Step-in type fireproof box self-door-closing system

A fire-proof box and self-closing door technology, which is applied to door/window accessories, fastening devices for wing leaves, buildings, etc., can solve the problem that the automatic release and closing of fire-proof doors is not done well, so as to ensure the explosion-proof and fire-proof performance , the accuracy requirements are reduced, and the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

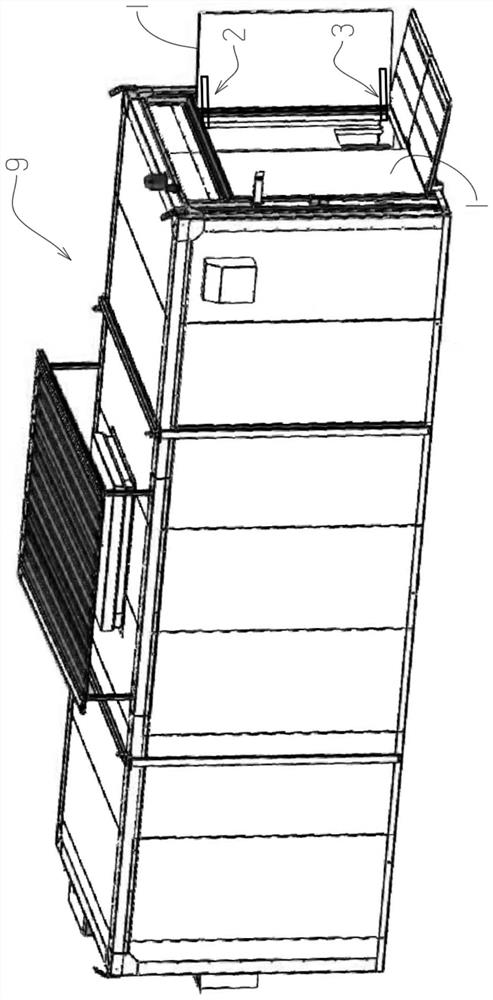

[0038] A walk-in fireproof box self-closing door system, such as figure 1 As shown: the fireproof box 9 is a hazardous chemical storage box for personnel to enter and operate, and the fireproof box is provided with a hinged fireproof door 1,

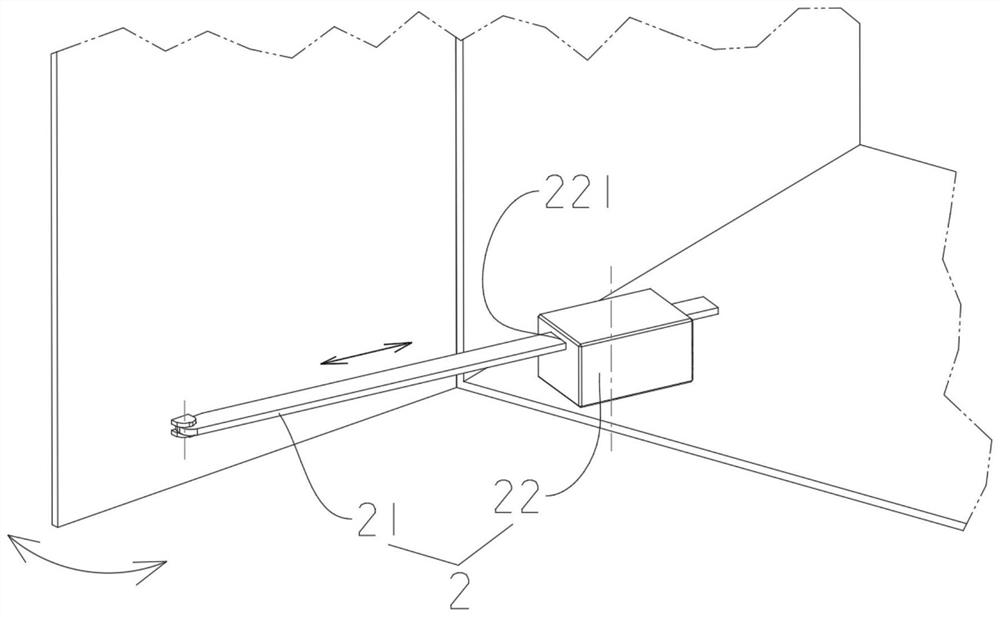

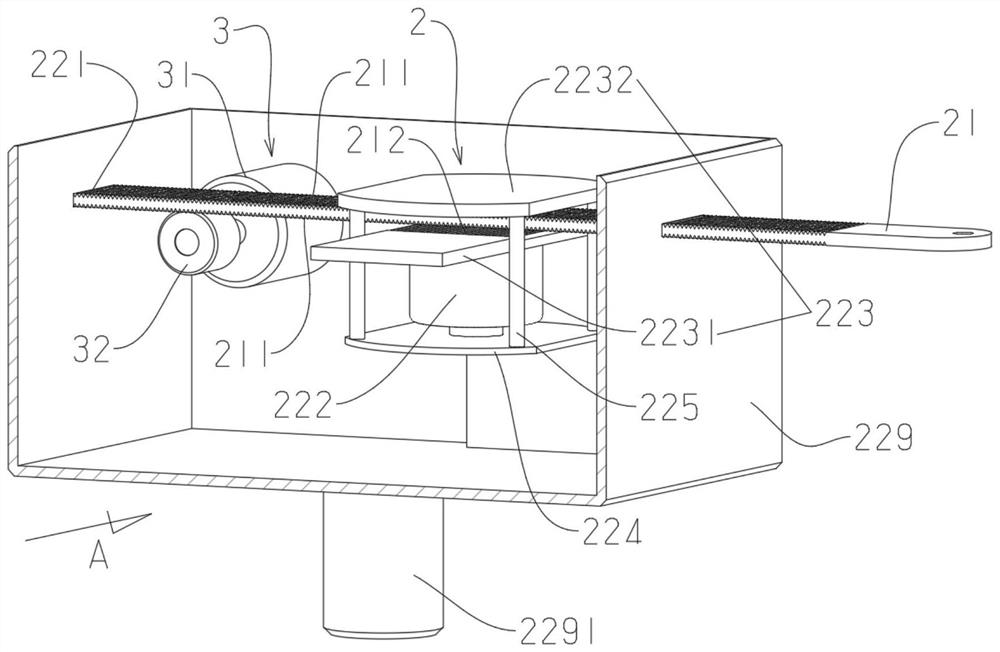

[0039] like Figure 2 to Figure 4 As shown: the self-closing door system includes a door suction device 2 for controlling the opening and closing position of the fire door and a self-closing device 3 for driving the fire door to automatically close;

[0040] The door suction device includes a positioning rod 21 connected to the inside of the fire door and a brake 22 connected to the fire box. One end of the positioning rod is movably connected to the fire door, and the other end passes through the fire door. The connection port 221 of the brake and can slide in the connection port, and the brake is rotatably connected to the fireproof box;

[0041] The brake includes an electromagnetic coil 222 and a brake disc 223, the brake disc incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com