Self-curing insulating and protective material and its manufacturing process

A protective material and manufacturing process technology, which is applied in the field of automatic curing insulating and protective materials, can solve the problems that the gaps of heterosexual parts cannot be effectively filled, easy to loosen, and the sealing effect is not good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This embodiment provides a self-curing insulation protection material, which can provide guarantee for long-term stable and safe power supply, and is widely used in insulation and waterproofing of 10 / 20KV high-voltage overhead bare wires, high-voltage overhead wire fittings leads, and insulation of cross-arms Protection, insulation protection of switch cabinets and substation busbars, and insulation protection of power connectors, knife switches, and isolating switches. At the same time, it can also provide protection for the waterproof sealing of various feeder connectors in communication base stations.

[0023] The material can be extruded as needed, sealed and stored in a vacuum packaging bag. When in use, it can be completely attached to the parts that need insulation protection, without heating, and the air will automatically cure.

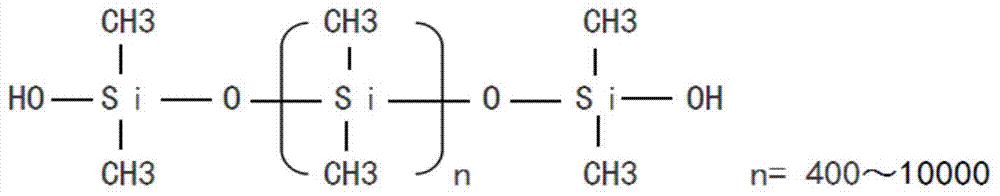

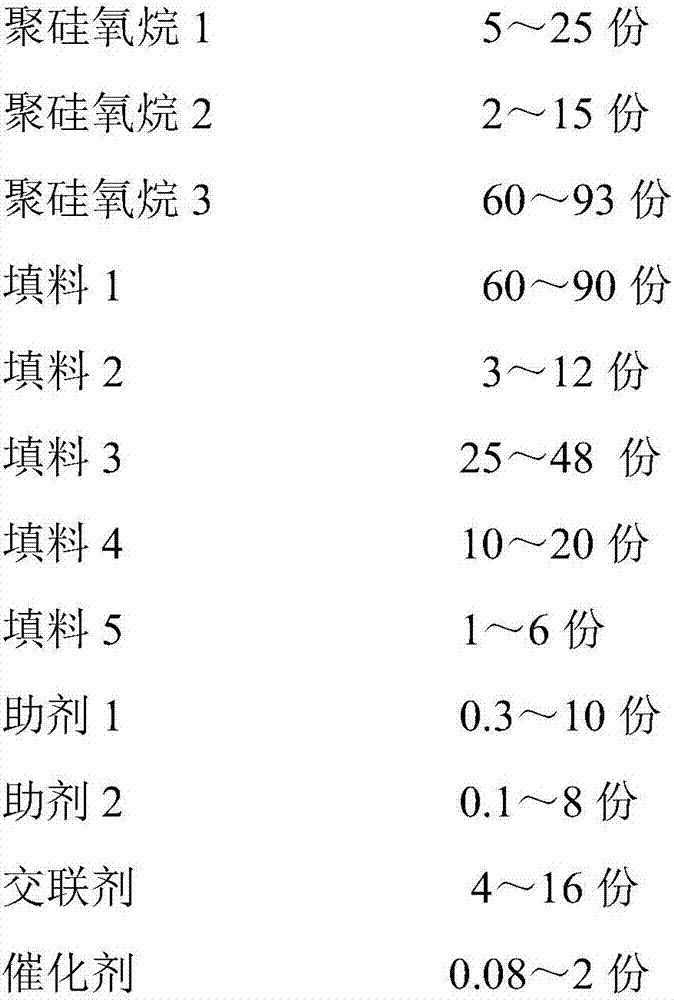

[0024] Among them, the self-curing insulating and protective material includes raw material components and parts: polysiloxane 1: 5-25...

Embodiment 2

[0038] This embodiment provides a manufacturing process for manufacturing the self-curing insulating and protective material in Example 1. When manufacturing the above self-curing insulating and protective material, the following manufacturing process is used:

[0039] Step A: First batching and kneading once, the raw material components and quantities used in the batching are as follows: polysiloxane 1: 5-25 parts, polysiloxane 2: 2-15 parts, polysiloxane 3 : 60-93 parts, Filler 1: 60-90 parts, Filler 2: 3-12 parts, Filler 3: 25-45 parts, Filler 4: 10-20 parts, Filler 5: 1-6 parts, Auxiliary 1: 0.3-10 parts, auxiliary agent 2: 0.1-8 parts, cross-linking agent: 4-16 parts, catalyst: 0.08-2 parts, each part is determined according to the actual finished product output, and the unit of each part can be kilogram.

[0040] Among them, polysiloxane 1 uses one or more polysiloxanes with a viscosity (25°C) of 1500-100000CS; A polysiloxane; Polysiloxane 3 selects one or more polysilo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com