Fluid composition for machining and machining method

A technology of mechanical processing and composition, applied in the direction of lubricating composition, petroleum industry, etc., which can solve the problems of reduced cost-effectiveness of fluids, damage to the useful or effective life of fluids, increased cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

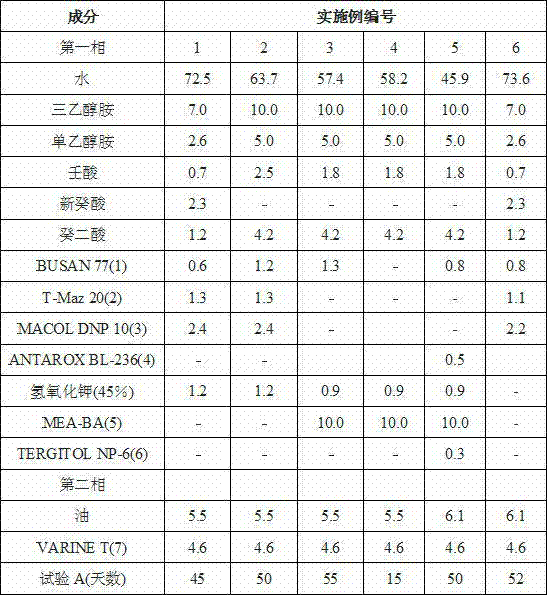

Embodiment 1-6

[0054] (1) BUSAN 77-poly[oxyethylene (dimethylimino) ethylene (dimethylimino) ethylene dichloride], Buckman Laboratories, BUSAN is a registered trademark of Buckman Laboratories

[0055] (2) T-Maz 20 - Ethoxylated sorbitan monolaurate with 20 moles of ethylene oxide, PPG Corp. , T-Maz is PPG Corp. registered trademark of

[0056] (3) MACOL DNP 10-ethoxylated dinonylphenol with 10 moles of ethylene oxide, PPG Corp., MACOL is a registered trademark of PPG Corp.

[0057] (4) ANTAROX BL-236, aliphatic polyether-Rhone, Poulenc, ANTAROX is a registered trademark of Rhone-Poulenc

[0058] (5) MEA-BA, a mixture of 35.7% water, 14.3% monoethanolamine and 50% boric acid (by weight)

[0059](6) TERGITOL NP-6, ethoxylated nonylphenol with 6 moles of ethylene oxide, Union Carbide Corp., TERGITOL is a registered trademark of Union Carbide Corp.

[0060] (7) VARINE T, tall oil hydroxyethyl imidazoline, Sherex Corp., VARINE is a registered trademark of Sherex Corp.

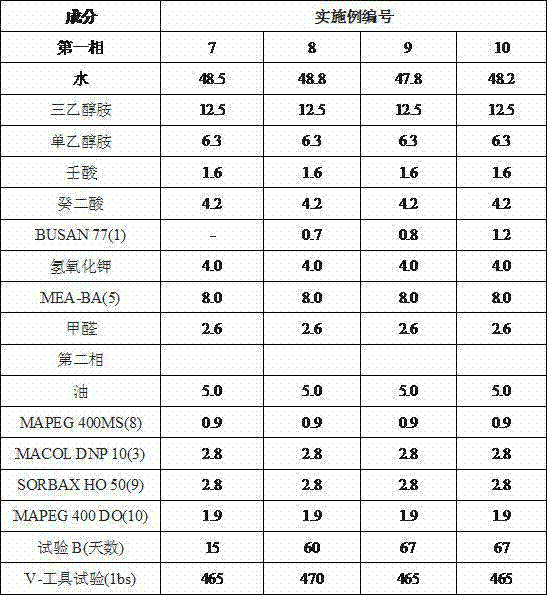

Embodiment 7-10

[0062]

[0063] (8) MAPEG 400MS, polyethylene glycol (MW 400) monooleate, Mazer Corp., MAPEG is Mazer Corp. registered trademark of

[0064] (9) SORBAX HO 50, polyoxyethylene sorbitan hexaoleate, Chemax, Inc., SORBAX is Chemax, Inc. registered trademark of

[0065] (10) MAPEG 400 DO, polyethylene glycol (MW 400) dioleate, Mazer Corp., MAPEG is a registered trademark of Mazer Corp.

[0066] The aqueous machining fluid compositions of Examples 1-10 were prepared by combining each of the listed first phase ingredients with continuous agitation, heating the mixture to 110°F and continuing to agitate until a clear mixture formed , to make the first phase; combine each of the listed second phase ingredients under continuous agitation, heat the mixture to 130°F and continue stirring until a homogeneous mixture is obtained, and make the second phase; under continuous agitation The 130°F second phase was added to the 110°F first phase until a clear homogeneous product was obtaine...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap