Novel belt discharging opening turnover plate device

A flap and belt technology, which is applied in the direction of transportation and packaging, conveyor objects, slideways, etc., can solve the problems of normal production operation, shutdown and flipping of the flap, etc., to meet the requirements of continuous operation, increase leverage, and reduce torque effect of size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

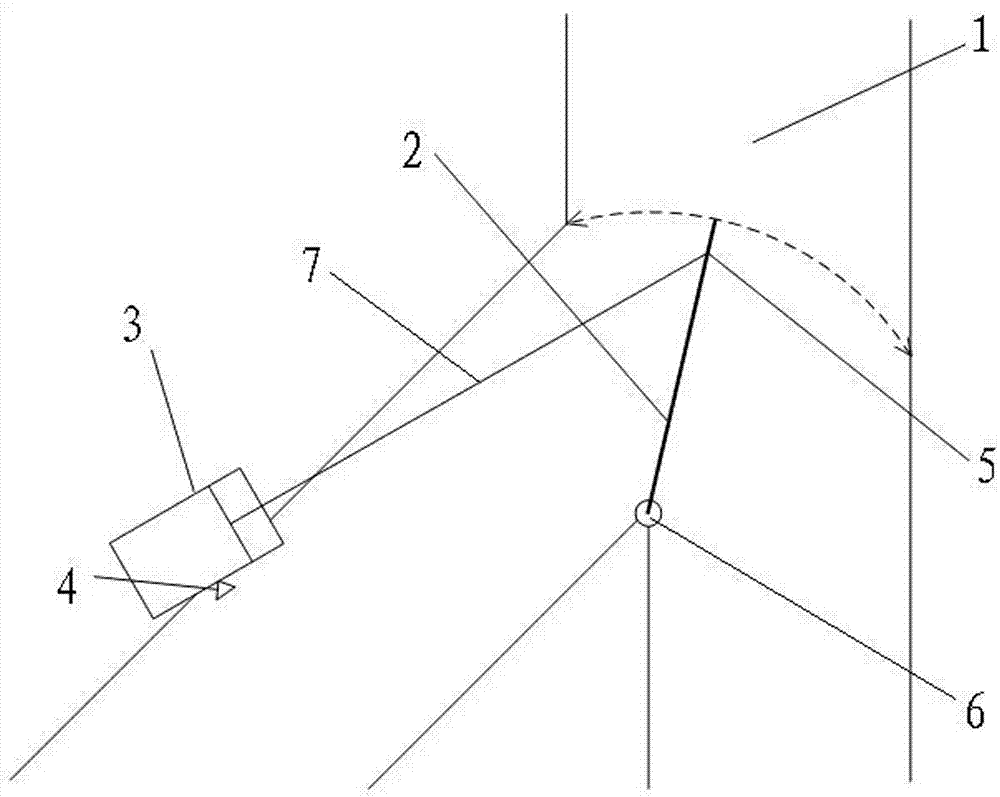

[0014] Such as figure 1 As shown in the figure, a new type of belt discharge port turnover device of the present invention is used to switch between feed bins and processes in sintering production. It includes a turning plate 2 made of wear-resistant steel plate, one end of the turning plate 2 is hinged with a rotating shaft 6, so as to realize flexible rotation when switching between silos and processes. The other end of the turning plate 2 is suspended below the material distribution port 1, and the turning plate 2 rotates clockwise or counterclockwise around the rotating shaft, so as to realize the communication between the material distribution port and the material channel 1 or material channel 2, so as to complete the silo and process switching.

[0015] In order to avoid that the turning plate is not in place when the material is cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com