A split induction heating gradient heat treatment device

A heat treatment device and induction heating technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve problems such as low work efficiency, inability to perform oil quenching treatment, and inability to directly take out high-temperature discs, etc., so as to improve work efficiency and work high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] This embodiment is a split-type induction heating gradient heat treatment device.

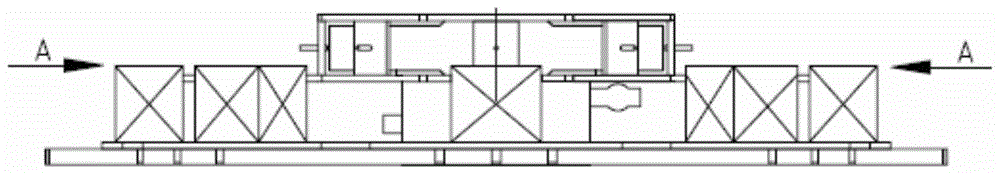

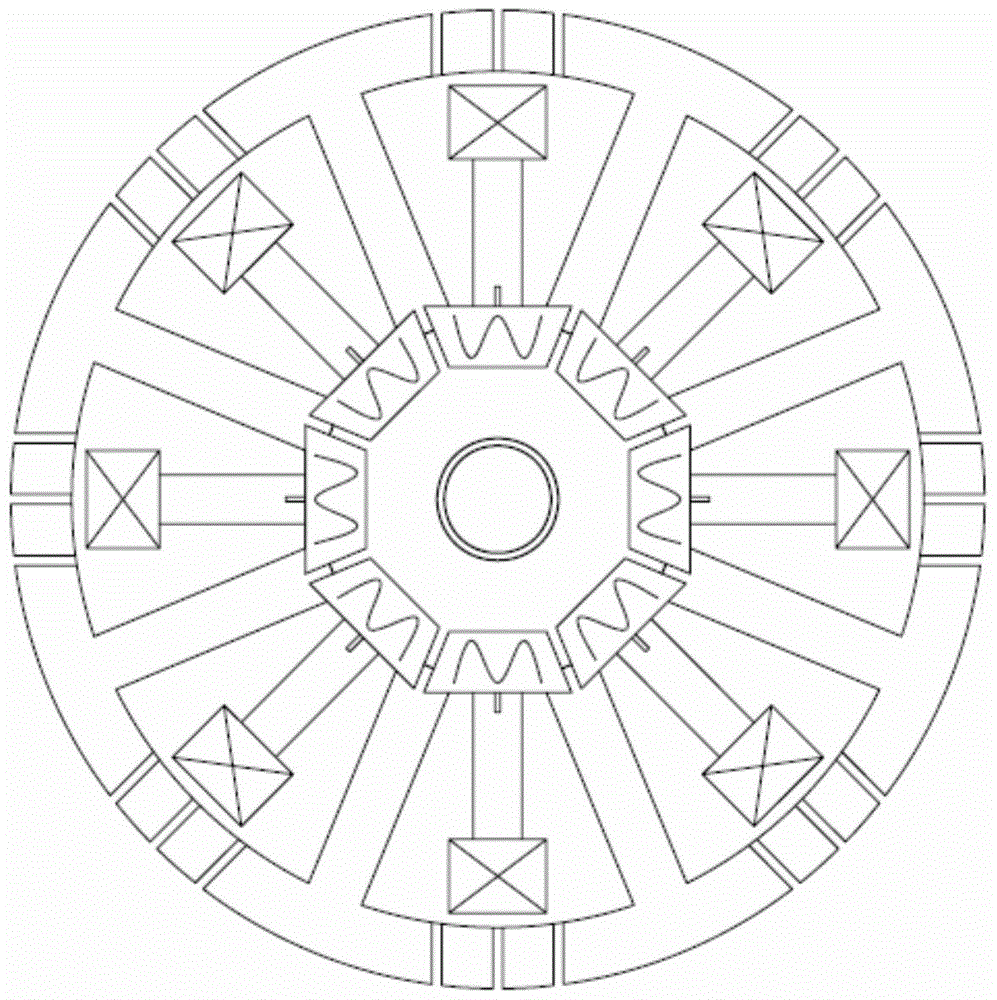

[0021] See Figure 2~ Figure 5 , the split type induction heating gradient heat treatment device of this embodiment is composed of a positioning chassis 1, a cooling box 10, a circulation pump 11 and a plurality of induction heating units; the induction heating units are evenly distributed on the positioning chassis 1, and the cooling box 10 is fixed on the positioning chassis 1 In the middle part of the cooling box 10, the circulation pump 11 is installed outside.

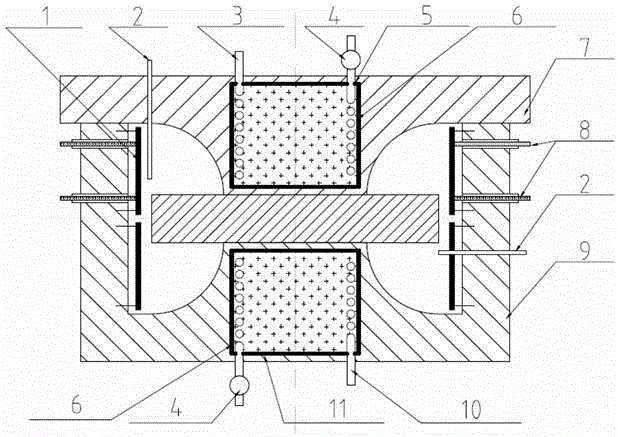

[0022] The induction heating unit includes an intermediate frequency power supply 2, a support base 3, a positioning key 4, a thermocouple 5, and an arm-type sensor 6. The induction heating unit is a frame structure, and the arm-type sensor 6 is fixed on one side of the support base 3, and connected The base 3 is fixedly connected into one; the open end of the arm-type sensor 6 cooperates with the edge of the disc-shaped pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com