liquid laminar flow processor

A technology of flow processor and liquid layer, applied in the field of liquid laminar flow processor, can solve the problems of liquid material disorder, adverse effect of liquid treatment quality, etc., and achieve the effect of uniform and controllable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

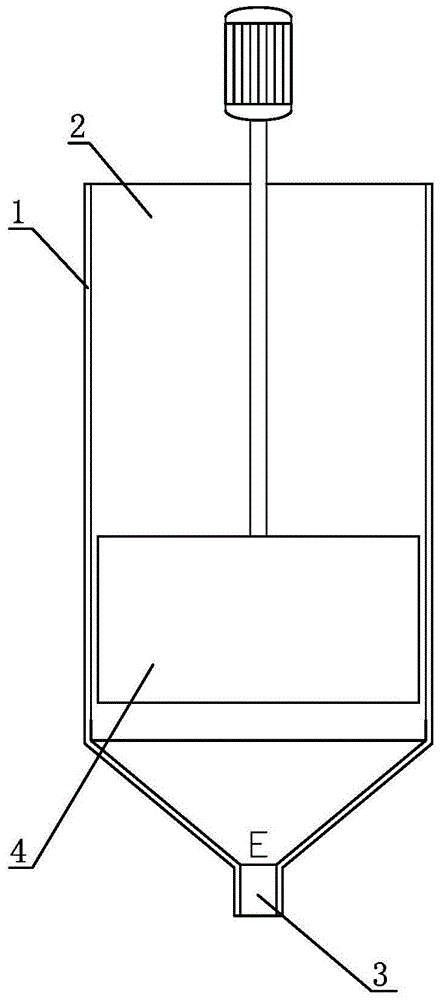

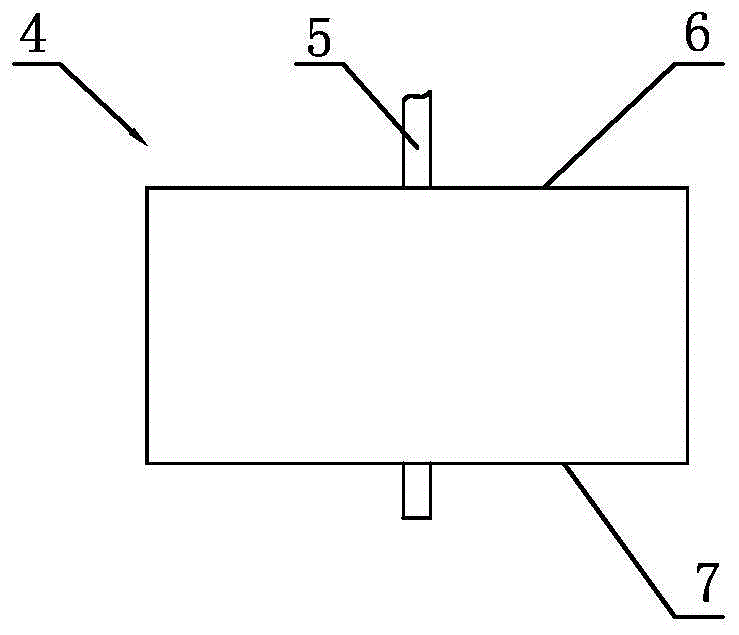

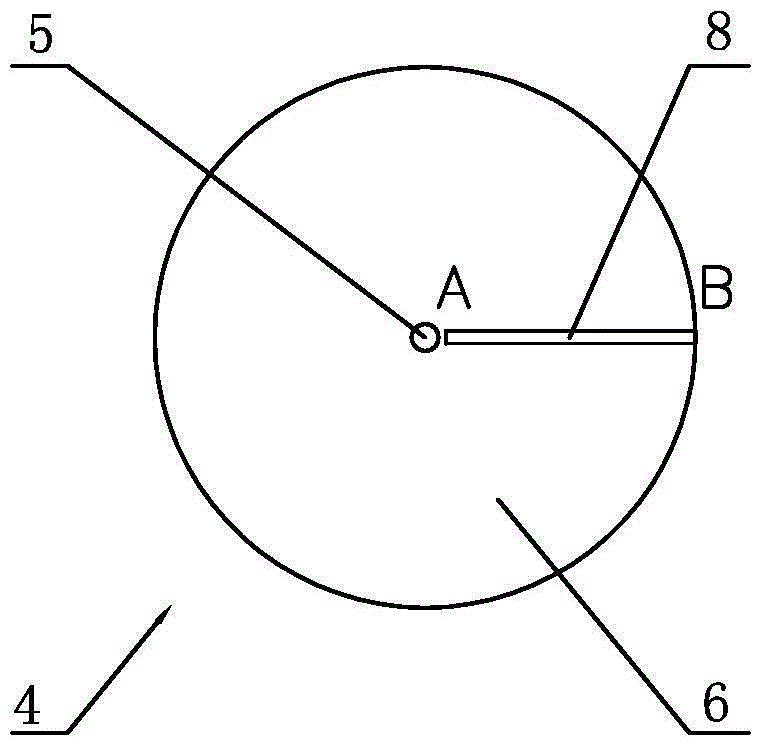

[0025] The first embodiment: as figure 1 As shown, the main body of this liquid laminar flow processor is an upright tank body 1, the tank body 1 is provided with an inlet 2 for filling liquid materials, and an outlet 3 for discharging liquid materials is provided below the tank body 1. The main body of the tank body 1 is a cylinder body, the outlet end of the lower part has a tapered shape with smaller and smaller diameters. This is basically the same as a normal tank. The difference is: the tank body 1 is provided with a cylindrical rotor 4, the outer diameter of the rotor 4 is in rotation with the inner diameter of the tank body 1, and can rotate around the rotating shaft 5 under the driving of the power machine, that is, the motor in the figure. combine figure 2 image 3 It can be seen that the upper end surface 6 of the rotor 4 is provided with a strip-shaped upper opening 8, and the upper end surface 8 extends along a radius of the upper end surface, that is, the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com