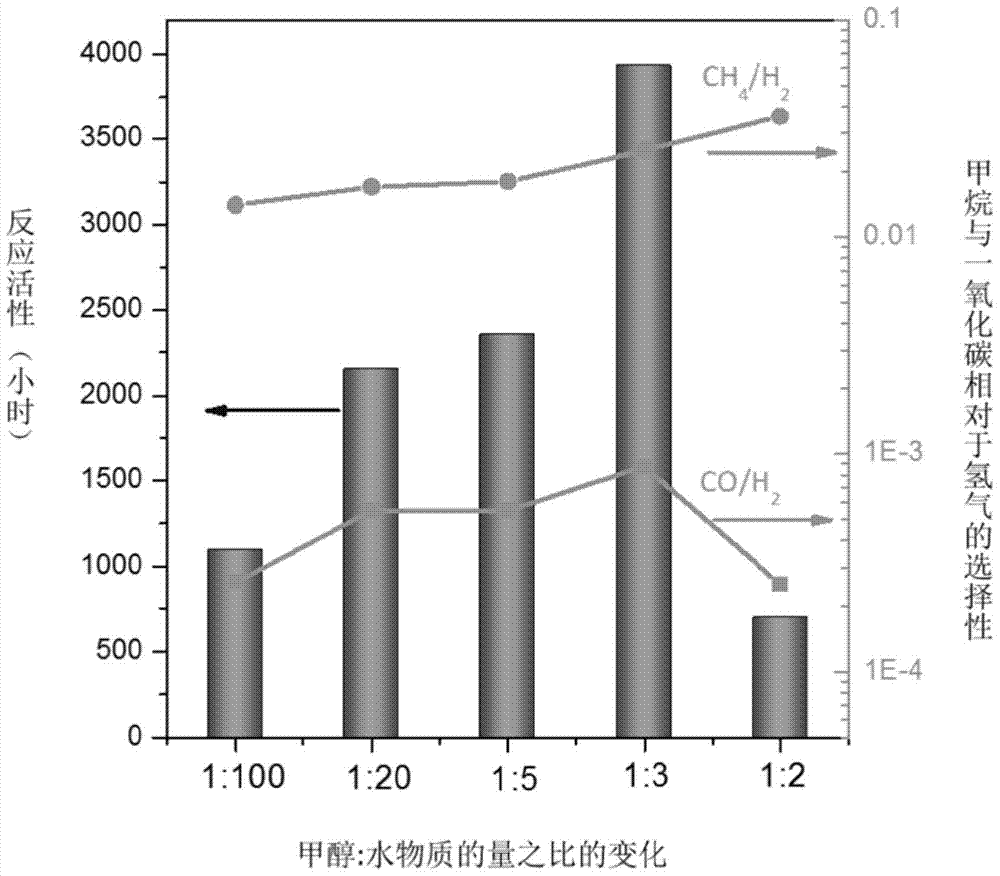

The technology of a supported catalyst and a synthesis method, applied in the field of catalysis, can solve the problems of inability to exist stably, the activity of noble metal catalysts is low, and does not meet the requirements of use, and achieves the effects of inhibiting methanol decomposition reaction, improving coverage and wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

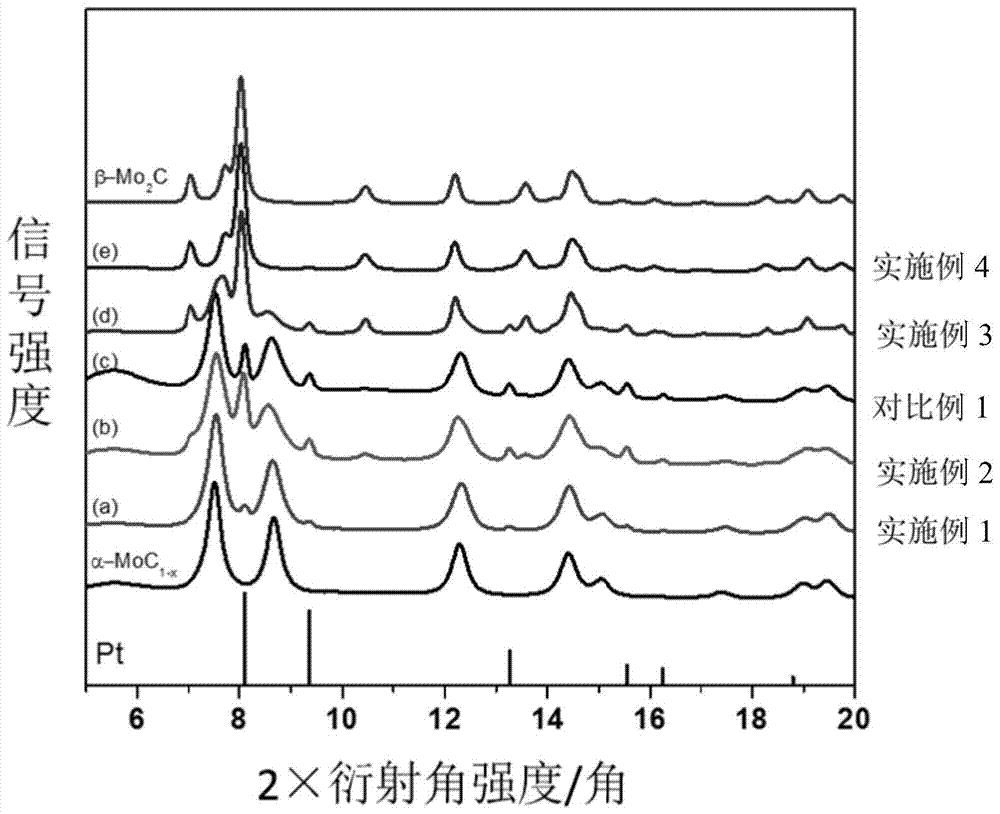

[0032] Example 1Pt / α-MoC 1-x Synthesis of (100% α) catalyst (MoO 3 200nm)

