Novel hydraulic correction device

A correction device, hydraulic technology, which is applied in the field of new hydraulic correction devices, can solve the problems of low operation precision, large equipment investment, deformation of metal materials, etc., and achieve the effects of reducing labor intensity, stable operation and improving operation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

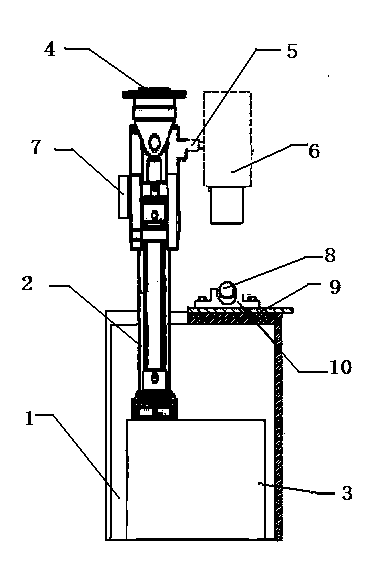

[0011] This embodiment provides a new type of hydraulic correction device, which is characterized in that: the new type of hydraulic correction device includes a body (1), a hydraulic drive cylinder (2), an oil storage tank (3), a hydraulic piston (4), Connecting rod (5), jack (6), pressure gauge (7), deformed workpiece (8), worktable (9), positioning seat (10);

[0012] Among them: an oil storage tank (3) is arranged under the body (1), the oil storage tank (3) is connected to the hydraulic drive cylinder (2), and the hydraulic piston (4) in the hydraulic drive cylinder (2) is connected to the jack through the connecting rod (5) (6), a pressure gauge (7) is provided on one side of the hydraulic drive cylinder (2), a positioning seat (10) is provided on one side of the body (1), and a workbench (9) is provided on the positioning seat (10) to work The table (9) can be placed on the deformed workpiece (8).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com