Lifting logistics car

A logistics vehicle and lifting technology, applied in the field of logistics vehicles, can solve the problems of affecting the service life of logistics vehicles, the difficulty of controlling the weight of materials, and affecting the handling efficiency, so as to save manpower and labor intensity, protect against damage, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

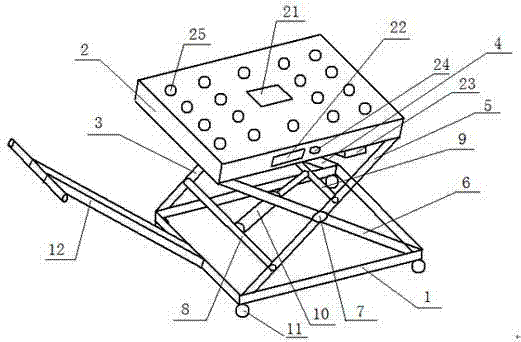

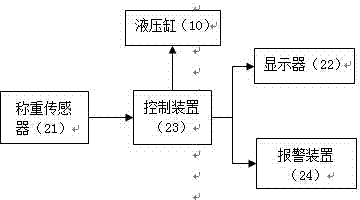

[0025] Such as figure 1 As shown, a lifting logistics vehicle includes a vehicle body and a drawbar 12 hinged to the vehicle body. The vehicle body includes a rectangular bottom frame 1 and a support plate 2 connected to the bottom frame 1 through a support rod. Two long sides of the bottom frame 1 are respectively provided with two hinge points, and the above four hinge points form a square.

[0026] The two hinge points of one long side of the bottom frame 1 are respectively hinged with the support rod A3 and the support rod B4, and the two hinge points of the other long side of the bottom frame 1 are respectively hinged with the support rod C5, the support rod D6, and the support rod A3 And support rod B4, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com