[0033] Dissolve 1 g of the platinum precursor salt chloroplatinic acid hexahydrate in 10 mL of water, soak in H 2 PtCl 6 solution to MoO 3 on the carrier, stirred at room temperature until dry, and then dried in a vacuum oven at 60°C, then placed the catalyst in a muffle furnace for calcination, and programmed the temperature to 500°C and kept it for 120min. Last at 20% CH 4 / H 2 The carbonization temperature was programmed to 700°C in an atmosphere and kept for 120min.

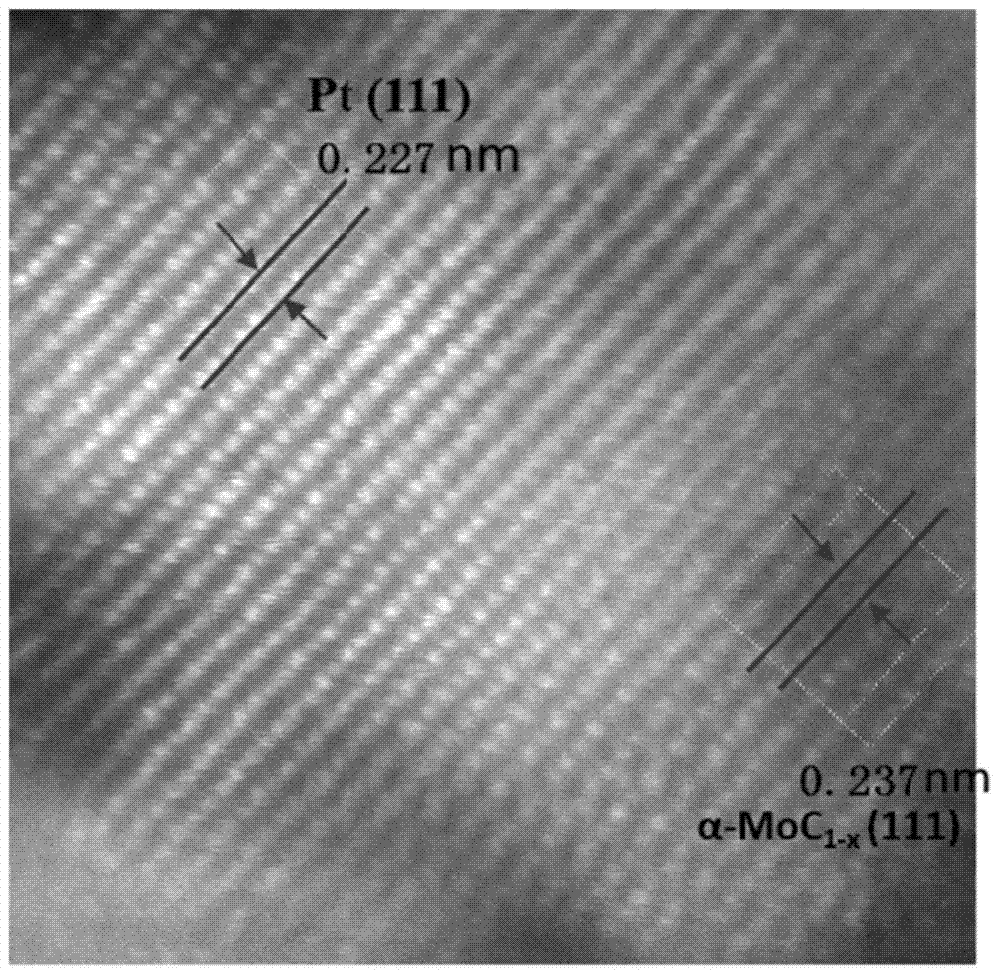

[0034] Pt / α-MoC synthesized by the present invention 1-x The morphology of supported catalysts was observed by dark field scanning transmission mode of transmission electron microscope, and the bulk phase structure was observed by X-ray diffractometer (XRD).

[0035] The XRD sample preparation method is as follows: the above carbonized catalyst was treated with 0.5% O 2 / Ar passivation gas passivation 8h, can be used for XRD t...

Embodiment 2

[0040] Example 2Pt / MoC x Synthesis of (70%α)

[0041] Dissolve 1 g of the platinum precursor salt chloroplatinic acid hexahydrate in 10 mL of water, soak in H 2 PtCl 6 solution, stirred at room temperature until dry, then dried in a vacuum oven at 60°C, in 20% CH 4 / H 2 The carbonization temperature was programmed to 700°C in an atmosphere and kept for 120min. XRD picture as shown figure 1 (c) shown.

Embodiment 3

[0042] Example 3Pt / MoC x Synthesis of (45%α)

[0043] Dissolve 1g of ammonium heptamolybdate in 10mL of deionized water, stir until completely dissolved, dissolve 1g of the platinum precursor salt chloroplatinic acid hexahydrate in 10mL of water, take the aqueous solution of chloroplatinic acid and add it to the ammonium molybdate solution, stir for 2h until precipitation completely, evaporated to dryness in an oil bath at 100°C, ground it and placed it in an oven at 60°C for 3 hours, and then the catalyst was heated in 20% CH 4 / H 2 carbonized in an atmosphere, the temperature was programmed to 700°C and kept for 120min. XRD picture as shown figure 1 (d) shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com