Device for turning eccentric circle by profiling

A technology of profiling turning and eccentric circle, which is applied in the direction of turning equipment, turning equipment, copying process control system, etc., and can solve the problems of reducing the precision of machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

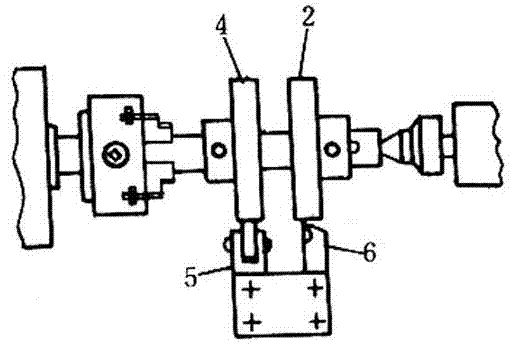

[0010] Combine below figure 1 , to further illustrate the present invention.

[0011] like figure 1 As shown, the present invention relates to a kind of device of profile turning eccentric circle, comprising lathe, profile 4, and its described profile is detachably fixedly connected on the chuck of lathe, the roller 5 of the tool rest of described lathe and When processing the workpiece 2, the roller of the tool holder of the lathe is attached to the outer edge of the former, one end of the workpiece is attached to the former, and the other end is attached to the tail of the lathe. The top of the seat is close to ensure the fixation of the workpiece during processing.

[0012] It also includes a counterweight fixedly connected to the tool rest of the lathe by a traction rope, so as to ensure that the rollers of the tool rest of the lathe are attached to the outer edge of the form.

[0013] The present invention also relates to a method for turning a workpiece with a device....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com